|

| | Craftsman Lt2000 Project |  |

|

+20Ariens YT11 jamcco ZSmachines mr.modified 98Murray Jerbear0612 Ozzy's Creations 1997 Murray CornShuck4CE countryboy12894 craftsmancole Angchor tanis Creepycrawler TheRainbowBoxer camomanusa LAWN MOWER MUDDER redlinemotorsportts richie thomas willis923 24 posters | |

| Author | Message |

|---|

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Join date : 2013-07-02

Posts : 731

| |   | | Ariens YT11

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

2015 Build-Off Entrant

2015 Build-Off Entrant

Age : 27

Join date : 2012-10-31

Points : 5167

Posts : 745

Location : The Wyo-Braska Panhandle

| |   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  August 17th 2014, 10:37 pm August 17th 2014, 10:37 pm | |

| Thanks, i'll try to get a write up made soon, I'll post it under the how to section when it's done | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4239

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  August 18th 2014, 8:01 am August 18th 2014, 8:01 am | |

| Looks good like the muffler. My experience with that discharge location is your gonna get soaked in deep water. I dont know how well you can tell but im getting soaked in this pix im actually bent down tryin to deflect the water explosion from the muffler with my hand. Wasent many days there after changed the exaust to come out the back.  But it does sound good. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 11th 2014, 7:42 pm September 11th 2014, 7:42 pm | |

| shocks are fixed, but it turns out the front end is going to have to be done over... turns out i didn't build it heavy duty enough to partner it up with the drum brakes... so I'm going to have to redo the 4 link mounts that are on the axle. I also need to lower the panhard bar down an inch, it keeps snapping welds because it is at a too high of an angle | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4239

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 11th 2014, 8:39 pm September 11th 2014, 8:39 pm | |

| If you check out the place i got all my parts from for the link bars is cheap. Thay also have aluminum link bar. That are cheap. Thats what im going to do on the rear of mine. Thats what im about to start | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 11th 2014, 8:46 pm September 11th 2014, 8:46 pm | |

| yah, i guess the current system should be considered a prototype, it works, it just isn't what it could be. I will probably cut the current mounts off the axle, make some for the frame, and redo the panhard. Can't promise that I get to this anytime soon, school tends to spend a lot more time than i thought it would. Looking forward to see what you do with the rear of your tractor, I bet that will be awesome. | |

|   | | CornShuck4CE

Member

Age : 35

Join date : 2014-04-07

Points : 4239

Posts : 337

Location : Woodville Al

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 12th 2014, 12:18 am September 12th 2014, 12:18 am | |

| O yea gonna be changin alot of things. Not really gonna be a mudd mowet anymore. Gonna be something more adjile an fun. Probly do a youtube update and go over what i plan on doin. O yea that website is. racingrodends.com | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 25th 2014, 7:09 pm September 25th 2014, 7:09 pm | |

| went for a quick ride today, mower is running nice, im thinking about throwing some turfs on the back to do donuts and burnouts  someday ill get to that but for now pics for viewing pleasure   sunset was pretty awesome, definetely not summer anymore, that's for sure | |

|   | | LAWN MOWER MUDDER

Established Member

2014 Build-Off Top 3 Winner

2014 Build-Off Top 3 Winner

Age : 23

Join date : 2013-04-08

Points : 5212

Posts : 913

Location : Central Pa

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 25th 2014, 11:37 pm September 25th 2014, 11:37 pm | |

| Make sure you use small ones like 18s so you have tons of low end power and torque. When doing burnouts out want torque not speed so ya gotta use da smaller tires. That is what I do anyways. When I first put the doclocker in my 930 I only had 16s on the back. That thing would do like high speed spins and drifts like crazy even on fairly dry grass. The smaller tires also help lower the center of gravity which you want when drifting and doing donuts. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 28th 2014, 6:16 pm September 28th 2014, 6:16 pm | |

| - LAWN MOWER MUDDER wrote:

