Here to "document" this swap and douse the internet with some info in a grey area. For a few years ive ran a briggs opposed in my offroad mower, i know its not the lightest, or most powerful, or most fuel efficent, or blah blah blah, im aware. Its just what ive ran- had good luck at it too.

ANYWAYS, its no secret im a nut about these engines. Ive been in search for the "holy grail" -the pressure lube opposed. Finally- ive gotten my hands on this design in the salvage yard. What do i do now? see if i can shove all that junk into my other rare briggs, a big bore 46ci opposed ive ported and polished.

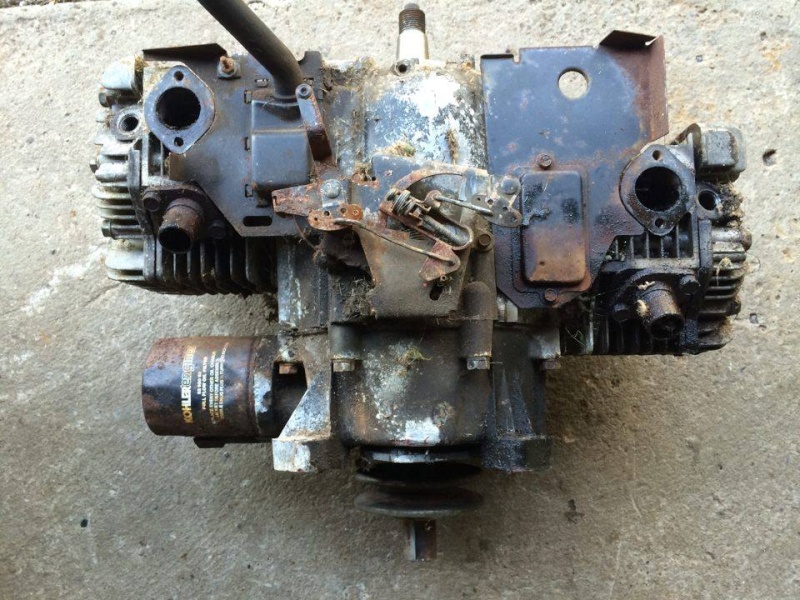

Anyways, heres the longblock i picked up. Unknown year 16hp from a ford hydro.

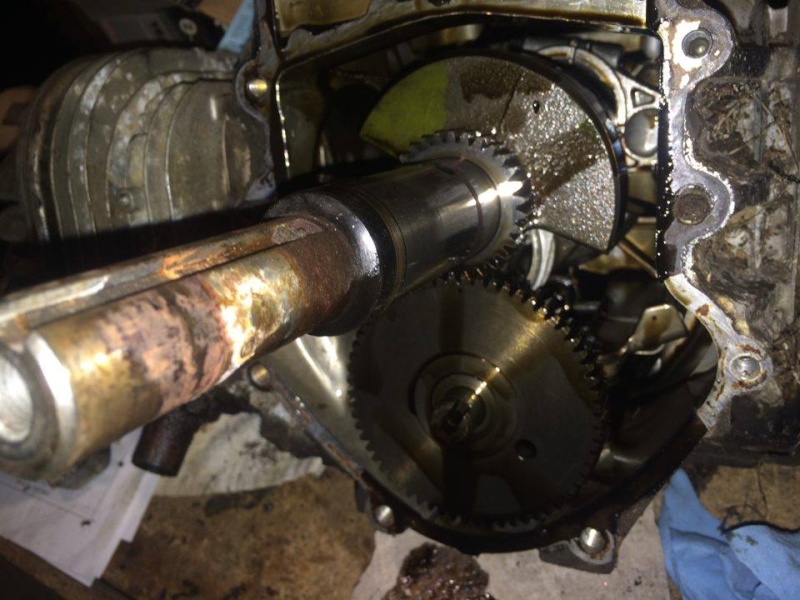

With the base off you can see what ive seen in one manual online-the pickup screen, the pump thats powered by the bottom of the cam (notch in hollow cam) and the tubes that run oil to and from oil filter housing. You can also see crankshaft journal port for oil to flow up into the crank itself.

Lower crank journal oil hole.

So oil gets sent up thru the hollow cam, all the way to the top cam race, where it dumps out into a small tube thats drilled in the block, and travels inside the block to the top crank journal.

