|

| | Thinking about tracks |  |

| | | Author | Message |

|---|

Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Thinking about tracks Subject: Thinking about tracks  April 30th 2019, 1:51 am April 30th 2019, 1:51 am | |

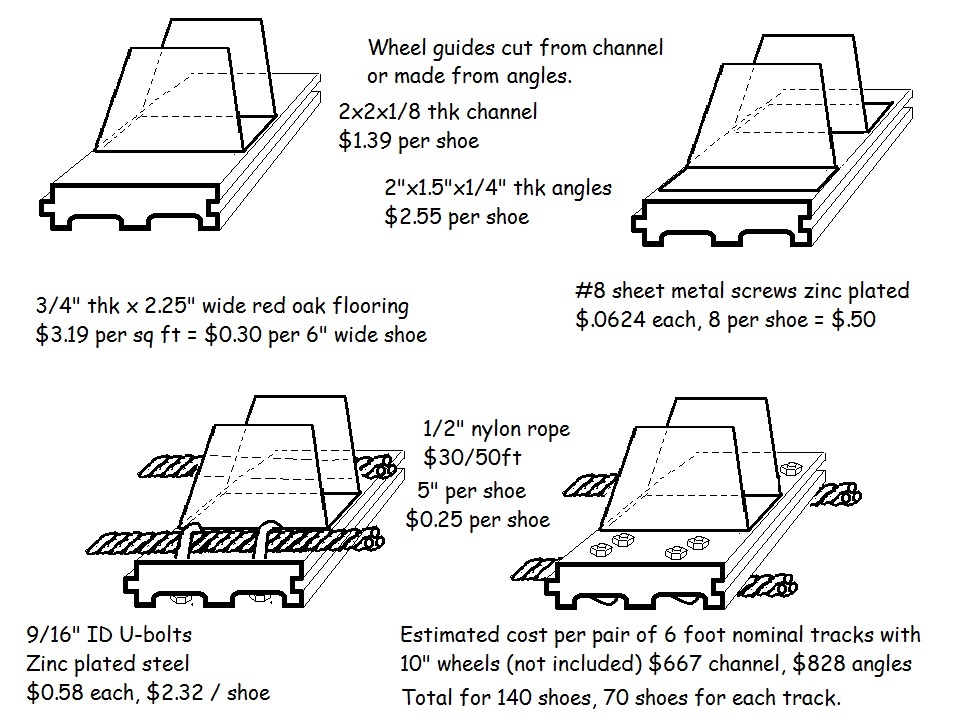

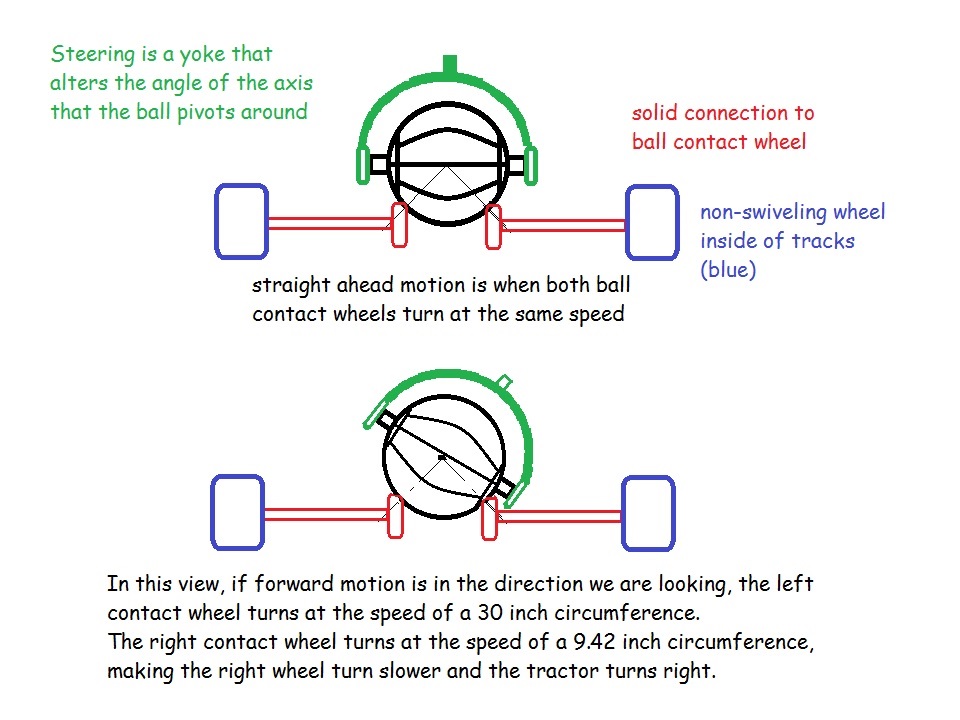

| I'm thinking about making tracks for my craftsman project. It's early, yes, but I want it to have more power. Also I pulled a toy wagon by hand across some of my rocks & slopes and the wheels tended to get stuck on things. The effect of tracks is to emulate a much larger diameter wheel, sort of. They would also make the machine as good as a 4-wheel drive, maybe. So the problem is expense. I have been thinking of using oak flooring to make the shoes, what I'm calling the links in the track-chain. 6 inch long pieces of 3/4 by 2-1/4 oak flooring would cost about $0.30 each. I think 1/2" nylon rope would work well as the chain and hinges that binds the tracks together. I added up a lot of hardware like angles to hold the tracks on the wheels and u-bolts for the rope. The cheapest with metal guides was $1.32 per shoe total. I didn't sketch it but I think guides made from 2x3 lumber would be cheapest and they could be cut to hold the rope hinge too. Shoes made that way could cost $0.824 per shoe, or $115.36 for a pair of 72" tracks needing 140 shoes. The front axle wouldn't turn so a variable ratio coupling is needing between left & right sides. A strong sphere made from a basketball could do that, maybe. Another sketch shows how tilting the axis of a ball could set the speed ratio between the 2 sides. The setup shown could turn on a 2 foot inside radius for a 36" wide vehicle, if it works. Any thoughts, comments, advice? The images don't show to me, I'll try the link after I post this, sorry in advance.

Last edited by Tour1 on April 30th 2019, 2:17 am; edited 1 time in total (Reason for editing : trying to load pictures instead of links to google photos) | |

|   | | Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  May 14th 2019, 2:06 am May 14th 2019, 2:06 am | |

| I made a sketch of a shoe (apparently called a grouser by the wise men) that will use pine 2x3 blocks instead of u bolts or other hardware. This will be the cheapest way. I drew the 2x3 blocks with a curve that matches the 10" tire. It would be quicker to just cut the angle straight and avoid the extra labor. I'll decide that when it gets made, if ever. I would / will also put the b-ball drive on the back shelf. The easiest way to skid steer AFAIK is to make an 8 wheeler with 2 axles between the current ones. then the front axle (becoming non-steering) will be mounted