| | 1969 Wheel Horse 700 WORKHORSE |  |

|

+16Rustbucket Garage CraftsmanQuad19 murphyslaw SteamNut247 mr.modified Creepycrawler yeethaw Crazy_Carl Kyracer13 Murraymountain RichieRichOverdrive Double W Cross Ranch AllisKidD21 BlakeGroce MightyRaze mrshaft696 20 posters |

|

| Author | Message |

|---|

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Join date : 2017-10-30

Posts : 2561

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 27th 2020, 5:18 pm March 27th 2020, 5:18 pm | |

| I really like that engine mounting plate with the fuel pump to a remote tank. Yeah wheel horses are geared so low and slow but make great crawlers. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 6:47 pm March 29th 2020, 6:47 pm | |

| Thanks Carl! Yeah I dont really do any fast riding anyways, I like to just sit back relax and crawl along. Ended up doing some yard work today hauled a bunch of busted up concrete. Idk how much it weighed but I piled it up till the tires went flat on the trailer and it had some "mad camber bra!" going on.   | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 7:48 pm March 29th 2020, 7:48 pm | |

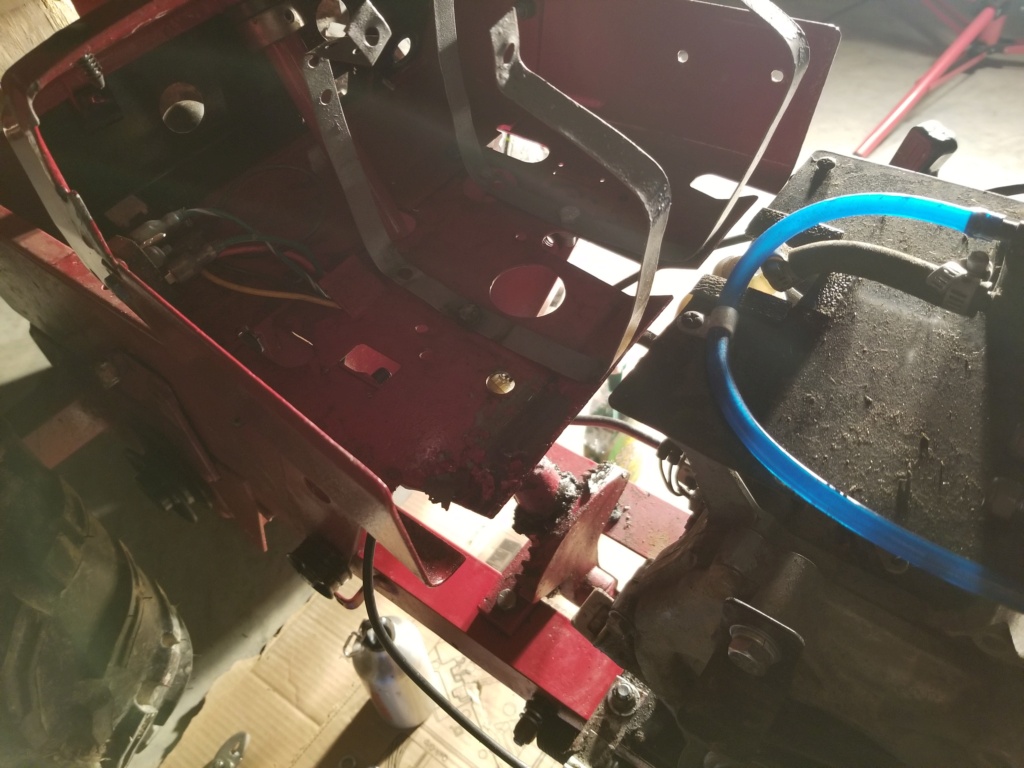

| So I thought I'd show what it takes to turn a generator engine into a usable engine for really anything but in my case my wheel horse. So basically your gonna have to figure out a shaft because the output shaft on generators are tapered so my dad came up with the idea of machining a sleeve to fit over the taper on the crank which would turn it straight. This was pretty tedious but the second go around was a dead nuts fit. You can also use the taper peice that goes into the generator part but in this case it couldn't be turned down to a standard size. The size we thought would work best was 1 and 3/8s. So that's what my dad did and my dad talked me into using one of those split tapered pulleys so that's what I went with. Oh and of course your gonna have to cut the appropriate key way for the shaft size you choose. You can also take the crankshaft out and turn it down to a usable size but this shaft on the honda was too short for that. Here's a picture of the original taper peice thingy that went on the shaft.  Here's a picture of the first shaft my dad made but the taper was off a bit so it didnt work.  Here it is on the tractor right now.  Oh and I was too lazy and cheap to go buy the proper bolt to fit the shaft cause I have no idea what size or thread it is cause its metric so I just cut the long a$$ one off that came with it, shortened it, then welded a 3/8s grade 8 nut on the end of it. So I guess it's a bisexual bolt (3/8s head and metric threads)  but it hasn't flew off and killed me yet so I guess I did good. Lol!  | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5333

Posts : 2561

Location : Rochester, New York

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 8:31 pm March 29th 2020, 8:31 pm | |

| Would you please explain your belt guides on the engine. I have a bolt kinda guide in the same place where you have your top one. I'm currently thinking about putting one roughly where your bottom one is to help my clutch not releasing problem. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 8:42 pm March 29th 2020, 8:42 pm | |

