|

| | W.H.A.M.S. |  |

|

+11kawasaki220 Moose redlinemotorsportts Creepycrawler willis923 Doc Sprocket 1997 Murray B440 craftsmancole LAWN MOWER MUDDER Angchor 15 posters | |

| Author | Message |

|---|

Angchor

Member

Join date : 2014-04-14

Posts : 491

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 20th 2014, 11:33 pm July 20th 2014, 11:33 pm | |

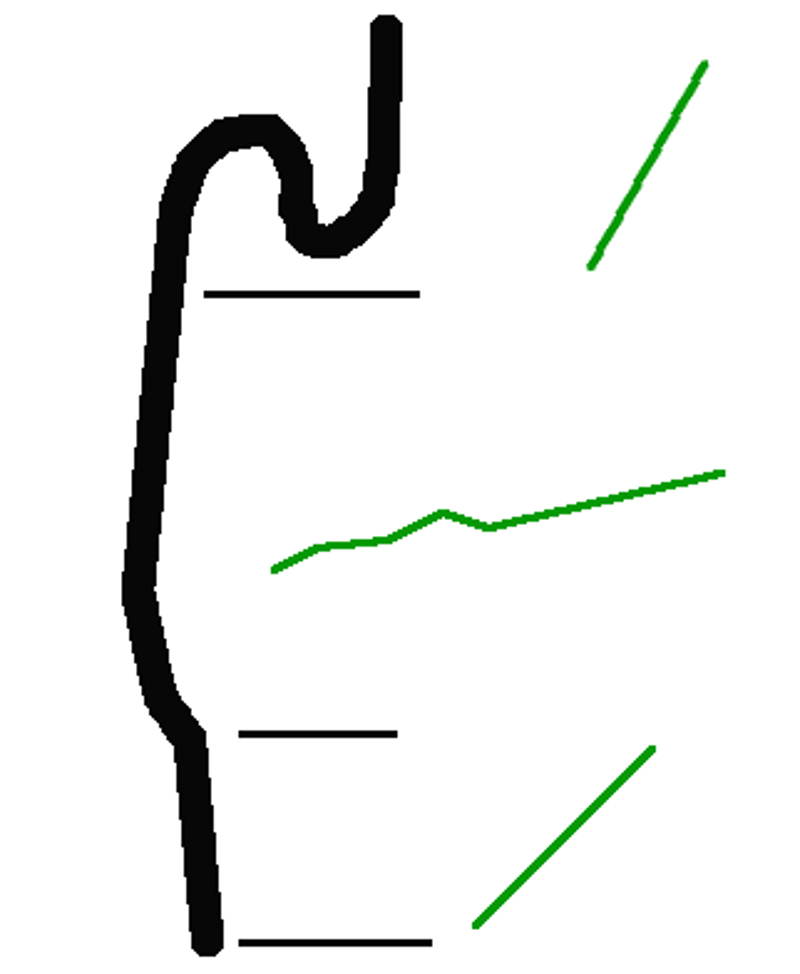

| Ok, this one is frustrating. I have adjusted the shifter many times. Each time, closer and closer to the center. Until I now have it pretty much dead center. If you look at the pic... The red arrow points at a bolt. If you loosen the bolt, then you can move that arm either direction, as the green arrow indicates.  With it bolted tight, when you move the shifter arm, up above, this moves back and forth in the same direction, but it also moves the rod in the background in and out of the trans, in the direction of THAT green arrow. The problem is that I have adjusted this shifter as close as I can. It is in the center. But not. Because where it is, you have to really pull on the shifter and hold it forward, to get the trans to actually GO into forward, and to stay in forward. Undo that bolt, and move it just a HAIR, and I mean just a hair, the other way, then tighten it down, and now it will do forward just fine, but now it won't stay in reverse. There is just absolutely no way to adjust this thing any finer than I have done. But there HAS to be a way! Is there a trick to this that I am not catching on to? | |

|   | | RCTankboy

Member

Join date : 2014-04-02

Points : 3928

Posts : 39

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 21st 2014, 11:58 am July 21st 2014, 11:58 am | |

| Please correct me if I am wrong but, shouldn't wheelie bars be rigid?

When I have watched funny cars or drag bikes race; the wheelie bars are rigid and have no compression of any kind.

I worry that if you fab up a wheelie bar that uses those shocks; your going to putter up the hill one day, hit something that pops the front end up and the wheelie bar will compress and it isn't going to keep the front end down or thing from landing on you again. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 21st 2014, 4:58 pm July 21st 2014, 4:58 pm | |

| - RCTankboy wrote:

- Please correct me if I am wrong but, shouldn't wheelie bars be rigid?

When I have watched funny cars or drag bikes race; the wheelie bars are rigid and have no compression of any kind.

