|

| | HD MTD (Honda Driven) |  |

| | | Author | Message |

|---|

mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: HD MTD (Honda Driven) Subject: HD MTD (Honda Driven)  February 1st 2015, 10:27 am February 1st 2015, 10:27 am | |

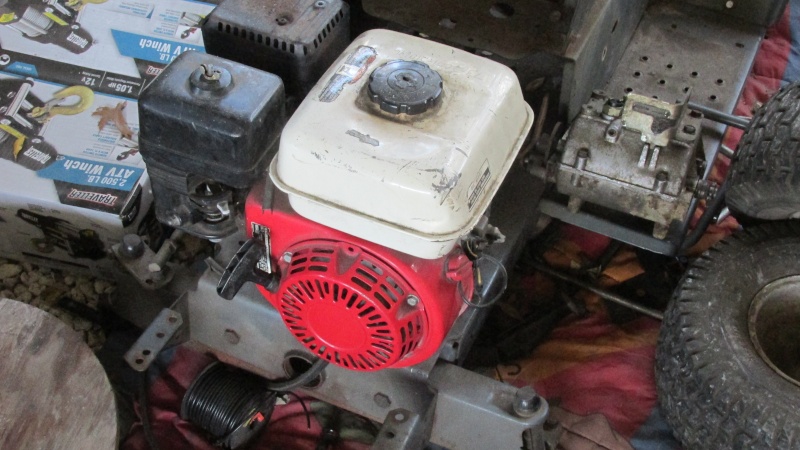

| i will be editing this for the most up to date build progress

Parts that i started with:

Honda GX160,

20" and 15" TIRES

mtd FNR axle,

Peerless 700 (Modified),

lightly modified MTD frame.

some MISC peerless MST parts (Not in first pic)

To Do:

Drive train

new crank for Honda (has been cut short)

modify peerless 700

clutch

drive shafts

lock FNR

mount FNR

make couplers

exhaust

batter intake

Car alternator

Extensive electrical

Low oil Alert

Improve front steering

improve front suspension

12V outlet

on-board air compressor

rear skid plate

12V to 120V converter?

Done:

Last edited by mudman604 on February 5th 2015, 9:57 am; edited 4 times in total | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | Doc Sprocket

Site VIP

2018 Build-Off Entrant

2018 Build-Off Entrant

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2016

1st Place Build-Off Winner 2016

Age : 51

Join date : 2013-04-21

Points : 7318

Posts : 2914

Location : Ontario Canada

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 1st 2015, 10:54 am February 1st 2015, 10:54 am | |

| This is certainly going to be a build worth watching... Welcome to the competition! | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 1st 2015, 12:46 pm February 1st 2015, 12:46 pm | |

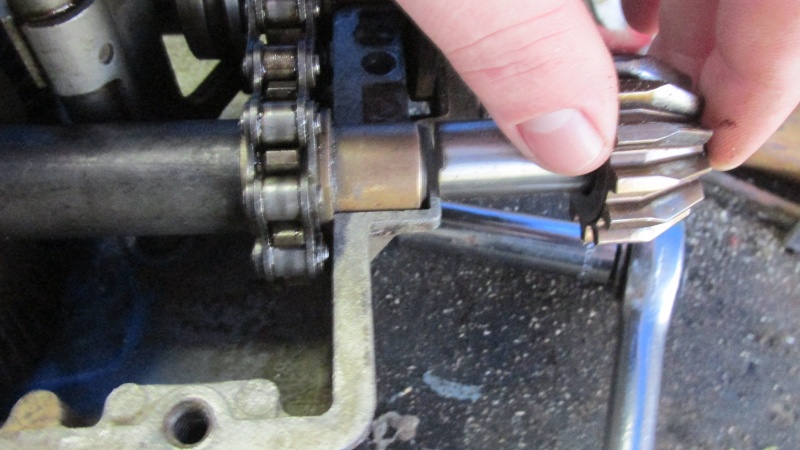

| Parts: Honda GX160, 20" and 15" TIRES, mtd FNR axle, Peerless 700 (Modified), lightly modified MTD frame. some MISC peerless MST parts (Not in first pic) other things to do if i finish the drive train: car alternator, a extensive eltrical system (Especualy fo a pull started engine  ) low- oil ALERT. upgrade and improve front steering better front suspension 12V outlet on-board air compressor 12V converter? the whole idea is to have an auto motive style drive train. with a custom IN-line tranny (Meaning not changing the orientation of the shafts.) then a rear diff, i wont do rear suspension, because of how it will need to be set up.   engine will sit about here, with belt and clutch behind it.  then this will be mounted like a rear diff, will probly lock it.  peeress sits about here  the pearless, i bought for 10 bucks, because the input was blown out. ive pluged the hole with an old brake disk, some steel skix, by JB Weld, and some blue RTV, i will convert it to oil, but i need to get a shift fork.    it is a five speed, in good shape, i plan to use this old axle 3/4', for my drive shaft, at least one,   so, the idea is to extend the input of gear shaft to make it an input, and use an old input from the MST for the splines and to use the gear as a coupler. first i will grind out one side of the case to open it up, then weld on the shaft that will be shorter than whats shown   again, i will use the splines to make couplers that will be on the end of the shafts. i will try to draw up some concepts to make it clearer.  \ wow, it took about 25 minets to do this...................  SOME TIME LATER ok, went out and cut open the bearing.   now about extending the shaft, does anyone know if there is an avalible extended shaft? if there isent here is my plan/ideas. 1, since its hardened steel, no drilling unless i can find capable bits, so the idea is to do a coupler/sleeve. in this pic, that is represented by the old bearing  then mount an over sized bearing that runs on the coupler. thoughts, ideas, need some help because this is the hardest part. the coupler cold be spline on both ends so it splines up with the old reverse gear splines, then shrinks down to the out put spline sand takes up about half of them. so then its a no weld.

