| | Simplicity Broadmoor R/S Project |  |

|

+17Hillbilly Offroading redzz02 muddstir redlinemotorsportts prancstaman mrshaft696 MightyRaze JohnLidell diddie TheBeal mowerjunkie03 RichieRichOverdrive Mister_Studabaker Creepycrawler AllisKidD21 CraftsmanQuad19 mr.modified 21 posters |

|

| Author | Message |

|---|

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Join date : 2016-04-12

Posts : 2645

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 9th 2020, 6:43 pm January 9th 2020, 6:43 pm | |

| That was the biggest challenge for me. Finding a rack narrow enough with a center input that’s straight. Pretty tough to do really | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 9th 2020, 8:18 pm January 9th 2020, 8:18 pm | |

| My plan is to mount it centered and hooked to both wheels. It's not ideal that the shaft points towards the outside but luckily it's not by a lot. I may end up with 3 universals total. We'll see. I don't want to add a ton of weight with a super heavy steering shaft but small sized universals are available.

I think what I'm going to do is go the risky route of making the front end and frame and then dealing with the issue of going up over the engine. 99% sure that's where I'm gonna run it.

I looked through a lot of different racks but pretty much all of them have that offset to the outside. | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 11th 2020, 6:26 pm January 11th 2020, 6:26 pm | |

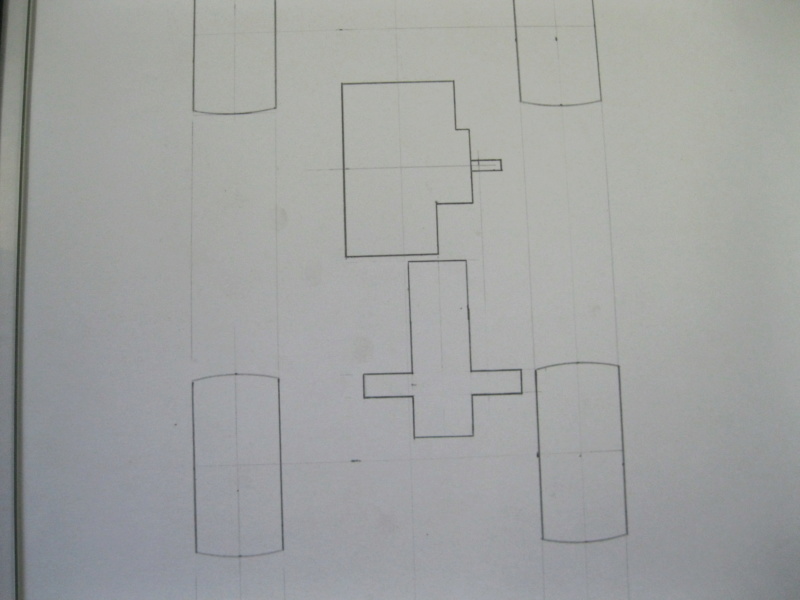

| Started mocking things up today to begin frame construction accoring to my drawing  The frame is going to be a bit odd but it looks like everything will work out ok as far as I can tell  This is a mock up axle I threw together so that I can bolt two wheels at 42" outside width  I think the rack and pinion will need to go forward of the front axle center line and between the upper and lower control arms. I might be able to get away with only two u-joints in the steering shaft.  That's the light weight plastic seat I'll be using. The transmission will probably be about this close to the engine, but there's some room to move things around a couple inches here and there if necessary. I decided to build a naturally aspirated engine and not go the supercharger route for now. One reason is I'm worried about running issues and not being able to tune it in time for the 2020 TTC. Another is I think I will have my hands full getting the steering and suspension done on this build as it is. So I will try to leave room for a supercharger later on, which shouldn't be an issue. I have some spacers ordered for the front spindles to make things fit correctly, should be starting to do some actual welding on the front end soon.  | |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 11th 2020, 9:21 pm January 11th 2020, 9:21 pm | |

| Man I like what I see.

That looks like how I want to run my transaxle on my troy bilt build - if I'd ever get back on it. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15677

Posts : 10988

Location : Oklahoma

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 11th 2020, 11:02 pm January 11th 2020, 11:02 pm | |

| Thanks. And yeah it might go a bit farther forward but I don't know how much space I will have with the suspension. I will have a tiny bit of extra room with the rack and pinion in front instead of in back how I originally planned it.

