| | “Beast” - Craftsman II Utility Build |  |

|

+10RichieRichOverdrive MightyRaze AllisKidD21 redzz02 Crazy_Carl Rerun Murraymountain CraftsmanQuad19 TheCollector WayneTrain2000 14 posters |

|

| Author | Message |

|---|

WayneTrain2000

Member

Join date : 2019-11-16

Posts : 80

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 20th 2020, 2:35 pm January 20th 2020, 2:35 pm | |

| What’s the biggest pulley I can run on front? Hopefully at least 6. Being that the smallest pulley I could make work on the back was 6, I’m hoping to at least get 1:1 ratio if not higher. | |

|

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4432

Posts : 2178

Location : North Carolina

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 21st 2020, 3:56 pm January 21st 2020, 3:56 pm | |

| 6" should be no problem. I think creepycrawly runs a 7" or something on the front of his wheel horse. As long as you have some good keepers and a clutch with some decent movement. Should be ok. I personally hate figuring that stuff out, but once you get it figured out it'll be ok.

By the way, nice garage floor. Looks like a formula one shop in there. | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 5019

Posts : 731

Location : Logan Ohio

| |

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 21st 2020, 9:11 pm January 21st 2020, 9:11 pm | |

| Are those tractors similar frame styles to mine? I don’t know what kinda clearance these stamped frames have up there... I’ll do some measuring when I get a chance. | |

|

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4432

Posts : 2178

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 22nd 2020, 10:31 am January 22nd 2020, 10:31 am | |

| No I don't think they are. The AMF might be similar, but definitely not the Wheel Horse. You might be able to fit a 7" on it. You'll need to remove the tie rod to get it on though... I just barely could get the 6 on without taking the tie rod off. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 27th 2020, 2:58 pm January 27th 2020, 2:58 pm | |

| I ordered bushings and they came in today, they are the wrong size. They just flop around in the hole. Could someone help me find some of these bushings for this tractor? I’m having a tough time finding them. | |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5037

Posts : 318

Location : Western,PA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 27th 2020, 5:16 pm January 27th 2020, 5:16 pm | |

| So I did a real quick skim of your build and I didn't see anything about bushings your trying to replace.

So what bushing are you replacing and do you have any pics to help me out.

If your talking about bronze bushing or plastic bushings I deal with McMaster carr on those. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

| |

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5037

Posts : 318

Location : Western,PA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 28th 2020, 6:10 am January 28th 2020, 6:10 am | |

| Judging by the last pic they have knobs molded into them so they don't spin in the housing. That will be hard to find in an aftermarket replacement, but to me that's no big deal if there not there. Without knowing your exact sizes it's going to be hard to tell you what ones to get. Most spindles I come across 3/4 dia. But I've seen 5/8 and 1in too. Judging by the pic too it looks like the bushing wall thickness is 1/16th which would add 1/8in difference between the spindle hole size and the housing hole size but I'd still measure that to be sure.

I'd head over to McMaster carr look for bearing category and there is a thing on the side of the screen if you know your sizes that will show you what all different styles they offer to fit your needs. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

| |

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  February 2nd 2020, 3:26 pm February 2nd 2020, 3:26 pm | |

