| | Utility MX |  |

|

+9redzz02 Deluxe66 Thunderdivine redlinemotorsportts jamcco jonjunk willis923 Doc Sprocket MoMower 13 posters |

|

| Author | Message |

|---|

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Utility MX Subject: Utility MX  August 24th 2014, 3:21 am August 24th 2014, 3:21 am | |

| Here is my recipe to make utility tractor: - take 8HP engine out and put smaller engine in. I know that usually swap should be done in vice versa - low speed but big enough towing torgue. - one idea is to use motocross tyres  - make an pile of stuff from garage and mix it and then weld it together. Seriously I do not have an final plan about the end result. Yarman is new utility platform   It has variable speed pulley. If someone has good insructions how this works please inform where information is found because this tractor was already in some parts when it game to me. I would like to use this pulley at this tractor.  When this is ready I am able to make bigger modification to the "silver thingy" because I would like to have save tractor for the youngsters and would to go more offroad with the "silver thingy". I have no imagination about the titles

Last edited by Deluxe66 on September 1st 2014, 11:42 pm; edited 1 time in total | |

|

| |

MoMower

Member

Join date : 2014-06-25

Points : 3841

Posts : 37

|  Subject: Re: Utility MX Subject: Re: Utility MX  August 29th 2014, 10:34 am August 29th 2014, 10:34 am | |

| Got me. But good luck with the build. | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 2nd 2014, 12:18 am September 2nd 2014, 12:18 am | |

| Thanks luck is needed. I do not understant the meaning of "got me" but never mind I do not understant your language 100% anyways. Now I have decided to use MX tires. My plan is to use car rims 12" in front and 14" in rear. I will cut an slice the rims and then weld it together so that widht is suitable for MX tires. I will use honda 4hp engine from push mower with variable speed pulley. I will put parts back to the Yardman frame and try to figure out how all was working and the try to make it work on my custom "tractor". Plan is to add car alternator. There is at least two ways in my mind. I will most likely make intermediate shaft and put an car alterantor to this shaft and I will use another belt from intermediate shaft to the variable speed pulley. Or I will use different belt for the alternator. I will deside the final assembly later. At this moment I would like to have the alternator as high as possible. Frame is open should I use Yarman or make totally new. Engine in front or rear? I ususally make quick decisions right afrter I have time to weld something  Now I used the area where brain usually are and changed the project name  | |

|

| |

Doc Sprocket

Site VIP

2018 Build-Off Entrant

2018 Build-Off Entrant

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2016

1st Place Build-Off Winner 2016

Age : 51

Join date : 2013-04-21

Points : 7318

Posts : 2914

Location : Ontario Canada

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 2nd 2014, 6:53 am September 2nd 2014, 6:53 am | |

| - Deluxe66 wrote:

- I do not understant the meaning of "got me" but never mind I do not understant your language 100% anyways.

"You've got me" is slang for "I don't know". Be mindful of the alternator's power requirement, it can easily consume a couple of horsepower at full amperage output. Your proposed engine is quite small, this may be a problem. Why eliminate the 8hp you have? | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 2nd 2014, 7:58 am September 2nd 2014, 7:58 am | |

| Ok thanks.

I will use that 8HP engine to the front blade of type mover.

Alternator is for light usage. But maybe I need forgot about it and use battery led light for examble | |

|

| |

willis923

Veteran Member

Age : 28

Join date : 2013-04-10

Points : 5761

Posts : 1408

Location : Galway NY

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 2nd 2014, 1:30 pm September 2nd 2014, 1:30 pm | |

| i would go LED if possible. they consume WAY less power, and burn brighter AND longer. | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 7th 2014, 2:15 am September 7th 2014, 2:15 am | |

| Some decision have been made. - I will use scooter battery + some 12v led light. I have used this compination on my mountain bike. Lot of light and I have already tested that battery is enought for at least 5 hours on winter also. - I measured car 14" rim + tire and also 14" MX tire + rim => MX tires with inner tube seems to be possible. I will use car steel rims so it is lot easier to modify. At this moment I have decided to use car rims on rear. Front has two optios at this monent. Next I will try to find Scooter 12" rim and compare it to 12" MX tire. Scooter rim is aluminum + it has disk brake. This compination should be the easiest way to get good grip to fron wheels also + the brake issue. Yesterday we started to remove all the parts off the frame.  This morning my 3 year old son asked that can we go an ride with the red tractor  . This time had to say that no can do. After frame is clean I will start to put some parts back so that I get the vari drive idea. Honda engine is now running. I have removed the blade. Next thing is somehow to fit the pulley and also figure out the diameter. I need to study the 8HP rotation speed. Please inform if you know how much is 8HP B&S max rotation speed. I already know the Honda data. I think I can calculate the final speed after all rotation speeds are known. I assume that Yardman max speed has been close to 6 miles / hour. Please inform if I can find some speed data from internet. More ideas are inssside my head put this time I try to focus on these open issues. | |

|

| |

Doc Sprocket

Site VIP

2018 Build-Off Entrant

2018 Build-Off Entrant

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2016

1st Place Build-Off Winner 2016

Age : 51

Join date : 2013-04-21

Points : 7318

Posts : 2914

Location : Ontario Canada

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 7th 2014, 10:53 am September 7th 2014, 10:53 am | |

| Normally, the engine's maximum no-load speed is governed at 3600RPM. This is generally true amongst all engines of this type. | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 9th 2014, 12:54 am September 9th 2014, 12:54 am | |

| Thanks for the information.

