|

| | “Beast” - Craftsman II Utility Build |  |

|

+10RichieRichOverdrive MightyRaze AllisKidD21 redzz02 Crazy_Carl Rerun Murraymountain CraftsmanQuad19 TheCollector WayneTrain2000 14 posters | |

| Author | Message |

|---|

WayneTrain2000

Member

Join date : 2019-11-16

Posts : 80

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 10:36 am December 18th 2019, 10:36 am | |

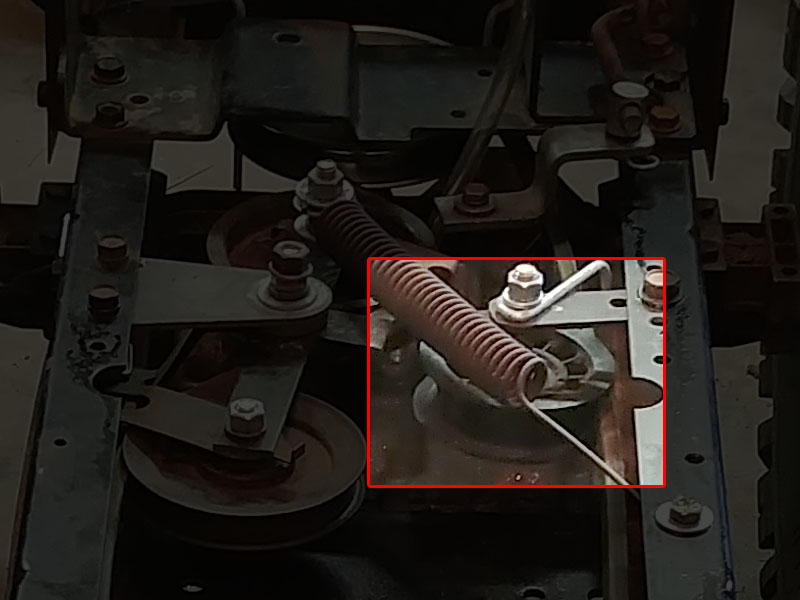

| Alright, I’m just stumped at this point. I’ve tried just about every belt size from 80 to 87. I’ve been to tractor supply to exchange belts so many times they probably know me by my name. It’s either so tight that I can’t slip it over the pulley, or it’s so loose that the clutch comes back and completely collapses on the belt. I think at this point I’m gonna have to do away with this clutch system and build a new one in the middle/front of the tractor. If anyone could give me some really simple designs I’m ready to run with it. I’d like to keep materials that I have to buy at a minimum.  Swapped to a 4” pulley, hoping it would improve belt fitment.  Example of how the clutch pinches the belt between shifting link and belt keeper. I thought that if I got a short enough belt this wouldn’t happen, but a ‘short enough’ belt wouldn’t even go on the pulleys.

Last edited by WayneTrain2000 on December 18th 2019, 5:43 pm; edited 1 time in total | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8588

Posts : 5190

Location : Ontario Canada

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 10:41 am December 18th 2019, 10:41 am | |

| Should be 1".  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | Crazy_Carl

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 35

Join date : 2017-10-30

Points : 5334

Posts : 2561

Location : Rochester, New York

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 5:35 pm December 18th 2019, 5:35 pm | |

| Should have a 1/4" keyway too. You'll need a piece of keystock the same length as the keyway in the hub to do the pulley swap too. | |

|   | | MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15677

Posts : 10988

Location : Oklahoma

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 7:47 pm December 18th 2019, 7:47 pm | |

| May need to fab you an idler from the other side to pull the belt off your shifter. Here is an example of mine below. The highlighted pulley in the picture below is used on my tractor to keep it off the shifter.  It can even be made to be an adjustment pulley. | |

|   | | redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 30

Join date : 2010-05-12

Points : 6377

Posts : 899

Location : PA pittsburgh and pymatuning

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 18th 2019, 9:12 pm December 18th 2019, 9:12 pm | |

| Your belt running into the shifting rod is another reason why 95% of us suggest not going so small on the transaxle pulley, it may be easier for you to just put a larger pulley in the rear and bump that front one up bigger | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 19th 2019, 2:08 pm December 19th 2019, 2:08 pm | |

| Got the intake back today, put some high heat JB weld putty on the areas that weren’t welded. Seems to be sealed well enough. I had him weld it with the bolt in the flange as you can see, because the 90 in the tube wouldn’t let me insert it any other way. That’s the main reason that area couldn’t be welded. Will install and update tomorrow.   | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 7:11 pm December 20th 2019, 7:11 pm | |