Last edited by mudman604 on February 2nd 2015, 10:26 am; edited 1 time in total | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

| |   | | GenevaCustoms

Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2013-09-24

Points : 4415

Posts : 315

Location : Florida

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 2nd 2015, 6:39 am February 2nd 2015, 6:39 am | |

| Use the peerless 700 that way will still allow you to have gears? That is awsome, want to see this finished up | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 3rd 2015, 10:05 am February 3rd 2015, 10:05 am | |

| ok, went out to heaven yesterday, (TSC) and got:

1x 5/8' ID 7/8' OD 1.5' hardened steel sleeve.

1x 7/8' bearing and housing

1x 3/16' (i think) cobalt drill bit

1x tube of RTV (Saw it, thought, Mine is almost out....)

need to get gear oil.

so, ith bit is to drill a deeper hole in the new input shaft (the one in the tranny). i had an idea and i will test this tomorrow, im in my schools engineering academy. so i have access to some slightly better equipment. my idea is to lathe out a 3/16 rod (or whatever the size is) part way from the shaft peace i am using to extend it, so then the rod gets hammered in to the old input, then welded, then smooth it out, then weld the sleeve over top of it. to mount the big A** bearing, i will grind out more of the side of the case, use one of the old brake holes, and drill another and make a spacer. then up top. to seal it, the idea is the bearing housing will be very close to the case, so i could maybe seal it up with RTV. i will prob make a vent (if i can get the neutral safety switch out)the reason im going to lathe out the rod from the extension, is so it can be precisely 90 degrees and is perfectly center. (all this depends if the lathe can cut this hard steel.) then, its to mount the engine if this works, then tranny, then rear diff, (after i lock it) ill post pics later tonight

going to drive my jeep up to tarpon FL from Hudson to hopefully sell it.

Also How do i measure bold holes on a 4 hole rim? | |

|   | | 802 Customs

Member

Age : 25

Join date : 2015-01-08

Points : 3758

Posts : 146

Location : Vermont

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 3rd 2015, 6:10 pm February 3rd 2015, 6:10 pm | |

| Sweet transmission mods! Will be interesting to see how this pans out. | |

|   | | mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

| |   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 4th 2015, 7:19 am February 4th 2015, 7:19 am | |

| - mr.modified wrote:

- Center to center I guess for 4 bolt wheels.

thanks alot | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 4th 2015, 9:55 am February 4th 2015, 9:55 am | |

| Had an idea if the CNC can cut the steel, (the one at my school) , I could re-use the old reverse gear and make a super low gear for crawling in the old spot. Put a supper small gear on the input and the biggest gear I can find . use the CNC to carve out the middle of the old sprocket and the middle of the new gear and weld them together. Make it a 6 speed no reverse (I'm going to use the mtd fnr for a revers) | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  February 5th 2015, 6:41 pm February 5th 2015, 6:41 pm | |

| Factory lightening holes in the transmission gears... I would drill a bunch of holes through my gears if I wasn't already planning on drilling holes through everything else. Gonna take long enough as it is. Probably hard steel to drill through anyway. | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | Craftsman1998

Veteran Member

2014 Build-Off Top 3 Winner

2014 Build-Off Top 3 Winner

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2013-10-30

Points : 5152

Posts : 1068

Location : New jersey

| |   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  March 5th 2015, 6:50 am March 5th 2015, 6:50 am | |

| U haven't made or done any thug because our welder needs a new cable. Idk how long it will take, I hope soon | |

|   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

| |   | | mudman604

Member

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 26

Join date : 2014-12-03

Points : 3781

Posts : 110

Location : hudson FL

|  Subject: Re: HD MTD (Honda Driven) Subject: Re: HD MTD (Honda Driven)  June 8th 2015, 8:46 am June 8th 2015, 8:46 am | |

| OOOOOOOOKKKKKKKKKAAAAAAAAYYYYYYYY. FINALLY got to work a bit. im out of school for 2 months, so something should get done. i got the new input shaft welded at the ford dealer, so that's not going to break, lol. i have a new idea for the rear drive, my friend has an old toro with a pearless 700 and a differential axle. i coudl buy it, use the 700 as a high-low transfer case. not a 4x4, thats another project im working on. mount it with the original input facing towards the front of the tractor, and then run a chain fron the output to the diffed axle.and im thinking that i could engineer something to make it a selectable locking diff. i would make the transference a 2 speed forward and 1 reverse. i would use the original 1st gear for low and the original 5th gear for high range. so low would be ABOUT 7:1 , and high would be 2:1. These are guesses, i don't have my hands on this pearless yet. that idea would give me 10 selectable speeds, more than i need, i could have 25  if i use all 5 speeds in the soon to be transfer case. we were able to get the old hub off of the engines crank, so i don't have to get a new crank. i will upload some picks later. | |

|   | | Sponsored content

| |   | | | | HD MTD (Honda Driven) |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 27 users online :: 0 Registered, 0 Hidden and 27 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|