Final speed calculation:

- Honda data sheet says max 2900rpm so it is o,8 times smaller compared to 3600rpm. Honda has 3,7kW so it is close to 5HP not 4HP as I informed before.

- 14" Mx tire is 1,5 times bigger than Yard-Man original tire.

- I will use similar size pulley on engine.

- quick calculation gives final speed 6 miles / hour x 0,8 x 1,5 = 7,2 miles / hour.

I will be happy if the final speed is around 7 miles/ hour. Small drivers => low speed. Low speed => better torgue.

Yesterday I opened my garage door and it also opened my eyes. There is so much open project that this Utility MX is going to be as fast build as possible. Engine is going to be at rear and I will try to use Yard-man original parts as much as possible.

Frame, rear and front axles are now pressure washed. Yesterday I temperarily installed rear axle back to frame. I copy the honda engine installation holes so that I am able to drill holes to the yard-man frame. I found almost similar pulley that 8HP B&S original was and this pulley is going to honda engine.

Next I will install all those original parts back that has something to do about the tractor moving. I will take apart all parts that are somehow connected to blade and put those at garage corner waiting for some other use. | |

|

| |

Doc Sprocket

Site VIP

2018 Build-Off Entrant

2018 Build-Off Entrant

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2016

1st Place Build-Off Winner 2016

Age : 51

Join date : 2013-04-21

Points : 7318

Posts : 2914

Location : Ontario Canada

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 9th 2014, 7:35 am September 9th 2014, 7:35 am | |

| Would you mind linking me to that data sheet? 2900RPM is rather low, compared to "normal". I suspect you can safely turn the governor up on that one. | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 10th 2014, 5:07 am September 10th 2014, 5:07 am | |

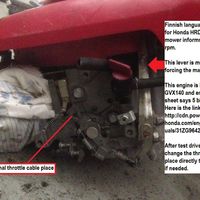

| Good that you asked about the data sheet. Finnish language data sheet for the push mower says max 2900prm. There was also the type of the engine and it is Honda GVX140 and after I typed that to google it gives english data sheets with different value 3600rpm. So you were correct. Here is one link for excamble http://cdn.powerequipment.honda.com/engines/pdf/manuals/31ZG9642.pdf. Here is photo from the carburetor area  As I wrote to photo after test drives I will modify the throttle cable position if needed. Honda engine with 3600rpm is similar to B&S so only 1,5 times bigger tire gives higher speed. If this tractor goes too fast I will increase the rear axle pulley Today I drilled new holes to the Yard-Man original engine mounting plate. Now I should be able to bolt the Honda to this plate and this plate with Honda should fit to original Yard-Man frame. I also tryed to drill the holes so that Honda crankshaft is at the same posisiton as B&S originally is. My plan is to swich Honda and B&S engines to the frame so that when I am making seat and other parts the original B&S engine also has enough space. I think this is good idea for the future. If I some day want to have bigger engine there is already B&S suitable mounting plate and also space enough.  Next issue is to fit the pulley to Honda. I have already measured what height should I aim. This sketch has some finnish language and mainly is for me so that I can found info easily. Now I only need to make it work   | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 12th 2014, 2:41 am September 12th 2014, 2:41 am | |

| Plate is now ready for Honda and I just quickly lifted engine + plate to Yard-Man frame. All seems to be okay.  | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 17th 2014, 12:42 am September 17th 2014, 12:42 am | |

| Well I accidentaly received 16" aluminum car rims and decided proceed with plan B or C I do not know anymore. I also ordered 4pcs 16" MX tires. Someone has already had fun driving with those at track and some corners are bit rouded. I would still say that those are closer to turf shaver than saver. 16" MX tire outer diameter is about 22,5". I do not know what you think but I am going to make this way. I started by cutting the rim. Originally this is 7" wide and table says that MX wheel should be 1,85" wide.  Arter couple of minutes it was in pieces   I had to make an quick layout test    It seem that I need to cut little from rear fenders. I migh need to cut a bit from front frame or I need to limit the wheel turning angle  Next I need to figure out how to weld rim back in one piece. Most likely some problems are on the way but usualyy those can be solved somehow. | |

|

| |

jonjunk

Member

Age : 31

Join date : 2014-03-21

Points : 3976

Posts : 66

Location : Montrose, MN

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 17th 2014, 8:10 pm September 17th 2014, 8:10 pm | |

| Very cool I've never seen mx tires used should be very good traction. | |

|

| |

jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4216

Posts : 226

Location : New Hampshire

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 17th 2014, 8:40 pm September 17th 2014, 8:40 pm | |

| this is very unique, Very interested in seeing how mx tires work as a set, instead of being on something "one wheel drive" | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 19th 2014, 1:57 am September 19th 2014, 1:57 am | |