- Make sure you use small ones like 18s so you have tons of low end power and torque. When doing burnouts out want torque not speed so ya gotta use da smaller tires. That is what I do anyways. When I first put the doclocker in my 930 I only had 16s on the back. That thing would do like high speed spins and drifts like crazy even on fairly dry grass. The smaller tires also help lower the center of gravity which you want when drifting and doing donuts.

thanks for the tips, my plans are throwing the stock 20 inch turfs onto the back(all i have) and then wait till the grass is wet try it, if i get nothing from it, eh it wont work... this just the kind of thing i do when im bored anyways. winter is always fun though, this thing did donuts without the locker so im looking forward to that... but hey "its not fun unless you break something"... or is it???   | |

|   | | LAWN MOWER MUDDER

Established Member

2014 Build-Off Top 3 Winner

2014 Build-Off Top 3 Winner

Age : 23

Join date : 2013-04-08

Points : 5212

Posts : 913

Location : Central Pa

| |   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  September 28th 2014, 9:22 pm September 28th 2014, 9:22 pm | |

| very true, the 4-link helps on corners, unlike the stock axle setup, this doesn't "dump" it's weight onto one wheel. the 4 link allows the tractor to corner more flat, my latest problem has been understeer around corners, due to too much traction coming from the 22 inch atv tires in the back, i figure that once i through the stock tires on the back, i will get a little oversteer action. that is if conditions are good and the tractor decides to work properly...  \ back when i had the tractor in it's "beginning stage" i had messed around with the front end to make it flex. This was REALLY good for crawling, but it wouldn't get around a corner if it's life depended on it. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 14th 2014, 6:37 pm October 14th 2014, 6:37 pm | |

|  here yah go, the last picture of the 4 link in this stage. Upgrading the 4 link to a panhardless, triangulated 4 link design. The mounts are all getting replaced, and the frame is getting reinforced. but for now heres some pictures of the tear down.  full articulation minus shocks. hoping to get more after this endeavor is over  heres the full exhaust system, probably going to have to be cut up some  my modded front axle, reinforced tie rod, drum brakes, old 4 link mounts. this is going to see some big changes as well well thats it so far. more pictures to come tomorrow. looking for opinions on the 4 link. should i redo what i currently have, should i go triangulate, or do a 3 link.... the frame is going to get plated. right now it looks like a mountain road  | |

|   | | redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7486

Posts : 3131

Location : raleigh nc

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 14th 2014, 8:54 pm October 14th 2014, 8:54 pm | |

| I'm doing mono link with pan hard on mine. Like a 1" heim with mis alignment spacers. Should be able to flex off a 12"+ rock with all 4 on the ground. And using atv could and custom buckets. Maybe some shocks. Limit straps. Look up lawn crawler on YouTube by rarbaugh07 he explains it. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 14th 2014, 9:14 pm October 14th 2014, 9:14 pm | |

| - redlinemotorsportts wrote:

- I'm doing mono link with pan hard on mine. Like a 1" heim with mis alignment spacers. Should be able to flex off a 12"+ rock with all 4 on the ground. And using atv could and custom buckets. Maybe some shocks. Limit straps. Look up lawn crawler on YouTube by rarbaugh07 he explains it.