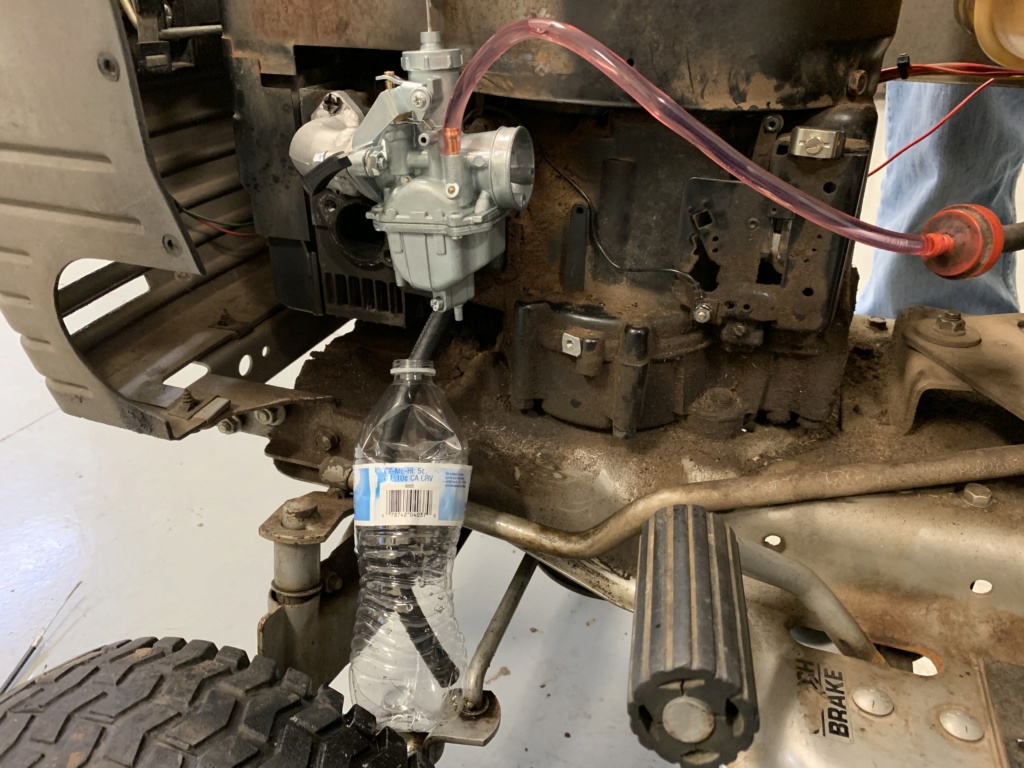

| As usual, this machine has me really frustrated and confused. Last night, we installed carb for a test run. Turned choke on, turned key and it started. It ran pretty high rpm and blew smoke like crazy. We couldn’t get motor to slow down so we decided to shut it down. Key off, motor kept running. Apparently I’ve accidentally removed the ground wire for coil. Had to pull the spark plug boot off, which felt awesome as you could imagine. The boot was off the plug completely, sitting 1/4” away from it and still arcing to the plug. Now that we had all that sorted, I put the carb back on and gave it some fuel. We are now having trouble to keep this thing running for more than 5 seconds. It will only even think about firing at full choke, and when it does it’s an extremely low idle. If you turn it over with full choke, and slowly just give it a hair of throttle, it will run for a few seconds, and die. We’ve had the mix screw all over the place. Nearly turned all the way out, all the way in, and about everywhere in between. I’ve moved C-clip on needle from the middle slot to the lowest slot, It just will not run.  Hose going into the bottle is for the breather tube. That thing spit oil everywhere when it did run last night. Not letting that happen again.