| Thanks lot of work but I hope that end result is just the way I want. I tryed to instal tire to wheel but at this moment it is impossible. I need to take away material from the center of rim because rim is now straight.  I have also made some progress with the engine pulley. I have now widened the pulley for bigger belt. I have chinese lathe and that is very useful for many times.  Yesterday I took a little look at the frame and axles. It seems that I will make this "tractor" wheel to wheel dimension wider. I do not know how to explain it better but plan is that I take the origal tire off and leave the rim to axle. After that I will weld steel plate with car rim bolt pattern inside of original rear rim. I will post photos as soon as this is done. Front axle needs also some modifications. These tires needs big space for turning and I need to have same place for my feet also  | |

|

| |

MoMower

Member

Join date : 2014-06-25

Points : 3841

Posts : 37

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 19th 2014, 10:13 am September 19th 2014, 10:13 am | |

| Good luck with it. I've got four tires I just have to swap and I hate it. Lol. Need a tire machine. Can't wait to see how this looks on yours. | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 22nd 2014, 4:52 pm September 22nd 2014, 4:52 pm | |

| Thanks luck is needed and good hand muscles. Lot of work with grinder on those rims. Here is quick layout test with front tires also. You migh see a bit difference to the original tire sizes. I kind of like the look  .  I also put the original "bonnet" on the top I might use that as fenders?  From this picture you might have some idea how I am going to install the car rim. I just weld an extra plate inside of original steel rim. I will post better photos after I have that plate welded.  Hopefully I have managed to create an link so that you are able to open these photos bigger on aijaa web page. | |

|

| |

redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7483

Posts : 3131

Location : raleigh nc

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 22nd 2014, 6:36 pm September 22nd 2014, 6:36 pm | |

| The plate that you are going to make, id suggest to make as close to the center as you can. Like so:  Less stress on the axle and cleaner look. Just a suggestion, the tires are pretty cool, im interested to see how they perform. | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 23rd 2014, 2:14 am September 23rd 2014, 2:14 am | |

| As always my plan is valid only the time I or someone else figures out better solution. Now I think that I will use the grinder also to the steel rims  According my plan there is little more that one inch between Yard-Man steel rim and the plate I was intending to weld. Less stress and cleaner look is the winner thanks. It is easy to make more space to the Yard-Man frame for the rear wheels. I have to add steel tubes to the frame Next I have to figure out what kind off hub I am going to use on front. I have already make an drawing for custom made hub with ball bearings. More use for the lathe and end result should be strong enough for even lot bigger tractor. Faster way to the finnish line is that I will add atv trailer hubs to the shopping cart and it is done. just waiting for the delivery to come  . I assume that original Yard-Man front hubs will bend under the tractor at the first obstacle I will try to climb. I know me and I will try to drive over an mountain if that is on my drive way  | |

|

| |

MoMower

Member

Join date : 2014-06-25

Points : 3841

Posts : 37

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 23rd 2014, 9:52 am September 23rd 2014, 9:52 am | |

| I love those tires. And that is gonna look awesome. I'm now wondering about it turning and the tires contacting the frame. How much room between inside of front tire and the frame? | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  September 23rd 2014, 3:34 pm September 23rd 2014, 3:34 pm | |

| Thanks front wheel turning agle is one open issue at this moment. I need to cut the front frame for sure and weld an subframe from steel tube. Hopefully I do not need to modify the pedals up and over the front wheels  One solution is to add turn brakes  I will also widen the front wheel to wheel widht and just hope that turning agle is going to be big enough so that I do not need an airport to make an u turn. I have got lot of inspiration and ideas from this forum. Thanks for helping and please feel free to give ideas and also keep "questioning" freely my ideas in future also. I am still at learning age  | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  October 2nd 2014, 5:22 am October 2nd 2014, 5:22 am | |

| Now I have one rim ready for take two.  Rim is now welded from both sides and I also grinded an groove to the midlle of rim for easier tire installation. Hopefully tire will slip to the rim this time. Other three rims are cutted and ready for welding. Before any welding I will try to install the tire to this one rim I have desided to use inner tube but if this is somehow hard or impossible I might use something that is thicker than air => spray pu foam  | |

|

| |

Deluxe66

Member

Age : 47

Join date : 2014-05-23

Points : 3961

Posts : 120

Location : Finland

|  Subject: Re: Utility MX Subject: Re: Utility MX  October 6th 2014, 4:46 am October 6th 2014, 4:46 am | |

| all right some progress. Tire slipped to the rim.  Original rims are cutted  Next I will try to install the tire + rim compination with inner tube. I have only 18" inner tube but I think that is good enough for testing. If it works then I will get right size inner tubes. | |

|

| |

redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7483

Posts : 3131

Location : raleigh nc

|  Subject: Re: Utility MX Subject: Re: Utility MX  October 6th 2014, 4:03 pm October 6th 2014, 4:03 pm | |

| Looks good man, really skinny. Should look really sporty | |

|

| |

Sponsored content

| |

| |

| | Utility MX |  |

|