Center of gravity will be a lot lower than the adventure edition and also, the trans being forward about 6-8" of the rear axle should help too. | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 5020

Posts : 731

Location : Logan Ohio

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 15th 2020, 12:51 am January 15th 2020, 12:51 am | |

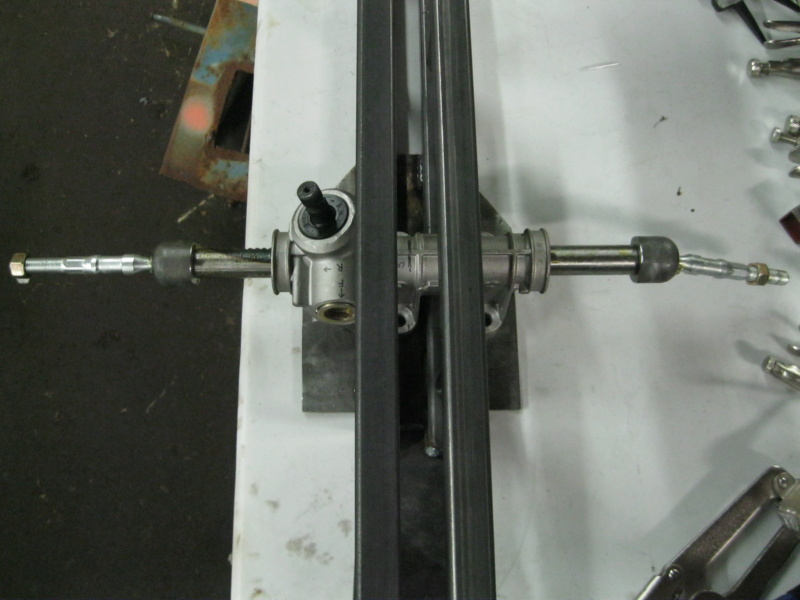

| Thanks. I should have some more pics going soon and some actual fabrication in progress. Tonight I started figuring out the front end. The rack and pinion I bought does fit and could be made to work, but I have a cub cadet steering box that may be a nicer fit. I originally didn't want to use it, but it's a faster ratio than the rack too and might do a better job.

The rack and pinion is about 3.75 turns lock to lock, with the cub cadet box about 2.25ish if I remember right. I figure it won't be so good whipping the wheel like crazy on a short course if you need to also keep yourself on the machine by holding the steering wheel. The cub cadet box is actually a really simple screw setup with a pin. I expected it to be gears.

I need to lock down my plans before working on the frame since I want to incorporate the mounts for the steering in the right place.

Other minor plan alterations: Upper and lower control arms will probably be square tubing instead of round. I will need to make some tight bends and square will be easier to work with. Plus my heim joint weldable inserts fit nice into the square steel I have. I could not find the correct round tubing to make a snug fit. | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 15th 2020, 11:31 pm January 15th 2020, 11:31 pm | |