I worry that if you fab up a wheelie bar that uses those shocks; your going to putter up the hill one day, hit something that pops the front end up and the wheelie bar will compress and it isn't going to keep the front end down or thing from landing on you again. Good point. Here is what I have been thinking... This would be built to pretty much always be on the ground. Most of the time acting like a trailer. Shocks and pneumatic tires will make it more or less a 'second suspension' and will minimize it's effect on the tractor itself. But that suspension would have a dead stop. Where, it would travel only so far upward and stop. After that, it is strictly a wheelie bar. All that said, I am once again leaning toward just making some sort of plain old wheelie bar. Using big wheels off of a push lawnmower. We'll see.... ~~~~~ For now, I still need to get the shifter working right. And then I need to see what I can do about giving it more guts for climbing the hill. Here is a crude drawing of the ATV trail that I have to climb, if I need to bring in supplies from town.  Right at the bottom, it is very steep. It is more than 45 degrees. That is a tough climb for everything that tries it, but given a good running start, it is passable. In the middle, (and the picture shows it a lot shorter than it is, because I didn't want to make a HUGE picture.), the slope varies, but is mostly just like any other ATV trail you are going to find in a forest or someone's back 40... At the top... If that were made into a single shot from where the curve starts, to the top, it would be over 65 degrees of angle or more. Instead, it is made into an "S" curve. To 'lessen the angle of attack'. This is the most dangerous part of the trail. It is not a long, sweeping curve, it is very tight. As a result, you have steep angles not only going up, but steep angles on the curves as well. There was damage at the beginning of that curve, on my way up. I swerved to avoid the damage, but couldn't let up on the gas, or I would lose momentum, and would not make it up the steep grade there. So, the front wheel of the tractor caught some other damage in the trail, and that was that. The tractor was going to go where it wanted to go, no matter what. The front end made a VERY sharp turn, while travelling upward... Met the sidewall of the curve in the trail... And just kept climbing, until it finally flipped backwards. To most of you young cubs, this would just have been an adrenaline rush. You probably would have jumped clear. Cussed about the damage to the tractor. And been just fine. For me... Well, I make a whale look like it's been to weight watchers. I am old. Slow. And overweight. For you, the beast would probably be an adventure. Your age, weight, and reaction time makes you safe. For me, I need the safety to be in the tractor itself. And just wait until you see what this WHAMS is starting to look like!!! It is beeeeyoooteemonious!!!!! I'll post a pic later. For now, I need to eat, take my insulin... Then see what I can do about the shifter and getting some GUTS into the WHAMS! | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 21st 2014, 5:39 pm July 21st 2014, 5:39 pm | |

| Ok, I couldn't resist posting a sneak peek.  Look how wide that rear end is now! The 'wheelie bar' wheels are the big wheels from a push mower. Solid, not pneumatic. And once I build a frame for them, they'll sit back farther, and be off the ground by maybe 4 inches or so. I'm trying to eat quickly, because I am anxious to get back out there and work on it again. LOL The shifter I will eventually figure out a solution for. That is not a worry. Whether it will have the strength for the job or not, is the real worry. I guess that it if comes right down to it, I may just delete the vari-drive. Put on a long belt. Then make my own clutch pulley setup, and just use the clutch and the throttle, to vary the speed. It's not like I need to have 7 different distinct speeds... It looks like the engine is capable of idling pretty low. And I can put in a foot throttle to override the gov, if I need higher speeds. But just getting up the hill is the task. Not getting up at breakneck speeds... It DID pull the beast up a small slope, using a rope and pulley. So I am not giving up on it yet. Ok, lunchtime is over. Time to get back to work. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 21st 2014, 10:42 pm July 21st 2014, 10:42 pm | |