| Another thing you're gonna have to do is figure out the govenor because generators are normally set to run at 3000 to 3600 rpms so what I did was a re-adjusted the governor to where it would idle down then I ended up welding the arm straight because for some reason this honda uses a different govenor arm that has a pivot in the middle. This is where I welded....kinda hard to see so I drew a circle around what I'm talking about.  You're also going to have to get a throttle plate because there is no where to hook a throttle to so I got one off Amazon for 20 bucks but it also came with brand new springs. It didnt come with a cable clamp so I made one out a 1/4 in bolt with a hole in it and a nut. Works good!  I also had to figure out a choke because there is no place hook a choke cable to. This generator had an auto choke but it also had a choke lock out for cold starts so I ended up making a little bracket for a spring to go on then I ended up doing some finagling it to make it work. I really dont know what I did but it works.  looks pretty slick too just pokes alittle out of the hood so you can pull it.   No choke  Choke  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 8:59 pm March 29th 2020, 8:59 pm | |

| - Crazy_Carl wrote:

- Would you please explain your belt guides on the engine. I have a bolt kinda guide in the same place where you have your top one. I'm currently thinking about putting one roughly where your bottom one is to help my clutch not releasing problem.

I had the exact same issues your having. What I did is have someone push in the clutch while the engine idles or lock the clutch in then used two screw drivers and just sat there and pulled up and pushed down on the belt fairly close to the engine pulley till the belt stoped (gotta be careful doing this) but your looking for the belt to grab the screw drive just enough to allow the belt to disengage around the front side of the engine pulley. It's hard to explain but once you get it in the correct spot you just make a bracket that is in the exact spot your scew driver was and then your going to have to fine tune there location and how far they are away from the belt. I will note I have an extra tensioner and my belt guard is homemade to fit my engine so I'm not sure how yours works being a latter model tractor but you have the nice clutch that pinches the belt unlike mine. Hope this makes at least some sense lol but if you have anymore questions just ask away! | |

|

| |

Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5333

Posts : 2561

Location : Rochester, New York

| |

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 9:15 pm March 29th 2020, 9:15 pm | |

| Oh yeah I can up shift pretty well while moving just as long as I let off the gas before grabbing a gear. This is what the 60s models have on the belt guard to stop the belt (I believe wheel horse called it a "belt pucker") but my pulley was too small to use a tang like this one but you might be able to with yours and it looks alot cleaner in my opinion. I'm sure your 702 has one like this.  | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7221