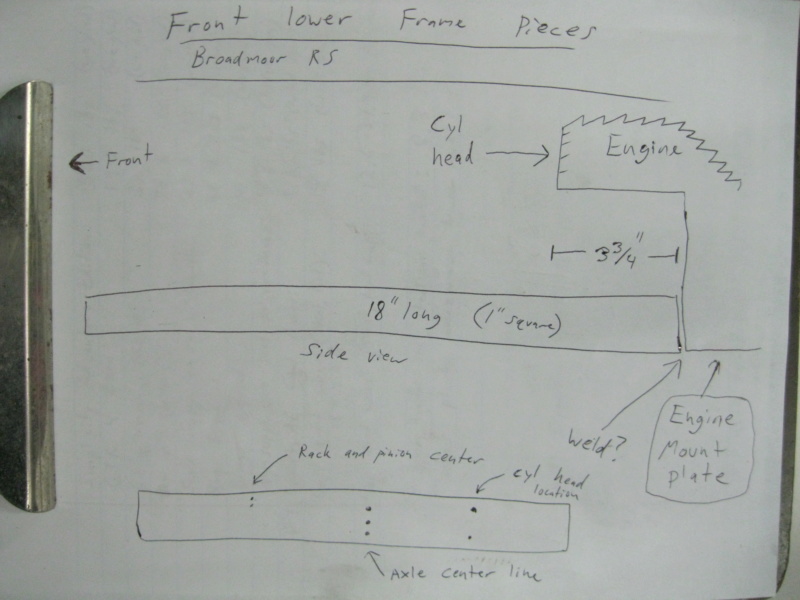

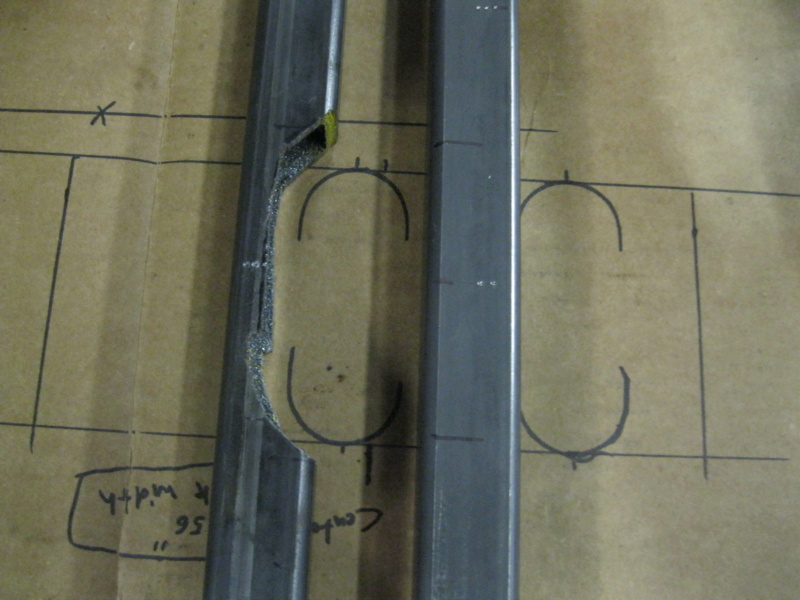

| Think I changed my mind again today so it's probably back to the rack and pinion. But anyway, here's some pics of the cub cadet steering box. I originally thought they were sealed, but not really. Still a very simple and rugged design. A disadvantage for this project is odd mounting angles. The rack unit mounts on a flat surface. Also I would have to modify it quite a bit.  Here's the cover removed. A big bolt/stud is the pivot and a heavy duty pin which engages the screw.  A close up of the screw. The silver boarder is actually a replaceable piece. Like a bushing sort of.  Both of these are 1" box steel. The thin one on the right is 16 gauge. Same as most automotive exhaust pipe. That's what I used for the GTR 4 zero frame. On the left is what I'm using for all the main frame sections of the Broadmoor RS. I think it's called 11 gauge? Probably about twice as thick and much stronger. A little heavier of course. Outside dimensions are about the same, so I can use some of the lighter 16 gauge in some areas for bracing without adding the extra weight.  Finally started on the frame tonight with the first two short pieces cut for the lower part of the forward frame. The lower control arms will bolt to those sections and also the steering rack will mount to it. I plan on tying the front end together with a sort of skid plate angled at about 45 degrees. Ground clearance on this thing will be somewhat less than what most off road tractors end up with, but not by much. Just marked this out to show me where I marked things in case I can't remember when I get back to it again. The dot's are where I marked the steel sections I cut with a center punch. Didn't feel like having the sharpie rub off when I'm moving them around and measuring.  | |

|

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8588

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 16th 2020, 10:44 am January 16th 2020, 10:44 am | |

| That's a Ross made steering box, I have a few tractors that use one. They're awesome for use in garden tractors and make for super nice steering, but I'm not sure how they would hold up to high speed off-road abuse. Rack and pinion might be a good option.

Looking forward to seeing the frame come together! The mock-up you did looks pretty neat.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 16th 2020, 4:56 pm January 16th 2020, 4:56 pm | |

| Thanks. Your right about the box, I noticed it said Ross when I was cleaning some grease off of it. Pretty sure I'll go with the rack unit. I may attach the tie rod ends in a bit closer to the spindles to get quicker steering. Not 100% sure yet. Next step is the cut out a relief for the rack and pinion in one of the lower frame pieces and then weld some steel back in. Pics will explain better once I get it going. | |

|

| |

redzz02

Site VIP

2014 Build-Off Entrant

2014 Build-Off Entrant

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2015

1st Place Winner Build-Off 2015

1st Place Build-Off 2017

1st Place Build-Off Winner 2017

1st Place Build-Off 2018

1st Place Build-Off Winner 2018

Age : 30

Join date : 2010-05-12

Points : 6377

Posts : 899

Location : PA pittsburgh and pymatuning

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 16th 2020, 11:17 pm January 16th 2020, 11:17 pm | |

| Very intriguing set up, loving the shiny wheels and I too would move that motor forward a little more, looking good | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 17th 2020, 12:35 am January 17th 2020, 12:35 am | |