| Ok, progress! Factory instructions on those shifters...  Loosen the bolt. Set the shifter above, to neutral. make sure the rod going into the trans is in the neutral position. Centered. No play, in or out. At the linkage at the red arrow, that top piece will slide sideways. What you want to do is to hold the bottom piece in place, then slide that top piece it as far as it will go, either direction, then half that, and tighten the bolt back down. I followed instructions to the tee! Still will not shift into forward or reverse, depending on which direction you adjust that linkage, just a hair, where the bolt is. Conclusion: It simply isn't going to work. Either the linkage inside the trans is worn a bit, or the linkage outside, is. Maybe a bit of both. Solution: Simple. I just removed the plastic bezel on top of the fender, and cut the slot longer, for reverse.  I laid the plastic bezel back on there, so you can see how much farther I had to cut the slot in the metal. I may now cut the plastic to match, and bolt it back on there so I have a positive stop for nuetral. But I don't see a lot of urgency to that. I also may instead, cut the slot in the metal larger on the forward side as well. Then cut the slot in the plastic, right out to the edge, in both directions. (Leaving enough to hold it all together.) Then see if I can play with the adjustment enough to make that work. But all that is work for later. Right now, it works, and I am happy to move on from this. Once I had that done, I had the confidence that I wasn't going to get stuck somewhere because it wouldn't shift. So I took it for a test drive. Yeah, it goes slow. It has seven speeds. 7. Pretty good walking speed. 6. My ankle hurts. 5. Hangover. 4. Really slow 3. Slugs are looking at you in their rearview mirror. 2. Yo momma making her way through the buffet line. 1. Mollasses at the north pole in january.... But it made it all the way down to the bottom of the trail. And at least just carrying me, and having no hood or other weight... it actually made it back up, pretty good! Slow I can live with. Getting stuck is simply not an option. I'll experiment with making it faster, later on. For now... It has passed my testing well enough to make me want to finish it. And so far, all this is without a custom gas pedal or in any way bypassing the governator. So next up will be the wheelie bar. Then I need to get the battery situation dealt with. Get the hood back on and lockable. Get some racks on it so I can carry water and groceries. And get the chain and padlock bolted in somewhere. At some point in there, I MIGHT take the tires off the beast, and put them on the WHAMS. They are slightly larger, (wider). And they are much more aggressive. And scavenging of the beast has officially begun. I moved the cable setup for charging the battery, over from the beast to the whams. Next might be the battery tray. No use in wasting that, by leaving it in the beast. ~~~~~~~ Ooooooh, I've just been sold on the solid mount wheelie bar, for safety and at this point, for simplicity, because I have so many other things to do. Here is a link to an article about wheelie bars on competition pulling tractors... http://gardentractorpullingtips.com/wheelbar.htmKeep in mind that I don't need a wheelie bar for flat ground. I can control wheelies, there. The times I am going to need the wheelie bar, are times when the tractor is already at a steep climbing angle. So I will have the wheels pretty far apart. And they will not be far off the ground. What I think I'll do is to make a crude and adjustable setup, then make some trial and error runs, to see what sort of adjustments are needed. Here is the "stack-o-parts" that I put together tonight, to start to get some idea of what I am actually going to be able to make.  | |

|   | | RCTankboy

Member

Join date : 2014-04-02

Points : 3928

Posts : 39

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 22nd 2014, 7:32 am July 22nd 2014, 7:32 am | |

| That was a ton of posts, and awesome reading. Your map helped me visualize your trek and your problems. Youre doing it only partly for "fun" and mostly out of necessity. Let the youngin's hill climb. Ol' folk need ta be more careful cuz we break easily and gettin back alive takes longer.

" old. Slow. And overweight." - Yeah, I feel the same way here. Wife says I am 45 going on 85 the way I talk sometimes (she's 8 years older -shhh!). of course that doesnt stop her from asking me to move something heavy up and down the stairs ever month or so.

I love your shifting solution. Perfection in simplicity.

With gearing that low\slow, you should be able to pull stumps if you have traction!

I am going to find a pair of those axles you have for a 4wd tractor. I am dying to build one after the Pistol is done. A nice diesel, 4wd tractor setup for fording and rough trails. YUS!

Wheelie bar: Those plastic wheels scare me. Would you like some metal ones with rubber tires on them, free? I have several sizes. From the standard eight inch tractor front wheel to some 12 inch ones with bearings I never used. Let me know.

Loving this thread. More motivation to go another round with bondo and the electric sander tonight on my own tractor. | |

|   | | B440

Member

Join date : 2014-01-22

Points : 4201

Posts : 226

Location : Thompson, CT

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 22nd 2014, 12:44 pm July 22nd 2014, 12:44 pm | |

| lol, thanks for the ribbon. You don't actually need wheels for the wheelie bar.  Just a metal plate would do. Wheels are for when you need to ride out the wheelie without making extra friction. Do you want to pull a wheelie and continue riding it up the hill, or will you stop, back up a little and try another run at the hill? | |

|   | | kawasaki220

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 23

Join date : 2014-01-22

Points : 4568

Posts : 546

Location : north carolina

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 22nd 2014, 2:45 pm July 22nd 2014, 2:45 pm | |

| you know that all wheel steers are the most dangress tractors to go up hills its happened to me if you pull a wheelie the side of the tractor with the most weight will turn the wheel and it will tip sideways if you dont understand what im talking about just tell me and i will make a drawling of it | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 23rd 2014, 1:52 pm July 23rd 2014, 1:52 pm | |

| - RCTankboy wrote:

- I love your shifting solution. Perfection in simplicity.

Simple solutions are my favorite. Strange thing is, the simplest solutions sometimes take the longest time to get to. LOL (Contemplation on the "why" of the solution, moving things around in your head, etc.) - RCTankboy wrote:

- With gearing that low\slow, you should be able to pull stumps if you have traction!

Unfortunately it's not just gearing. It's inherent loss in the belts and pulley system. I hope to do some reverse engineering and re-engingineering in that area, at some point in the near future. - RCTankboy wrote:

- Wheelie bar: Those plastic wheels scare me. Would you like some metal ones with rubber tires on them, free? I have several sizes. From the standard eight inch tractor front wheel to some 12 inch ones with bearings I never used. Let me know.