Posts : 4020

Location : Lewisburg, KY

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 9:22 pm March 29th 2020, 9:22 pm | |

| That's a good idea for placing belt stops. I've always just placed them where convenient. Budgie has always been good about shifting from gear to gear, but going to a gear from neutral is a bit iffy if you dont wait. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  March 29th 2020, 9:46 pm March 29th 2020, 9:46 pm | |

| It probably helps that I beveled the edges of the gears in the transmission when I had it apart. I only did it because they were ground down alot and had sharp and rough looking edges. All I did was file them smooth and slightly rounded the edges over since they were chewed up. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  July 15th 2020, 7:47 pm July 15th 2020, 7:47 pm | |

| Well I'm not dead. Haven't done anything to Brutus except use it, but my neighbor gave me this trailer for free the other day so I'm pretty excited about that!  I was gonna build one but now I dont have to! It needs new sides and a floor but itll do for now till I have the time to fix it up.  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  July 15th 2020, 8:05 pm July 15th 2020, 8:05 pm | |

| While I was trying to figure out how I was going to hook up this trailer I noticed that the belt guard was sitting over top of the pulley on the transaxle making my belt rub the belt guard pretty hard.......well it normally rubs the belt guard but this time it's pretty bad.  So at first I though "ok I've hit something with the belt guard and I bent it in some" but upon further inspection I grabbed the transaxle pulley and it moves around on the shaft. So I'm guessing that my set screws have came out or something along those lines. I really honestly dont know how long this has been going on for and I'm really glad it didnt come flying off into the stratosphere while doing mock one. Lol! Even though I dont think it can because of the belt.  | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  July 16th 2020, 4:24 pm July 16th 2020, 4:24 pm | |

| My engine pulley came loose before too. I used locktite on my set screw after that and it's been ok. You might also drill or grind a small divet for the set screw to sit in on the crank shaft. Doesn't need to be a big hole, just a small depression. Only thing is you have to see where it will line up and mark it somehow so the hole will line up with it in the correct spot. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  July 16th 2020, 10:21 pm July 16th 2020, 10:21 pm | |

| Well I found some time today to take a look at it. Found that both set screws weren't even tight.  Also this is how I have my belt routed.  It was rubbing pretty bad on the belt cover for awhile now  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  July 16th 2020, 10:34 pm July 16th 2020, 10:34 pm | |

| I was using my homemade puller to pull the pulley off and got lazy and decided to use the impact and broke the nut off of the end where I had welded it. "Dang it Bobby!"  So I just welded a new nut on there, this time making sure I burned it in good and while it was still hot I quickly stuck it in some water to hopefully harden it alittle. But I got the pulley off and I forgot that we had to shave the back down so it would be inline with the clutch.  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  July 16th 2020, 11:05 pm July 16th 2020, 11:05 pm | |

| I also found that my hubs were alittle loose so I decided I'd look at the set screw...bolt thingy. All I did was grind it back to a point and made sure the hole in the middle was deep enough. If your tractor has these holding the hubs on pull them out every year when you change your oil and inspect them.    So I sprayed everything down with some simple green and wiped it all off with a rag so it's nice and clean. I also painted the pulleys black cause I've been meaning to do that for a while now. But I got it all back together and used some lock tight on the set screws this time.  So I need to also at some point make a new bracket for the belt guard. It was already broke when I got it and I didnt know what it was the entire time I was building it but I'm glad I didnt because it would have been in the way anyways. But it definitely needs some more support in the back so I'm thinking I'll just make a new one that clears everything.....some day. Lol  It's way quieter now. Doesnt sound like it has crickets in it anymore so that's good! Lol! | |

|

| |

SteamNut247

Member

Age : 28

Join date : 2016-12-14

Points : 2978

Posts : 70

Location : Duluth Minnesota

| |

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

| |

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  September 10th 2020, 1:33 pm September 10th 2020, 1:33 pm | |

| Well spend most of yesterday cleaning out the fence row. I like my privacy and all but we had lots of briers and small saplings growing through the fence and they get in the way when your trying to mow. I dont know what type of briers these were but they put up a good fight. They were more like a vine instead of a bush and they wrapped around anything they could get ahold of including myself!  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  October 5th 2020, 8:34 pm October 5th 2020, 8:34 pm | |

| Well the other day I was hauling dirt and decided to climb the dirt pile with the trailer attached......well I did, and bent my hitch extension.  I also drew this super detailed picture to show what happened.  Basically the tractor was going down hill while the trailer was still going up hill.   | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  October 5th 2020, 8:59 pm October 5th 2020, 8:59 pm | |