further forward. A wood brake shoe mounted on the existing steering axles will rub on and stop the wheel close behind it when the steering wheel is turned in that direction. These tracks will not be the equivalent of a giant chain saw. They will be more like a recirculating gadget that continuously puts wood slats in front of the tires. The nylon rope is stretchy, I think, and there will need to be a tightening event now and then. (sorry it's late and I forgot how to post an image, but it looks good now).

Last edited by Tour1 on May 14th 2019, 2:45 am; edited 2 times in total (Reason for editing : trying to load pictures instead of links to google photos) | |

|   | | TourMax

Member

Join date : 2018-10-06

Points : 2720

Posts : 438

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  April 20th 2020, 8:12 pm April 20th 2020, 8:12 pm | |

| Not to be a buzz kill, but you’re putting too much effort into it. Lots of the 6x6/8x8 guys just grab an old snowmobile track, split it in half and put the “retainers” inside the track. Like so: http://www.6x6world.com/forums/tire-track-wheel-talk/20262-home-made-rubber-tracks.htmlMy Argo has snow tracks and it operates via skid steer through a differential coupling inside the transmission:  If you’re running tracks and don’t plan to have steering wheels (like a half track), you need differential braking for skid steer. Theres no other way to turn a track vehicle other than skid steer. By the way, the pieces the tires run in are commonly termed “shoes”. “Grousers” are on the outside of the track and they look kind of like “cleats” for added traction:  On tracked amphibious vehicles, grousers are also used to offer additional propulsion through water by acting like “paddles”... | |

|   | | Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  April 21st 2020, 3:21 am April 21st 2020, 3:21 am | |

| I joined the 6x6 forum before finding the ATLTF forum. At the time there weren't any affordable-by-me skid steer toys for sale. If your Argo is newish it sells for way more than 100X the Craig's list mower I got for $50. So I'm winging it one step at a time using pocket money.

The tracks I am thinking about making are for a slow vehicle that would be a generator mounted to a frame from a high end running machine. I think my brother in law backed into the not-working running machine in a parking lot behind a retail building he was working on. The guy who owned it made him buy it for $100 so it cost twice as much as my lawn tractor.

So anyway there's a thread here somewhere about a lawn tractor with split snowmobile tracks. I just don't have a snowmobile. I'll do my best if and when I work on this.