Thank you VERY much for the offer! But if you don't live next door, it would take so long to get the wheels here in the mail, that the bridge would be finished by then, and I'll be doing this just for a hobby. I have been concerned about those wheels, as well. Here is a pic of the wheels I have found as replacements. I think they are more like 8 to 10 inches. I'll go measure them in a bit. They are old caster wheels from a huge industrial cart. And they are HEAVY. I'd rather put less weight on the back of the tractor, not more. But considering the use, I think it'll be ok.  I took the 'frames' off of them. Just using the wheels. - B440 wrote:

- lol, thanks for the ribbon.

Thanks for the thanks. Given some of the responses I've gotten before, I worry that people don't really care about the details, and I am being too wordy. - B440 wrote:

- You don't actually need wheels for the wheelie bar.

Just a metal plate would do. Wheels are for when you need to ride out the wheelie without making extra friction. Do you want to pull a wheelie and continue riding it up the hill, or will you stop, back up a little and try another run at the hill? Correct. But I need the wheels for exactly that reason. A plate would slow me down, and I need to keep the momentum to make it up the hill. If I had to stop, then I'd have to back down, and start over again. And backing down that hill is more dangerous than just plowing on through, forward. - kawasaki220 wrote:

- you know that all wheel steers are the most dangress tractors to go up hills its happened to me if you pull a wheelie the side of the tractor with the most weight will turn the wheel and it will tip sideways if you dont understand what im talking about just tell me and i will make a drawling of it

I'd already noticed that. It certainly takes some getting used to! If it gets to be too much of a problem, I'll just disconnect the steering from the back, and bolt the axles in place. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 26th 2014, 4:22 pm July 26th 2014, 4:22 pm | |

| Well, here she is, boyz! Do I win the contest?      I took it for a test drive down the trail and back up. It works fine. Now I can cut off the excess axle, and do some welding on the frame. As well as drilling more and bolting more. I went to town and got some 7/16 bolts to act as the axles for those other wheels. They didn't have any locknuts for them, so I grabbed what they had. Some of those all metal, pinched type jobbies. Got home, and found out that the pinch jobbies, even though I had grabbed them out of the 7/16 bin... Were for 1/2 inch. So I had to revert back to the big wheels again, because I had no nuts for the 7/16 bolts. Moral of the story, always triple check anything you buy from bins at Lowes. I checked and even halfway double checked. Yet I somehow missed that. I wish that customers would put things back where they found them, instead of just tossing them in the general vicinity. I also put the hood on, and made a battery tray with hold down. I took that big metal bumper off, and bolted on a piece of wood, instead. Also put on a harley davidson muffler pipe. So now all I have to do is to solidify this wheelie design. Put a rack or crate or something on, somewhere. Bolt the chain on, somewhere where it can't be easily unbolted. And this thing is ready to be used on a regular basis. | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4233

Posts : 337

Location : Woodville Al

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 26th 2014, 5:37 pm July 26th 2014, 5:37 pm | |

| Looks good like it ecept for the lil white rock on the ground behind the rear tire on the bottom pix its out of place.  Those nuts (jobbie thingys) are called stover lock nuts work better than nylon lock nuts especially in high temp areas the nylon will melt our and no longer be a lock nut. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 27th 2014, 8:51 pm July 27th 2014, 8:51 pm | |