Last edited by WayneTrain2000 on December 20th 2019, 7:17 pm; edited 1 time in total | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 7:16 pm December 20th 2019, 7:16 pm | |

| Also, apparently there have been several posts made on this thread that I haven’t seen until just now.

I kinda took a break from the belt/pulley situation to try and get the motor sorted out. I guess I’ll swap to a larger rear pulley, larger front pulley and then see what/where idlers need to be made. | |

|   | | redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 30

Join date : 2010-05-12

Points : 6377

Posts : 899

Location : PA pittsburgh and pymatuning

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 8:30 pm December 20th 2019, 8:30 pm | |

| My guess is your intake is the reason for your issues, I bet there is a pin hole letting air in and making your air mixture off | |

|   | | Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4433

Posts : 2178

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 9:22 pm December 20th 2019, 9:22 pm | |

| Also, not sure if you got your high RPM stuff sorted out yet, but your governor is in the wide open position in that pic. Not sure if you pushed that down when it ran the first time. If it goes wide open again, try pushing it down. If the RPMs don't go down, well, you got a problem. | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8588

Posts : 5190

Location : Ontario Canada

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 10:20 pm December 20th 2019, 10:20 pm | |

| - Murraymountain wrote:

- Also, not sure if you got your high RPM stuff sorted out yet, but your governor is in the wide open position in that pic. Not sure if you pushed that down when it ran the first time. If it goes wide open again, try pushing it down. If the RPMs don't go down, well, you got a problem.

Governor's not doing much with that slide carb on there.   "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | Rerun

Member

Join date : 2019-04-19

Points : 2132

Posts : 75

Location : Florida

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 10:23 pm December 20th 2019, 10:23 pm | |

| I would be concerned about the breather hose blowing oil like you mentioned. Usually serious blow by or a blown head gasket causes that to happen. If you get enough blow by pressurizing the crankcase it will run all sorts of crazy. | |

|   | | AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8588

Posts : 5190

Location : Ontario Canada

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 20th 2019, 10:38 pm December 20th 2019, 10:38 pm | |

| If there's an air leak like Sean mentioned it could also be the cause of the high RPM's upon startup.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|   | | Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4433

Posts : 2178

Location : North Carolina

| |   | | RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7223

Posts : 4021

Location : Lewisburg, KY

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 22nd 2019, 12:26 am December 22nd 2019, 12:26 am | |

| Sounds like your intake mating faces warped when you welded it. It didn't exactly look precision ground in the first place. Double up on (or silicone) the gaskets or take it back to whoever welded it and maybe have him hit the faces on a belt sander or something. If that doesn't fix it, check your putty job. Maybe go to silicone instead. Or maybe gas tank putty?

I don't know why your weld guy couldn't have welded that all around. Anyone who's reasonably good with a TIG could weld that up both inside and out. Unless he was using a spoolgun, which then I would understand him not welding it all the way.

Good luck. In my opinion you should just go back to the stock carb, but that's just my K.I.S.S. ideology. | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 22nd 2019, 1:46 am December 22nd 2019, 1:46 am | |

| Well, she’s alive. I sat down with it for probably 30 minutes trying to get the mix screw right (stupid thing is on the INSIDE of carb facing engine), and finally found that sweet spot. There is no intake leak that I am aware of, the flanges are not warped at all, no type of holes in the weld, and my JB weld job turned out fine. It’s now running really nice with an impressively low idle. Just a little black smoke from exhaust when you rev it up that I still need to sort out.

I have a video of it running, but can’t get it uploaded to Google Drive. May try again in a little bit.

The idle this thing can run at is crazy to me. My 17.5 OHV could never even come close. Of course it’s not really practical, but we were able to drop it to the point it almost sounded like it was gonna die, but just kept on going. It also will not run without the air filter installed, and doesn’t particularly like to run without the muffler on. I found this interesting but I’m sure it has to do with the air/fuel mix.

As for the oil coming from breather tube, not a drop of oil has come from it since the one time. I believe excess oil was purged out, as it was probably overfilled. Now, it just gently puffs out air while engine is running, which I presume is what it’s supposed to do.