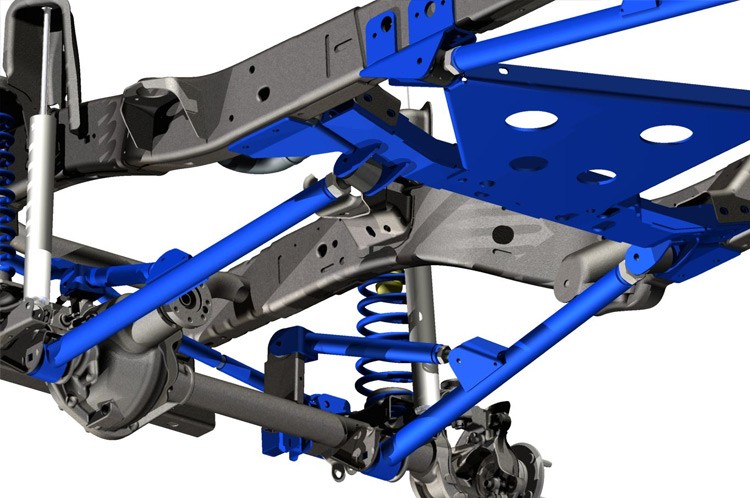

thanks red, This current setup worked but it was tacky, could of been done way better here's some concept pics for what I am thinking of doing.   going to go shock hoops this time, i dont like how the current setup looks, it was thrown together in a course of a week and needs major improvements, all the mounts needed to be made of stronger metal, BIG TIME. I am going to have to change the postion of everything, i think as is my maximum flex is limited by too many factors. i dont want to change how it sits though, i like the stance as is. **REPAIRS SOON TO COME**

Last edited by jamcco on October 14th 2014, 9:16 pm; edited 1 time in total (Reason for editing : I couldn't type) | |

|   | | redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7486

Posts : 3131

Location : raleigh nc

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 14th 2014, 9:36 pm October 14th 2014, 9:36 pm | |

| Yea, there is improvement. I was thinking of triangulated but I wasn't sure how it would hook up underneath and turning with the links and large tires. A bunch of ways, wishbone, 4 link, 3 link, 5 link, ifs, leafs, ect. I love playing with suspensions though. Can't wait to see how this comes out. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 18th 2014, 6:24 pm October 18th 2014, 6:24 pm | |

| ok so I have been working on this all day. Turns out my plans changed AGAIN. I'm not doing the triangulated 4 link like I had said, there just isnt enough room for anything. I'm doing a "Long Arm" style suspension, much like they do on jeeps.  I dont know if anyone recognizes this, but these are the plates that hold the front axle in on craftsmans. I took these, welded them together, and created a drop mount bracket to hook my long arms too.  the two plates welded up, the frame side bolts right up to the chassis, while the bottom half allows me to have 2 bolt holes to choose from when it comes to mounting the arms up  drop mount bolted up. I ended up bolting this right about in the middle of the tractor, this allows me to have more leverage on the long arms    The long arms turned out like this, i welded studs in the ends so that my heims (temporarily ball joints) can be adjusted to push the axle forward and back. They are slightly triangluated, so I might be able to get away without having a panhard, I dont know at the moment. I still need to make mounts in order to bolt this to the axle  U bolts may be my "new" shock hoops, they'll probably need some braces    The tierod was in the way of the long arms, so I ended up modding the spindles by swapping the piece of the metal that attatches to the steering arm and welding it to the opposite spindle. So this was as far as i got today, all thats left is to -weld Ubolts to frame, brace, and weld washers for shock mounts -weld up some mounts to bolt the axle to the long arms -paint -flex -donuts | |

|   | | redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7486

Posts : 3131

Location : raleigh nc

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 18th 2014, 6:42 pm October 18th 2014, 6:42 pm | |

| Wont there be no flex With that? looks like a swing arm up front if you welded the triangulated tubes to the axle. looks like a bunch of travel though! might be time for some longer travel shocks...  | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 18th 2014, 7:14 pm October 18th 2014, 7:14 pm | |

| That's what I've been thinking the whole time I've been building this. This is an experiment I guess. If this doesnt work then I'll I'll make new arms. the tubes arent going to be welded to the axle. im going to make one of these two ideas 1. C shaped brakets on the ends of the pipe. then weld a smaller tube on the axle, and run a bolt through it.... I'll try to draw it out on sketchup.......I'm 50% sure that this will still flex like this. The main pivot point is now on the joints on the frame side of the arms. it will still flex, but im not sure by how much 2. I could weld some joints to the end of the pipes and see how that flexes. I am probably wrong on all of this but that's what they invented sawzalls for  Longer shocks are something I want right now. The plan is to notch the frame so the axle will have more room before it bumps, then box the frame, and call it good. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 19th 2014, 4:25 pm October 19th 2014, 4:25 pm | |