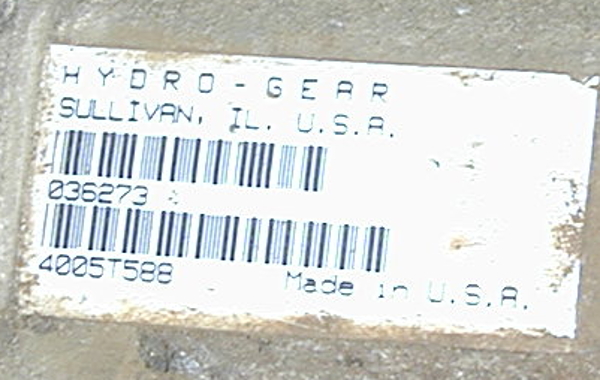

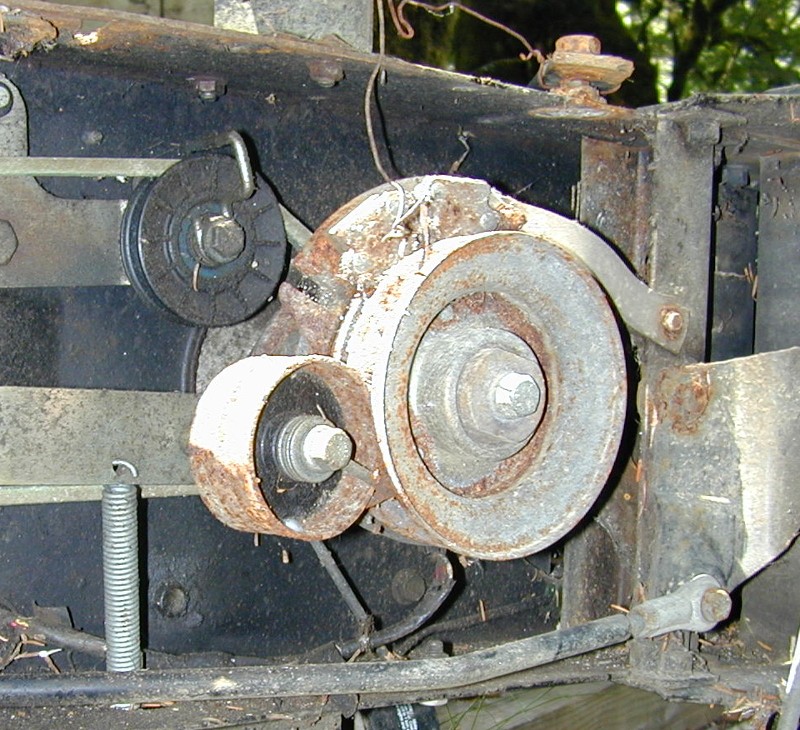

| Ok, this one is almost done, but not quite. I tried to use it to get some work done on the property today. While it barely worked, it showed a couple of problems. Brakes. As in, it has none. But that is not because the brakes don't work. As a matter of fact, they do. Much to my surprise! But I have to push the clutch pedal too far forward for me to reach, to be able to activate the brakes. I'll be adjusting the clutch pedal and linkage so that I don't have to push so far. Hopefully that will not just trade one problem for another, as happened when I adjusted the linkage for the speed shifter. Another problem... Those tires just will not get the job done, if I am working on the property. Last problem, it just feels like I am going to tip over backward when climbing a hill. Now I know that a large part of that is that I am now really hinky about that feeling, because the beast tried to kill me twice, that way. And I know that I have that wheelie bar behind me. But MAN... I have GOT to stretch something and end up with the drive wheels BEHIND me, and not under me. I will be working on the adjustments for the clutch and brakes, and the wheelie bar, for the next couple of days. But after that, I am going to be working on something different. I will be stretching one tractor or the other. The candidates... The beast, which will never see use again, UNLESS I stretch it and widen it, and lower the center of gravity.  And an old Ariens tractor that sat in the back 40 for many years after the PO abandoned it.  ~~~~~~~ I was leaning toward the beast, because it is one that I am familiar with. But now that I have pulled the ariens out of that hole and had a look, I don't know. I may prefer that one. It has a hydrostatic trans which I am not too sure about. I do like the looks of the axle shafts. Pretty beefy compared to the beast. But I am not sure how well these trans work for pulling and other utility work. The wheels were hard to turn with it in nuetral and the wheels free of the ground. Not like the wheels on a manual trans are hard to turn. It was different. Like they were trying to turn through heavy grease.   It already has a fairly small pulley on the trans. You know how some tractors have an electric clutch on the big pulley on the front? (For the mower deck drive belt.) This one seems to have some kind of constriction band type manual activation. Maybe not. But it looks like it. I'll know better once I get into it.  And the engine was full of grey sludge. So I might actually end up having to put the engine from the beast onto this one, if I build it.Bottom line though, this one looks like it may actually be simpler than the beast. Enough about these other ones for now. If I decide to start the build, I'll give it it's own thread. I'll probably name it something simple like Aaron. | |

|   | | B440

Member

Join date : 2014-01-22

Points : 4201

Posts : 226

Location : Thompson, CT

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 10:11 am July 28th 2014, 10:11 am | |

| I didn't look at previous posts to see if you mentioned it, but how about a ROPS (Roll Over Protection System)? It's just a large hoop of steel that is taller than you while you're sitting on the tractor. That way you would feel more comfortable about leaning back on the hills. | |

|   | | willis923

Veteran Member

Age : 28

Join date : 2013-04-10

Points : 5758

Posts : 1408

Location : Galway NY

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 10:30 am July 28th 2014, 10:30 am | |

| - B440 wrote:

- I didn't look at previous posts to see if you mentioned it, but how about a ROPS (Roll Over Protection System)? It's just a large hoop of steel that is taller than you while you're sitting on the tractor. That way you would feel more comfortable about leaning back on the hills.

thats a ROPS. poor mans roll cage as i call it. structurally, i dont know that it would do much. i would trust it with a lawn tractor, but thats it. nothing bigger. if i was making a hill climber, i would load the front tires, maybe make a weight rack, and if i was still concerned, then fab up a ROPS | |

|   | | LAWN MOWER MUDDER

Established Member

2014 Build-Off Top 3 Winner

2014 Build-Off Top 3 Winner

Age : 23

Join date : 2013-04-08

Points : 5206

Posts : 913

Location : Central Pa

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 11:34 am July 28th 2014, 11:34 am | |

| Honestly for your case a hydro would work better than a gear drive. Gear drive systems can be jerky when letting out the clutch. A hydro on the other hand will be smooth (usually) when you move the pedal or the hand control lever. Most cases the hydro will also return to neutral when you let off the speed control lever/ pedal. That way if you were to fall off it would stop instead of keep going like a gear drive with a standard clutch.