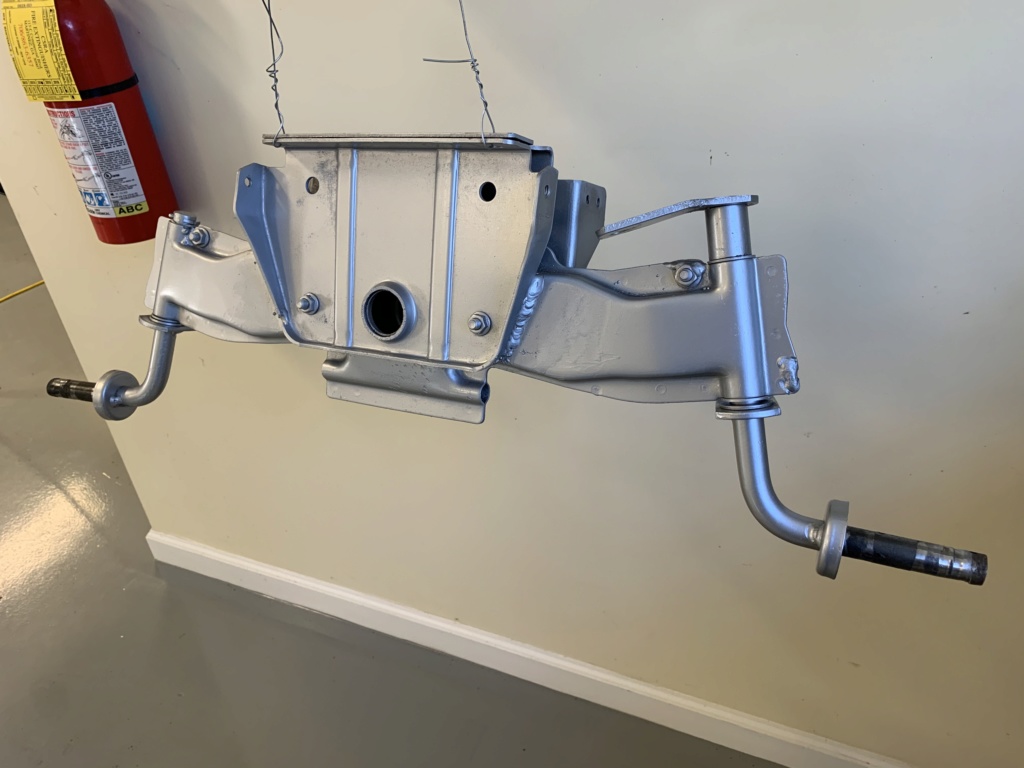

| Alright folks, axle is back together and painted. Today I pulled the front pulley and confirmed the output shaft size, about to order a 6” pulley from Phoenix. All is going well!   | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  February 5th 2020, 5:05 pm February 5th 2020, 5:05 pm | |

| Finally up and running!

Pulley went on without a problem, the belt I have is a little too tight so it’s grabbing regardless of clutch pushed in or not. It also has some weird jerking going on, most noticed in top gear. It feels like the belt is binding on something.

Front axle is way better, handling so much better and just feels a lot more safe and solid.

It definitely runs faster than before, but not terribly fast. I haven’t checked the actual speed yet. Wish I could get a little more speed out of it but this pulley setup seems to be about is large as I can go in front and as small as I can in rear.

Nonetheless, I’m happy to be making progress on it.

Pics don’t want to upload as usual, I’ll get some out when possible. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  February 7th 2020, 10:13 pm February 7th 2020, 10:13 pm | |

| Finally getting somewhere with it. Put on a belt an inch bigger, clutch now works as it should but it was throwing belt off every time I pushed the clutch in. Removed stock belt retainers, bent them over and welded on some extra round stock to them. They worked perfect. But still the belt was being thrown off front pulley, so I made some for up there too. Now works perfect. The belt is a little more slack than I’d like with clutch in but it works fine. I haven’t had it come off once since installation of retainers. I got it up to 13mph on GPS, and probably could’ve gotten more out of it but the brake barely works. I guess that’s next. Finally getting satisfied with this thing. Thanks for all the help and suggestions thus far!    | |

|

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4432

Posts : 2178

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  February 7th 2020, 10:48 pm February 7th 2020, 10:48 pm | |

| Nice! I tried to put belt retainers on my stamped frame, but it was a fail. Just made the belt harder to put back on. Glad to see you got though! | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  February 7th 2020, 10:50 pm February 7th 2020, 10:50 pm | |

| Yeah, changing belts will definitely suck. I already have to remove clutch idler, unbolt shifter link and remove the shifter support bracket to remove belt, and all of those retainers will definitely have to be loosened/removed as well now. But I consider it worth it, just to have a belt that stays on. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  April 2nd 2020, 1:51 pm April 2nd 2020, 1:51 pm | |