| got it able to roll again. far from done unfortuantely. I messed up in about 100 different places when it came to welding the mounts for the "long arms". My geometery must of gotten off while welding. any who this is probably a 5 minute fix if done right. But here it is, in all her glory as of today     In total I have 17 inches of wood and tire under the front wheel. remember this only the bars and no shocks, so i may not get this much flex out of it, but that aside, this is possible if I get the right parts. also notice the frame flex, thats going to have to be fixed....input on the build is always apprecitated  Getting back to you red, I didnt think this would flex when i bolted things up, it was acting just like a swing arm. but i guess i ended up getting more movement out of those two rear joints than i thought. | |

|   | | redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7486

Posts : 3131

Location : raleigh nc

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 19th 2014, 8:58 pm October 19th 2014, 8:58 pm | |

| Confused, it flexes like that all bolted up? Because it shouldn't, least i think it shouldn't. err, im confused. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 19th 2014, 9:29 pm October 19th 2014, 9:29 pm | |

| - redlinemotorsportts wrote:

- Confused, it flexes like that all bolted up? Because it shouldn't, least i think it shouldn't. err, im confused.

to be 100% honest, it doesnt make sense to me either. the links arent bending, mounts are still straight....I keep thinking somethings not right, I'll have to take a look at it tm and see how thing button up, (it is still posing in front of my house, im seeing if anything settles funny. I think i will still need a panhard bar. The only way it could be flexing this nicely is if the ball joints on the bar are pivoting much more than I expected them | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 23rd 2014, 6:58 pm October 23rd 2014, 6:58 pm | |

|     OK so RESEARCH RESEARCH RESEARCH! the idea of this suspension is to based off of jeep TJ,XJ, CJ, etc long arm suspension kits, grant it, my arms dont have the adjustable bars on them, but the idea is there. the flex comes from the joints allowing the axle to tilt and move up and down. the reason why i chose this design is because it isnt about up travel, which i dont have alot of, this design is meant to just drop. an idea i am having right now is using my shocks has bumpstops, meaning they just sit on the axle instead of being physically bolted to it. then i could order car hood shocks to give me some suspension. the atv shocks will act as coils AND bumpstops. The hood shocks will act like fox shocks, that DROP into obstacles instead of lifting the wheel up.Then I could build my own limit straps. Before i go this far, im going to make shock mounts, bolt everything up, and see how it performs. If she flexes fine then I wont have to do what i mentioned above, but I still think that the previous idea will be much better and be very cool. Suspension is very cool, but hey it's leaving me in suspense. Tips would be more than helpful. | |

|   | | redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7486

Posts : 3131

Location : raleigh nc

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 24th 2014, 4:38 pm October 24th 2014, 4:38 pm | |

| I think its only good for a slow crawler for strict droop style suspension. Anything at trail speed might just feel bad. but id try it,maybe some rubber bumps to soak up a little vibration. | |

|   | | jamcco

Member

Age : 25

Join date : 2014-01-04

Points : 4219

Posts : 226

Location : New Hampshire

|  Subject: Re: Craftsman Lt2000 Project Subject: Re: Craftsman Lt2000 Project  October 27th 2014, 6:31 pm October 27th 2014, 6:31 pm | |

| the idea is to throw the shocks on, and then see if it still flexes, I have no idea if these will still work with droop style suspension. i did finish up the arms, so now im going to have to spend some time on hooking up shocks, or something of that sort. That is going to be bit of a project, I honestly think I'm going to have to buy new shocks for this, because I doubt these atv shocks will still work in this application. I think this will definetly need bump stops seeing that the short ride i went on was very noisy and rough. But for now, here's some shockless beauty    sweet RTI ramp am i right   sorry for the picture quality, this getting dark early stuff is a pain | |

|   | | Sponsored content

| |   | | | | Craftsman Lt2000 Project |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 26 users online :: 0 Registered, 0 Hidden and 26 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|