Also about the hydro turning really hard. Most hydro-static trannys have a dump valve. You have to pull the dump valve to push or pull the machine manually. That is probably why it is turning really hard. | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4233

Posts : 337

Location : Woodville Al

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 12:49 pm July 28th 2014, 12:49 pm | |

| I agree with LMM. But if your going to use a hydro you something heavy duty. Not just any LT hydro something like a YT or a GT hydro. But if the aarins has a plow on it and trans is still good i would be a lil suprised. But if it do work may be a good trans to use. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 3:55 pm July 28th 2014, 3:55 pm | |

| - B440 wrote:

- I didn't look at previous posts to see if you mentioned it, but how about a ROPS (Roll Over Protection System)? It's just a large hoop of steel that is taller than you while you're sitting on the tractor. That way you would feel more comfortable about leaning back on the hills.

That would be nice. But beyond my resources. Plus, for anything like that to be sturdy enough to be worth anything... (I'd hate to roll, and end up just being crushed/pinched inside a cage whose intended pourpose was to protect me from same. LOL) You'd have to have a VERY strong frame, and you'd have to build from the frame, and not the fenders or other body parts. A bit more complicated than I care to get into at this time. Maybe some time in the future, though... - willis923 wrote:

- thats a ROPS. poor mans roll cage as i call it. structurally, i dont know that it would do much. i would trust it with a lawn tractor, but thats it. nothing bigger. if i was making a hill climber, i would load the front tires, maybe make a weight rack, and if i was still concerned, then fab up a ROPS

I did move weight out front. I put a full sized deep cycle battery out there. Two large pieces of very heavy angle iron. Etc. I also agree with whoever earlier said that any weight I put out front just adds weight to what is falling on top of me, if it succeeds in tipping over again. And my compromise on the cage, is to have at least built the wheelie bar. BTW Something I mentioned at Southern Offroad Mowers, but haven't here, yet... This wheelie bar is because of the steep hills. That makes it's length pretty much optimal. Shorter, would simply make it the new tipping point, because the tractor is already sitting at such an extreme angle. The lower bar is "unistrut". The upper is 1/4" angle iron. (The old stuff. Much stronger than the new stuff.) And the length from the back of the tractor is between 26 and 29 inches. And the bigger wheels makes it less prone to digging in and slowing you down. - LAWN MOWER MUDDER wrote:

- Honestly for your case a hydro would work better than a gear drive. Gear drive systems can be jerky when letting out the clutch. A hydro on the other hand will be smooth (usually) when you move the pedal or the hand control lever. Most cases the hydro will also return to neutral when you let off the speed control lever/ pedal. That way if you were to fall off it would stop instead of keep going like a gear drive with a standard clutch.

Also about the hydro turning really hard. Most hydro-static trannys have a dump valve. You have to pull the dump valve to push or pull the machine manually. That is probably why it is turning really hard. LMM, first I have got to say that you and Redline both impress the heck out of me for having such knowledge and understanding at your ages! It's one thing to be able to just repeat what you have heard from others. But much better, you guys actually understand the "why" of things. That line in my sig is pretty much referring to people like you guys. You are making me excited about getting to work on the hydro. LOL Thank you for the info. I am going to go look for the 'dump valve' today. Then I need to find better information about the actual make and model of it. I do have some info already. But I'll leave all that for it's own thread. ~~~~~ Ok, I have been working on these out of NEED. But now I am hooked. LOL I'll go on working on tractors from now on, as a hobby if for no other reason. But I will go on having need of a good safe tractor. Maybe in even worse conditions than I have had on that trail. Just getting work done on my own steep property. So, what have I learned in all this? The best solutions for these conditions are to stretch the wheelbase, by moving the rear axle backwards. Widen that axle. And lower the center of gravity by lowering the seat. I didn't do that, because it seemed like such a huge task, and I needed it done yesterday, not a couple months from now. But I have learned that any other projects are a compromise, and have less 'return' for the investment of time, and other resources. For instance, the wheelie bar is a compromise. But one that will be needed in addition to the above regardless, in steep conditions. So, I will now try to do the adjustments needed on the WHAMS today, and maybe tomorrow. Then I will drag Aaron up here and get started tearing it down and cleaning it up. Then working toward stretching, lowering and widening it. I am getting kind of chibbered about that, already. One last... I have to say. Compared to the craftsman BEAST, the White WHAMS has become a real beauty!!! I hope the Ariens AARON becomes even better. (Haven't thought of any good acronyms for AARON yet, so the name is subject to change. LOL) | |

|   | | LAWN MOWER MUDDER

Established Member

2014 Build-Off Top 3 Winner

2014 Build-Off Top 3 Winner

Age : 23

Join date : 2013-04-08

Points : 5206

Posts : 913

Location : Central Pa

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 4:12 pm July 28th 2014, 4:12 pm | |

| - Anghor wrote:

- ME! wrote:

Honestly for your case a hydro would work better than a gear drive. Gear drive systems can be jerky when letting out the clutch. A hydro on the other hand will be smooth (usually) when you move the pedal or the hand control lever. Most cases the hydro will also return to neutral when you let off the speed control lever/ pedal. That way if you were to fall off it would stop instead of keep going like a gear drive with a standard clutch.