| Now normally I'd make it more betters but really the only thing better is a ball hitch and yeah it would have helped out but that means that all my tractors have to have a ball to tow this trailer and also all the trailers would have to have a coupler. So I just decided to fix it the best I could and just not climb dirt piles with the trailer attached. I don't have an oxygen and acetylene torch so I just got it as hot as I could get it with map gas (which ain't much) and then bent it back as good as I could with the vise. Before:  After:  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  October 5th 2020, 9:13 pm October 5th 2020, 9:13 pm | |

| I also welded up the extra holes to try to strengthen it up some. It's still a little bit bent so I flipped it over and put the slight bend up so maybe it wont bend as easy.  Got it all primed, painted and put back on!  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  December 28th 2020, 5:02 pm December 28th 2020, 5:02 pm | |

| I think it's about time to do some maintenance on Brutus. I havent really had to do much to it since I got it going but sometime recently it developed a small fuel leak from under the gas tank, not enough to make it unusable but enough that I'm gonna have to fix it, and since I'm going to have to pull the tank out I thought I'd do some other things that I've wanting to do to it for a while now. So I thought I'd make a list of things so that maybe it'll make me motivated to work on it. -Give it a bath cause its covered in mud, dirt, and mold. -Fix the fuel leak -Change the oil (been almost 2 years  ) -Repaint the dash -Paint the engine pulley black -Paint the throttle clamp black -Make a new choke spring bracket out of aluminum -Touch up red paint on the belt guard and anywhere else -Paint the muffler Black -Make a steering wheel cap -Make new gas tank straps (maybe) -Put the battery tray infront of the engine and use it for storage (maybe) Some bigger upgrades that I want to do but might not have time. -Brace the front spindles -Replace the front wheel bearings -Make new beefier tie rods that dont suck -Get some dust caps for the front wheels and spindles -Make a inner belt guard so that everything doesn't get covered in mud and belt material -Maybe make a duel throttle setup but still not sure on that If I think of anything else I'll add to it. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  December 30th 2020, 9:50 pm December 30th 2020, 9:50 pm | |

| Well I got this turd in the garage to work on it. We dont have electricity or anything as of the moment so I'm using extension cords. But I got the gas tank off, came out about like I thought it would, ended up having gas run down my arm like usual.  I'm pretty sure the thread sealer eroded cause when I got the nipple out it completely fell apart. Now I know I could just use some different "better" thread sealer and put everything back together but the more I look the fuel system the more I dont like it. I know it's pretty slick how it has a remote tank and a fuel pump and how everything is nicely routed but it's just complicated for what it is. I would love to have the tank above the engine just like an original honda engine. However, like I've mentioned before I cant use a stock honda gas tank because I dont have the hood clearance to fit an original tank even if I had one. So I thought about buying a replacement honda tank for a smaller engine like a gx200 or something like that. I'm pretty sure it wouldn't just bolt up but has anyone ever used a smaller gas tank in the original location?   Doing this would not only mean I wouldnt need a fuel pump anymore, it would also allow me to have more room in the dash where the tank is now located and have more weight up front. It would be a cleaner and more reliable setup then what I currently have. Pic of the thread sealer gone

Last edited by BlakeGroce on January 1st 2021, 3:13 pm; edited 1 time in total | |

|

| |

murphyslaw

Member

Join date : 2020-12-27

Points : 1497

Posts : 55

Location : Michigan

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  December 31st 2020, 11:20 am December 31st 2020, 11:20 am | |

| This has been a very cool build. Everything has a very clean finished look. Looking forward to seeing what other modifications are in store for the future. | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2518

Posts : 469

Location : Richmond Ky

|  Subject: Re: 1969 Wheel Horse 700 WORKHORSE Subject: Re: 1969 Wheel Horse 700 WORKHORSE  December 31st 2020, 1:45 pm December 31st 2020, 1:45 pm | |

| - murphyslaw wrote:

- This has been a very cool build. Everything has a very clean finished look. Looking forward to seeing what other modifications are in store for the future.

Thanks!  I like to make things clean looking but sometimes I think I over think alot of things and make it way too complicated.  But I should have some more upgrades coming! | |

|

| |

Sponsored content

| |

| |

| | 1969 Wheel Horse 700 WORKHORSE |  |

|