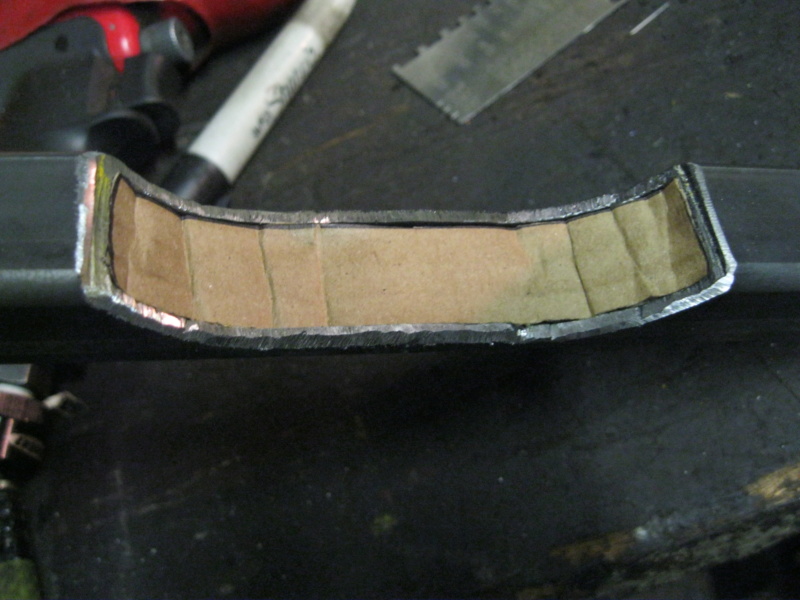

| Thanks. The wheels are from Northern Tool. I would move the engine farther ahead but I'm about at the limit of where I can move it with the suspension arms. Also the steering linkage from the rack and pinion needs to get up over the engine. Farther forward it is, the more angle there will be. I can also move the rear axle a few inches to shift weight distribution a bit. We'll see. I'll definitely be putting the engine as far up as I can. Tonight's work on the lower front frame. They need to be close together to leave enough room for the suspension arms. But to keep them narrow and mount the rack unit where I want, I had some clearance issues. So had to cut out a notch.  Clearance problem solved. Just need to weld it back up. Strength won't really be an issue as there will be a heavy mounting plate for the rack/skid plate welded under this area of the frame. Plus it's right up near the front.  Cardboard template fit in.  A dash to hood brace from my parts sears suburban happens to be the right size.  Bent to the right shape...  Fit in place.  Welded. Still getting used to my new welder and I think it needed to be set a bit hotter. Got the job done but would have looked better if I had it burned in a bit more. Not a huge deal.  Now the rack will fit flush with the bottom, which is where I need it to line up with the wheels. There's limited movement with the inner tie rod ends for suspension travel and I wanted to keep the bottom of the tractor as high as possible for ground clearance. So, it ends up that the rack needs to mount directly to the front skid plate.  Ground clearance in the front will be about 7", the same clearance as the number 64 simplicity has under the transmission skid plate in the rear. If I weld the tie rod mounting points higher on the front spindles, I could pick the front end up a bit higher, but probably only about an inch more max. On the #64, I rarely hit anything, but then again, remember that when the suspension compresses, you'll lose that much in ground clearance. To keep center of gravity down low, you'll need to compromise some clearance. To help the front end situation somewhat, I'll have a heavy steel skid plate attached under the rack unit, then forward to the front of the frame rails. There is will bend upwards at 45 degrees and the upper frame rails will tie into it. Slightly less ground clearance is acceptable between the wheels. Because the wheels keep the machine up over most obstacles. Only very jagged rocks will contact the bottom between the axles. In the middle of the machine, the ground clearance needs to be a bit more. On the #64 the center clearance is between 10-11". On the broadmoor RS I was hoping for 9". The frame will need to be stepped up when we get back to the engine mounting plate. Once the front end is a bit farther along, we'll work our way back and sort that out. | |

|

| |

Hillbilly Offroading

Established Member

2019 Build-Off Entrant

2019 Build-Off Entrant

1st Place Build-Off 2020

1st Place Build-Off Winner 2020

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2018-11-09

Points : 2854

Posts : 582

Location : Reeses Mill, WV

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 20th 2020, 10:00 pm January 20th 2020, 10:00 pm | |