Also about the hydro turning really hard. Most hydro-static trannys have a dump valve. You have to pull the dump valve to push or pull the machine manually. That is probably why it is turning really hard.

LMM, first I have got to say that you and Redline both impress the heck out of me for having such knowledge and understanding at your ages! It's one thing to be able to just repeat what you have heard from others. But much better, you guys actually understand the "why" of things. That line in my sig is pretty much referring to people like you guys. I impress alot of people with my knowledge of trannys, motors, and LT's in general. I do alot of research about the stuff that I talk about.

I'm just glad that there is a place like this, and people like you that I can share the knowledge with! | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 10:32 pm July 28th 2014, 10:32 pm | |

| A word of advice... If you put a wheelie bar on your rig. Kind of temporary. If it tests out good, so you decide to go ahead and make it permanent... Before you drill those last holes and put in those last bolts, make sure that you have the correct ground clearance. Well, unless you LIKE doing the same work all over again! LOL DON'T ask me how I know this...  Ok, here is the final assembly of the wheelie bar. The wheels are 4 inches off the ground. And I made it as simple as I could.   And this is the battery rack I made for the front. You'll see that I also decided to remove the long piece of angle iron, and replaced it with a piece of 2x6 lumber.  I also like to make battery hold-downs out of wood, instead of metal. No matter what the metal is coated with, it always seems to eventually corrode, then you have bare metal next to the battery posts. I like using a thick piece of cedar, like this, or a thick piece of teak. They seem to work the best. (I have a piece of teak handrail for the battery hold down in my trooper. LOL) Ok, now I have finished with all the 'projects' I'd planned on doing to this. Tomorrow I am going to experiment with the vari-drive, the clutch, and maybe a different engine pulley size, to see if I can get better clutch, better brakes, and more speed. After that... on, to the Aaron. | |

|   | | redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7480

Posts : 3131

Location : raleigh nc

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 28th 2014, 10:42 pm July 28th 2014, 10:42 pm | |

| Looks nice! I really enjoy the thought process that not only you, but cornshuck do when you make things. Bolting them together and bein able to transfer it over to another tractor is always great! Something i wish i did on some of my mods. Nice work. | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4233

Posts : 337

Location : Woodville Al

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 29th 2014, 7:55 am July 29th 2014, 7:55 am | |

| Thanks red. Figurin out how to bolt on things is part of the challeng i enjoy.

Angchor i have a question. I dont really understand why you did a wheely bar on your mower vs other options seems to me it takes as long to do that as it would have been to stretch the rear end. And in my opinion the wheely bar defeats the purpas of a utility tracter. How do you plan to haul supply or whatever you transport. As for as building a hill climber youv don a great job. But i just questioning its intended purpus. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 29th 2014, 4:30 pm July 29th 2014, 4:30 pm | |

| - CornShuck4CE wrote:

- Angchor i have a question. I dont really understand why you did a wheely bar on your mower vs other options seems to me it takes as long to do that as it would have been to stretch the rear end. And in my opinion the wheely bar defeats the purpas of a utility tracter. How do you plan to haul supply or whatever you transport. As for as building a hill climber youv don a great job. But i just questioning its intended purpus.

I covered that, earlier in this thread. It seemed the cheapest easiest solution. And in fact, it was. I would have had to tear this tractor apart again. Even further than I did before. I would have had to buy hardware that I couldn't afford. A new belt. Etc. This was just a bolt-on that I made from things I already had, or could easily afford to buy. And it solved the problem. When all was said and done, I arrived at basically the same question as you. Why didn't I just commit to stretching it, way back when I started? The answer is that at that point at least... it seemed like a good idea but it also seemed like way more work than it would be worth. With some experience under my belt now, I now know that it is definitely worth the work, and I'll be doing it to the Aaron. But with this one, once I had the experience and figured out that I should have stretched it, I NEEDED the tractor to be useful... and I mean, yesterday! I couldn't take the time to tear it down and stretch it. I had to get it done fast. So the wheelie bar became the solution of choice on this one. And you are correct about the wheelie bar not being a good thing on a utility tractor. But for now, I need this tractor strictly for the ATV trail, and carrying supplies. (The wheelie bar also works as a rack. I'll have a pic later today.) I'll do some adjustments to this one today, then I'll move on to the Aaron. THAT one is going to be built for utility. (If it's not too flimsy. And if the hydro actually works.) I may stretch the Aaron. At this time it looks like the best candidate for that anyway. But it also looks the flimsiest built, so I may not try to stretch it. I also may come back to the WHAMS later, (Once I have another working tractor.) and stretch it. Who knows what the future holds! LOL I do know I'll keep building until I finally come up with a tractor that does everything I want it to, and does so, safely. That DOES mean eventually one will be stretched! | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4233