Anyways, got a throttle set up, welding tube to the floorboard tomorrow to have somewhere to mount a bike brake handle to. Everything engine wise is coming together nicely.

Thanks everyone for the help and suggestions so far. | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 22nd 2019, 7:57 pm December 22nd 2019, 7:57 pm | |

|  Welded the tube to the floor, painted it and got the pedal mounted. Pretty happy with it. Having trouble posting vids of it running, but it runs about as good as I could ask it to. | |

|   | | RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7223

Posts : 4021

Location : Lewisburg, KY

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 22nd 2019, 8:06 pm December 22nd 2019, 8:06 pm | |

| Don't idle it too low for too long. Besides being impractical, less oil gets around at low RPM and might damage your engine. | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

| |   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

| |   | | MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15677

Posts : 10988

Location : Oklahoma

| |   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  December 23rd 2019, 10:48 pm December 23rd 2019, 10:48 pm | |

| Stock 4 on front, 6 on rear. TSC didn’t have a 6” with 1” bore. Soon as I track one down I’ll be installing it on front. I believe 6 is about as big as I can fit up there.

Everything in the front end is extremely wobbly, the spindle on one side is just flopping around in its hole on the axle. Axle itself has a ton of front to back play, steering is really loose. It almost felt sketchy just at 7! Probably gonna weld front axle solid, not sure what I need to do with that spindle. | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 7th 2020, 5:06 pm January 7th 2020, 5:06 pm | |

| Alright folks, decided it’s time to get this axle out from under it and get it welded. I just finished flushing out the inside of the axle, as it was entirely packed with grass and dirt. Getting dark on me now so I’m gonna let these pieces dry tonight and then prep/weld tomorrow. There’s a couple hairline cracks around the axle, and one around the tube that the spindle sits inside of. I actually got a TIG machine for Christmas so I’ll be tigging those cracks up, 7018 stick welding the big stuff. Will post pics once done. | |

|   | | Murraymountain

Veteran Member

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

2022 Build-Off Entrant

2022 Build-Off Entrant

Join date : 2019-02-04

Points : 4433

Posts : 2178

Location : North Carolina

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 20th 2020, 2:10 pm January 20th 2020, 2:10 pm | |

| Nice job on that gas pedal! Looks real professional.

I would completely rebuild the front end if I were you. Those stamped frame front ends are just trash. I'm not gonna rebuild mine because it's just a backup rig, but if you want it built right, the front end probably needs to go.

As for your pulley, I'd just check around online... That's where I get mine. They're about $25 from Phoenix Pulleys. | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 20th 2020, 2:15 pm January 20th 2020, 2:15 pm | |

| - Murraymountain wrote:

- Nice job on that gas pedal! Looks real professional.

I would completely rebuild the front end if I were you. Those stamped frame front ends are just trash. I'm not gonna rebuild mine because it's just a backup rig, but if you want it built right, the front end probably needs to go.

As for your pulley, I'd just check around online... That's where I get mine. They're about $25 from Phoenix Pulleys. Thanks! I’ve kinda been hung up because I accidentally welded the plates backwards on the axle. So I had the spindle with the attachment for steering arm on the wrong side. Said spindle was welded onto the axle, so I had to cut it to swap them. The spindle bushings were destroyed, so I’ve gotta get some before I reassemble. Been working on other projects so it kinda got swept under the rug. I’ll look into the pulley. | |

|   | | WayneTrain2000

Member

Age : 22

Join date : 2019-11-16

Points : 1931

Posts : 80

Location : Augusta, GA

|  Subject: Re: “Beast” - Craftsman II Utility Build Subject: Re: “Beast” - Craftsman II Utility Build  January 20th 2020, 2:35 pm January 20th 2020, 2:35 pm | |

| What’s the biggest pulley I can run on front? Hopefully at least 6. Being that the smallest pulley I could make work on the back was 6, I’m hoping to at least get 1:1 ratio if not higher. | |

|   | | Sponsored content

| |   | | | | “Beast” - Craftsman II Utility Build |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 42 users online :: 0 Registered, 0 Hidden and 42 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|