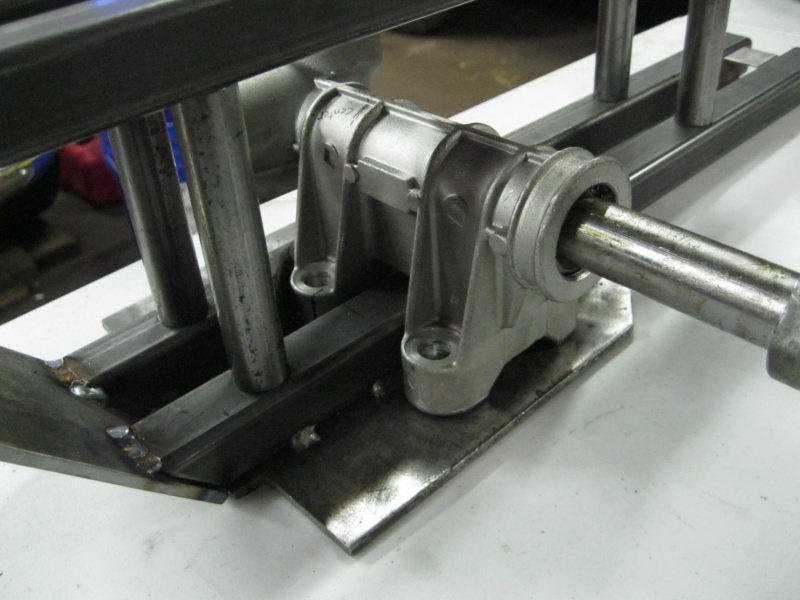

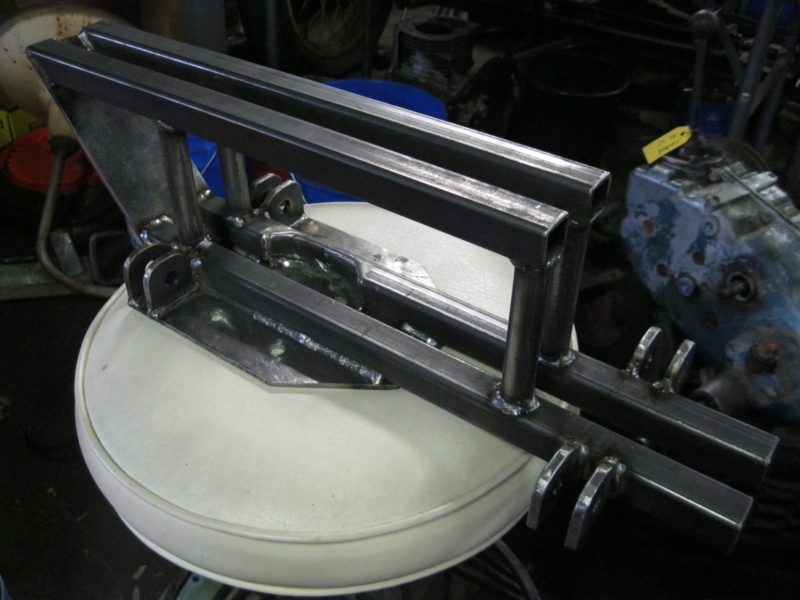

| Thanks! The latest progress from the weekend. I cut out the pieces for the rest of the front frame (mostly). Not yet welded.  The round tubes space the upper and lower sections 4". Enough room to pick the rack and pinion up over the lower frame rails. The skid plates are scavenged sections of sears suburban frame, just shy of 3/16" thick.  The rack and pinion will bolt through the bottom plate. Should be plenty of room for a universal joint on the input shaft.  Still need to weld everything. There will also be some added bracing in places. Once the center section is done, I can start working on the control arms and then shock mounts.  The lower control arms will be symmetrical. The upper control arms will match the lower ones in the front only. The upper arms will be a bit shorter in the rear, because of clearance issues with the engine cylinder head. The original plan was to use round tubing, but because I can't find the correct size tubing to fit my weldable threaded heim ends, I decided to use the same square steel as the frame. The weldable billets fit in snug and it will be easier to cut and weld bends into the arms.  | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7223

Posts : 4021

Location : Lewisburg, KY

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  January 22nd 2020, 1:00 am January 22nd 2020, 1:00 am | |

| Thanks. We'll see how it holds together at the 2020 TTC! Gotta be heavy duty if you wanna just ram head first into rocks and construction debris. | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5982