Posts : 337

Location : Woodville Al

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 29th 2014, 6:52 pm July 29th 2014, 6:52 pm | |

| Then why dont you get a murray and be finished | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 29th 2014, 8:16 pm July 29th 2014, 8:16 pm | |

| - CornShuck4CE wrote:

- Then why dont you get a murray and be finished

Huh? Where's the fun in just buying something already made up? Besides if I had been able to afford to buy something 5 months ago, when all this started... I would have bought an ATV. And then I would have missed all this fun!    ~~~~~~~ The promised pic of the wheeliebar working as a rack:  Between the red rack I have bolted to the hood, and the crate I can strap to the wheelie bar, I can carry a week's groceries with EASE! ~~~~~ Before doing any adjustments to the clutch and all, today, I decided to go back to the FNR shifter. It was starting to not stick in forward, yesterday. So I decided to do some more work, there. I slotted out the plastic bezel some, so that the shifter could travel farther, in either direction. Then Laid it on the fender, and marked through it to show where I should grind. Then ground the fender some on both ends of the shifting pattern. Then bolted the bezel back in place. Then added a bungee cord to add some tension to hold the shifter tightly into whatever position I put it into. Here is the way it was, after I ground the fender and lust left the bezel off.  Here it is with the fender ground out some more. The bezel slot enlarged. Bolted in place. And the bungee added.  The bonuses are that now I have a positive stop for neutral. And the shifter stays stuck solidly in all three positions. Gotta eat something and get back to work or I'll lose the rest of the workday. | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4233

Posts : 337

Location : Woodville Al

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 29th 2014, 11:16 pm July 29th 2014, 11:16 pm | |

| What i ment was get a murray. (Sarcasticly. There the best. ) haha. I really like the base frame on a murray easy to work on and build lots of options. Get a cheap one blown motor or something and try it. I built a murray and a craftsman at about the same time and thats when i noteced the rear axel on da murray is just a lil further back. Andi think a murray is a lil longer. My murray could go up stuff that the craftsman would flip or almost flip on. Thats why i say that. An if i dont make since sorry. Im just an ol country boy who cant spell or know how to word stuff not very good with computer junk. Mor comfortable with a wrinch in my hand. | |

|   | | Angchor

Member

Age : 67

Join date : 2014-04-14

Points : 4416

Posts : 491

Location : Index, Washington

|  Subject: Re: W.H.A.M.S. Subject: Re: W.H.A.M.S.  July 30th 2014, 12:57 am July 30th 2014, 12:57 am | |

| - CornShuck4CE wrote:

- What i ment was get a murray. (Sarcasticly. There the best. ) haha. I really like the base frame on a murray easy to work on and build lots of options. Get a cheap one blown motor or something and try it. I built a murray and a craftsman at about the same time and thats when i noteced the rear axel on da murray is just a lil further back. Andi think a murray is a lil longer. My murray could go up stuff that the craftsman would flip or almost flip on. Thats why i say that. An if i dont make since sorry. Im just an ol country boy who cant spell or know how to word stuff not very good with computer junk. Mor comfortable with a wrinch in my hand.

Good thinking! Excellent idea! Start with a good frame and build from there. I am really liking the frame on the ariens, and not liking it at the same time. I like that it is lower in the 'saddle area', (between the seat and the dashboard.), than the other two tractor frames. And the way the front axle is put on actually looks pretty solid. As well as there being plenty of beef up there for a good bumper and possibly battery mount, etc. Still, the frame is kind of strangely shaped. And looks thin. But I'll get to that in another thread. ~~~~~~~ I tried the clutch adjustment. If you look at the pic, the red line is the linkage going from the clutch pedal to the vari-drive pulley. The green is a sort of knob that that rod threads through. Remove the cotter pin on the right, pull the rod off the pulley, then you can thread the rod through the green part. Move the rod to the left and the clutch pedal engages the pulley sooner. Move it to the right, and you have to push the pedal farther before the clutch engages.  Soooo, I moved the rod to the left. Good news is that I now have brakes. And the clutch engages sooner. No more pushing the pedal farther than I can reach. Bad news is that the clutch pedal now comes a lot farther backward. And the tractor is a lot slower. Gonna have to revise the names of those seven speeds. 7. I'm tired. 6. I sprained my ankle. 5. Someone tied my shoelaces together. 4. I swear, that turtle must be on speed. 3. Paint dries faster. 2. Tectonic plates are speed demons in comparison. 1. Backward. Tomorrow I will pull the ariens up here and start stripping it. Then I will start a new thread. | |

|   | | Sponsored content

| |   | | | | W.H.A.M.S. |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 32 users online :: 0 Registered, 0 Hidden and 32 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|