Thanks for the info and references, though. I once had a boss who had served in the tank corps under Patton. All he told me about tanks was how BS the tank scenes in the Patton movie were. | |

|   | | TourMax

Member

Join date : 2018-10-06

Points : 2720

Posts : 438

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  April 21st 2020, 9:00 am April 21st 2020, 9:00 am | |

| Most guys just keep their eyes out for worn out/takeoff tracks. They are often found pretty cheaply, since they're not good for much of anything else. You’ve probably seen the other home made track options if you frequent 6x6 world. Everything from conveyor belts to steel links. You imagination is pretty much the only limit. My 8x8 is a 1986 I/C. Its older, but you are right that it cost “just a wee bit” more than 50 bucks. I actually paid 3500 cdn for it and it was in pretty bad shape. They’re hard to find here and when you do guys want wasaaay too much for them. Anything you pick up super cheap ende up needing EVERYTHING replaced or repaired. I ended up “refreshing” the engine and transmission, mostly for my own peace of mind. I also had to replace all the chains, seals and bearings. Thats somewhere around 50-60 feet of double row #50 chain. All the sprockets and axles were seized solid and it took me a couple weeks to just get it all apart. I had to beat up/cut some parts so badly I had no choice but to machine up new pieces. Was one hell of a rotten job that I never want to have to do again...ever. The Argo was bought in this condition:   And after more time, money and PITA than I want to think about, it looks like this:    Theres a bit more done to it as those pics are a bit older, but thats most of it. Have you ever driven a skid steer before? It takes a pretty specific way of controlling it so it does what you want without trying to throw your brain against your skull or burst a kidney. Tracks can also be the biggest PITA ever if they’re not made exactly right. It doesn’t take much to be the difference between tracks that work and tracks that are always being thrown at the worst time... | |

|   | | Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  April 21st 2020, 10:48 am April 21st 2020, 10:48 am | |

| I took a test ride at an Argo dealer in Chambersburg PA if I remember correctly. The salesman drove but he went up and down the embankment of a sump they have there. It was close to I-81 near Maryland.

Some of my constraints or wish list, maybe, are:

1. under 900# trailering weight

2. able to climb steep hills

3. cheap to buy or easy to build

4. easy to get on/off/in/out

5. can carry a passenger

6. can plow gravel (even a little is ok)

7. less than 4 feet wide

There are other options, like buying a new trailer, building a cable car, paying $8K for engineers to design a driveway that goes up the hill. For now I am stuck down-state and I started repairing the mower deck.

Drifting away from my home-made tracks topic.

Thanks for the posts, though, the members here are great at minding their own business ;-)

| |

|   | | Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5328

Posts : 2561

Location : Rochester, New York

| |   | | prancstaman

Veteran Member

Join date : 2015-02-02

Points : 5091

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  April 21st 2020, 6:20 pm April 21st 2020, 6:20 pm | |

| I can see the tracks working if the guides on the sides were straight up, because you want the tire to slide the track sideways when turning or the tire will ride up the curved side and throw the track. I would look into using cables to connect the track, instead of any kind of rope. The basketball drive system is in the old zero turn mowers. Just have to find one to use it.

Just my take on things. Hope it helps.

| |

|   | | Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  April 22nd 2020, 11:08 am April 22nd 2020, 11:08 am | |

| Wire rope is more expensive, I think. Plan A was to use thick rope like for ships and it would be enough to keep the wheels in the tracks, again too expensive. 2 U-bolts per shoe adds a lot of hardware although it's the simplest.

I'm hoping affordable rope will stretch just the right amount to function as a suspension system. One adjustable axle could set the initial tension. The tractor can't likely pull much more than its own weight in actual applied force no matter what. My tracks would serve more like recirculating boards for the tires to roll on, with built in ramps to climb stuff bigger than the tires.

Also there's no need to float in deep water, my hill is 400 feet vertical distance from the river. Horizontal distance is more, | |

|   | | Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

| |   | | Rustbucket Garage

Veteran Member

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2021-01-15

Points : 2877

Posts : 1340

Location : Upstate New York

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  March 22nd 2021, 8:25 am March 22nd 2021, 8:25 am | |

| How long of a track do you need? A 22.5 semi truck tire will give you about 9 1/2 feet total length, so figure 3 feet of track length if you are aiming for 18" height. You also could simply rivet two or more tires together for extra length. (or something, not an expert on rubber) I'd go to local tire shops and they would probably give you a set of bald car tires for dirt cheap (truck tires are harder to get cheap cause they are usually retreaded) Hope that helps. | |

|   | | Tour1

Member

Join date : 2019-03-15

Points : 2190

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Thinking about tracks Subject: Re: Thinking about tracks  March 22nd 2021, 12:34 pm March 22nd 2021, 12:34 pm | |

| I live within a few blocks of junkyards and scrap yards so it shouldn't be too much trouble to find stuff like worn tires. It's more trouble to prioritize things. Anyway I like the tire-tracks and the other guy's hitch based cantilever track suspension. | |

|   | | Sponsored content

| |   | | | | Thinking about tracks |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 15 users online :: 0 Registered, 0 Hidden and 15 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|