Posts : 2645

Location : Indiana

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 4th 2020, 10:39 pm February 4th 2020, 10:39 pm | |

| Welded all the tubes and the upper half of the front frame. Also made all the lower control arm brackets but still need to do the top ones. Also will add some light bracing to the front skid plate to keep it from bending inwards during hard hits.  Getting a little bit more used to the new welder. Still didn't get a new camera either...this pic turned out a bit grainy. At any rate, I think the front end should be plenty heavy duty. Possibly this weekend I can figure out how I'm going to tie into the engine mounting plate. That will require some careful measuring to make sure I leave room for the belts to line up with the transmission.  | |

|

| |

BlakeGroce

Member

Age : 21

Join date : 2019-06-02

Points : 2519

Posts : 469

Location : Richmond Ky

| |

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7783

Posts : 3047

Location : Lebanon County, PA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 5th 2020, 1:58 am February 5th 2020, 1:58 am | |

| - mr.modified wrote:

- I've got the two stock engines from Doug (one might have been run low on oil) and the 3 I just bought with the race parts.

Yea, the one had the crank carrier come loose when I was snowblowing and spit all the oil out. Only noticed it after it wouldnt start again. I cant wait to erase your markings this weekend.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 5020

Posts : 731

Location : Logan Ohio

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 5th 2020, 8:42 am February 5th 2020, 8:42 am | |

| Thanks! So far I didn't mess anything up too bad. At least I think...

I've been missing out all this time using the flux core welder. Much less splatter with the gas. | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 5020

Posts : 731

Location : Logan Ohio

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  February 7th 2020, 5:07 pm February 7th 2020, 5:07 pm | |

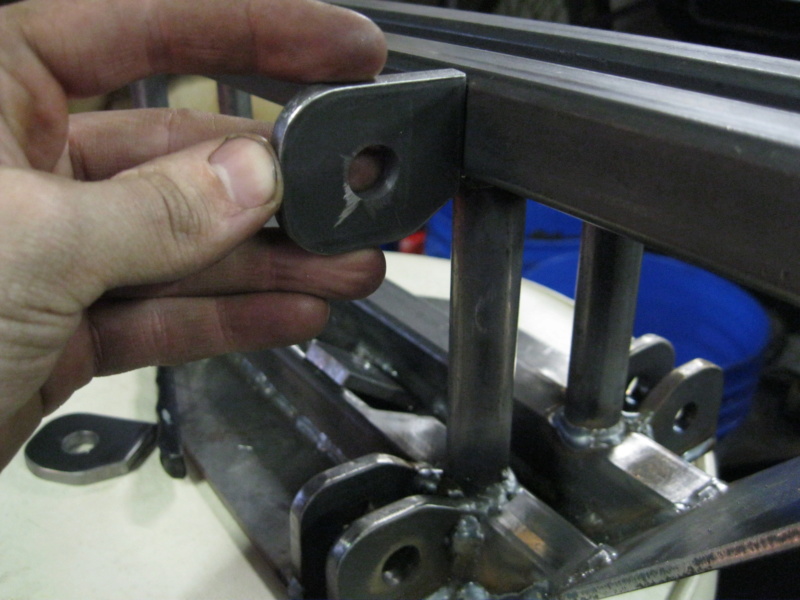

| The suspension bracket making process at Simplicity's racing division... As usual when making a super high tech part, we start with a cardboard template (Labeled as such to prevent accidental disposal) I center punch the hole with the template also while keeping the important flat surfaces that will touch the frame flush with the template.  I drill the hole before making any cuts. That makes it much easier to work with in the drill press. Or to clamp it in a vice for a hand drill. Then make the cuts with a sawzall. On the tabs for the lower suspension, I only rounded one of the outter edges because the bottom butted up against the skid plate. The top ones will stick out in mid air, so both edges get rounded off.  I finish rounding the edges with a normal bench grinder and wire wheel. The most important thing is that the holes are all as close as possible, but the edges seem to come out pretty close as long as I'm careful to always mark and cut about the same way.  Once welded to the frame, I can correct any slight hole alignment issues by running a drill bit through it to ream them out a little. There are of course eight bottom tabs for both lower control arms and eight upper tabs for the upper control arms. Plus there will need to be eight tabs to mount both front shocks (two tabs for top and bottom each) And then later on, mounting tabs for the rear shocks....For now I'll try not to think about how many more I have to cut out.  | |

|

| |

Sponsored content

| |

| |

| | Simplicity Broadmoor R/S Project |  |

|