| Well folks, haven’t been on this thread in a while. She’s still alive and kickin’. Been using it a little bit and making a few improvements and repairs here and there. It burns oil pretty good when it’s cold but it’s a flathead, keeps on chugging and I just keep feeding it oil. Finally shortened my throttle cable and ran it through the side panel to make it look nicer and work smoother. Man is it a pain to modify these linkage cables!!! I ended up just filling the cutout on the bike handle (that the ball on end of linkage would normally slip into) with epoxy and jamming the end of the cable in there. Seems to hold for now. Also got the kill switch working, when I redid the wiring to remove safety sensors, I accidentally cut the kill wire clean off the plug on key switch. Been pulling spark plug boot off to kill it in the meantime, but finally got that working again. The Coronavirus situation kinda has me stuck at home, so I’m looking for new things to do on the machines. The one issue I need to address is the jerking in 6th. It feels like belt slip to me. But only happens in 6th. I don’t think I could add another idler pulley to tighten, because even now the belt doesn’t always completely disengage with the clutch in. Could a pulley be to blame?    | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7221

Posts : 4020

Location : Lewisburg, KY

| |

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4432

Posts : 2178

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  April 2nd 2020, 5:52 pm April 2nd 2020, 5:52 pm | |

| Yeah it might be. I wouldn't bother checking just yet. There's other ways to tell. If it kinda seems like it could be catching on something a little bit when you shift, that's a red light. Grinding gears when shifting or when under pressure is another indicator. And especially, if you lose that gear, or other gears start with that problem too, that says it all. And you'll probably get all of these symptoms if they're gone. Those are the symptoms I got when mine went. It was progressive though. Started when second started jerking, then 2nd went completely, then 3rd gear started grinding, then it started jerking, and then I only had 1st and reverse, and then I lost all gears. All happened within an hour of driving it. These are the shift keys out of my MST:   That's what they should not look like. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  April 2nd 2020, 8:10 pm April 2nd 2020, 8:10 pm | |

| I haven’t bothered to open up that transaxle because I’m fairly sure it’s grease-packed. I know that’s gonna be a mess. No grinding in any of the gears, everything runs pretty smooth. Just 6th for whatever reason. I might just go ahead and lock it, give me a reason to open it up! | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  April 4th 2020, 1:28 am April 4th 2020, 1:28 am | |

| Another thing I just remembered that may point to a shift key issue, is sometimes when shifting out of a forward gear into reverse, it doesn’t want to shift. I have to force the shifter pretty hard, and when it finally goes into reverse it makes a loud pop. But as far as running thru the forward gears with the SOTF, it shifts nice and smooth.

Should I just dive in and investigate shift keys? | |

|

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4432

Posts : 2178

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  April 4th 2020, 10:02 am April 4th 2020, 10:02 am | |

| Eh, that sounds more like the shifter being out of adjustment. I don't remember if they're adjustable on the stamped frames, but that's what happens on a widebody when the shifter is out of adjustment. Now if an adjustment doesn't fix the problem, then it could be shift keys.

But until you get more problems trans related, I would just leave it alone. | |

|

| |

WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1930

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  April 20th 2020, 9:15 pm April 20th 2020, 9:15 pm | |

| Well folks, I was pulling the beast into the shop today, and there’s a pretty good ledge where the concrete begins that I had to roll over to get in. I had it in 1st, but back tires weren’t gripping. So, I go to shift into reverse, and the shifter won’t move. Gave it a little extra pressure, because normally it will pop out of gear and shift when this happens. But instead of a pop, I got a soft sort of “metal bending” feeling in the shifter. It’s now stuck in 1st, shifter moves the entire range and no linkage is damaged, it even moves the shifter on the transaxle, but it’s not shifting.

I haven’t investigated yet, I will dig in tomorrow. Guess maybe those shift keys were going after all? | |

|

| |

Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4432

Posts : 2178

Location : North Carolina

| |

| |

tharvey

New Member

Join date : 2020-05-05

Points : 1679

Posts : 15

| |

| |

tharvey

New Member

Join date : 2020-05-05

Points : 1679

Posts : 15

| |

| |

Sponsored content

| |

| |

| | “Beast” - Craftsman II Utility Build |  |

|