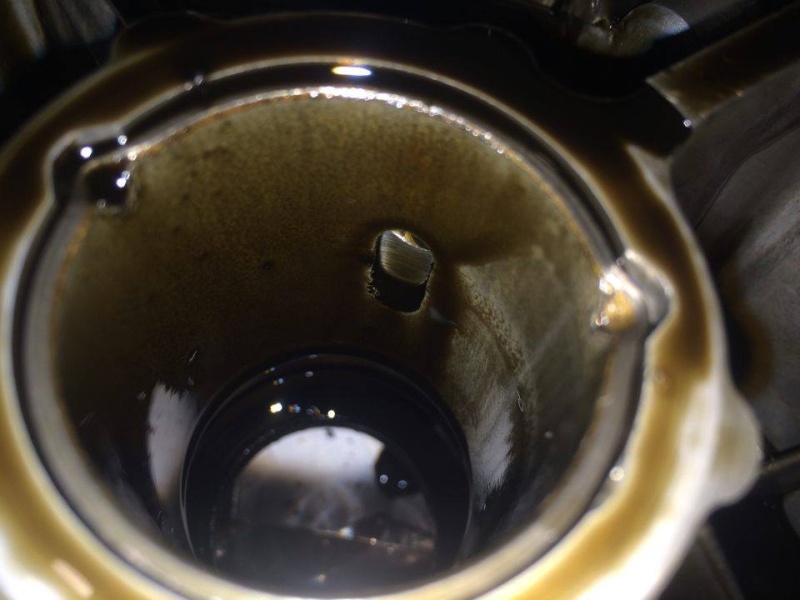

You can barley make out the small hole inn the race.

The factory drills a long 3" or so hole in the block, nicking the top of the cam race causing the small hole. After they drill the plug it.

So the top hole lines up with the crank hole or "dip" you see. that travels within the crank to the rods. Top crank journal hole feeds top rod, and bottom crank journal hole feeds the bottom rod.

Bottom crank hole & rod oil holes.

So, the oil travels within the crank to the rod journals. This is where the rod picks it up, travels within the rod and to the wrist pin. Hole in rod around wrist pin is for the oil to escape.

Entire pressure lube engine apart.

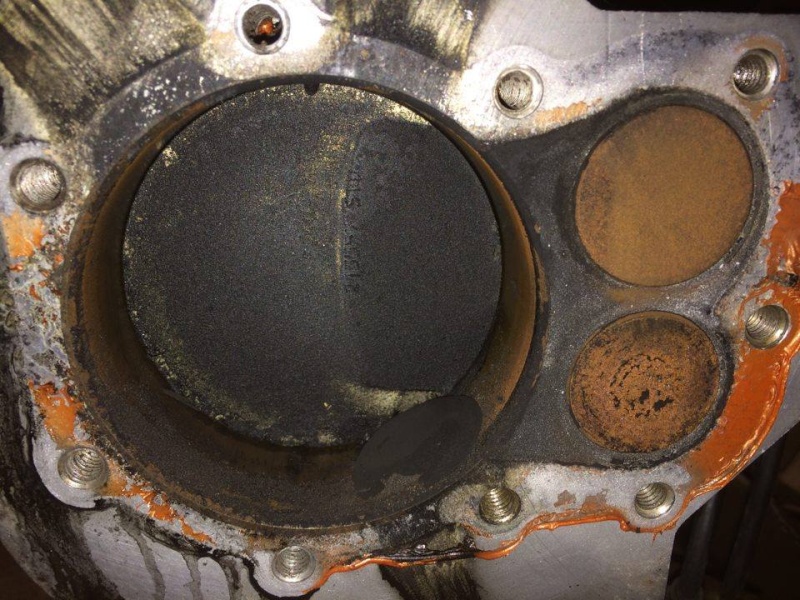

Now, taking my 46 apart. For those who remember i used high temp RTV for headgaskets. I ran it for 5 hours or so romping in PA. Turns out i laid it thin or deck was not smooth and really blew it out on the high cyl. The bottom cyl had a small blow out spot. Ran good too! Could this contribute to a "tick" that i was hearing from compression leaking? I think it is. Lots of carbon everywhere too. Not sure why. Maybe carb way off. Flash rust on valves.

Top cyl, three blowouts.

Bottom, cant really see it.

Still have to pull rotating assembly out of the 46ci. Oil block mods to come, ill update when i get there.