| | Simplicity Broadmoor R/S Project |  |

|

+17Hillbilly Offroading redzz02 muddstir redlinemotorsportts prancstaman mrshaft696 MightyRaze JohnLidell diddie TheBeal mowerjunkie03 RichieRichOverdrive Mister_Studabaker Creepycrawler AllisKidD21 CraftsmanQuad19 mr.modified 21 posters |

|

| Author | Message |

|---|

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Join date : 2016-04-12

Posts : 2645

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Mon Nov 04, 2019 10:36 pm Mon Nov 04, 2019 10:36 pm | |

| Oh ok I gotcha. I assumed when you said copper head gasket you were running it because it was thinner to boost compression. Didn’t think about copper gaskets being any number of thicknesses haha. My bad | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Wed Nov 06, 2019 10:40 pm Wed Nov 06, 2019 10:40 pm | |

| Some good news and latest progress on the Broadmoor RS project. I found the old rear fender from the simplicity adventure edition. When I built that machine, it really didn't seem to fit too well so I just went without. I never thought I would use it so I stored it in one of my car projects to use for sheet metal. I was thinking I already used some pieces of it, but luckily, I thought about it the other day and found it was still intact! So now I have a good template to use for the RS rear fenders. The thing is, I measured out where the wheels will go and about 4/5th of the tires will stick out from under the edge of the stock fenders. Stock 70's Simplicity Broadmoors were a bit narrow... So some flares will be in order. I'm thinking leave the stock shape of the fender and just have black plastic fender extensions, but we'll see when we get to that point.  The pointed rear section is pretty common to all 70's simplicity's, so I'd like to try keeping a really close shape to the original. That way it will be fairly easy to recognize the look. I may be able to use the original fender as a form for making a fiberglass one. Maybe coat it with something so the fiberglass resin doesn't stick.  Also, I've been emailing a lot of different people online to get more detailed specs on parts. Found out that ARC racing doesn't have charging magnets in any of their billet flywheels. For circle track, a constant loss system might be ok. But for things like Haspin or the Top tractor challenge, I would rather have an on board charging system for the battery. No way I'm adding a heavy automotive alternator to this build, way too much weight and also too much engine drag. I tracked down a small alternator used on kubota engines which might work. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7221

Posts : 4020

Location : Lewisburg, KY

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Fri Nov 08, 2019 12:42 am Fri Nov 08, 2019 12:42 am | |

| Power steering pump for the engine oil you mean? That might work if there was some kinda small one out there. I would think most would be more capacity than I need, but then again maybe not. I didn't think of that before. | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Fri Nov 08, 2019 6:45 pm Fri Nov 08, 2019 6:45 pm | |

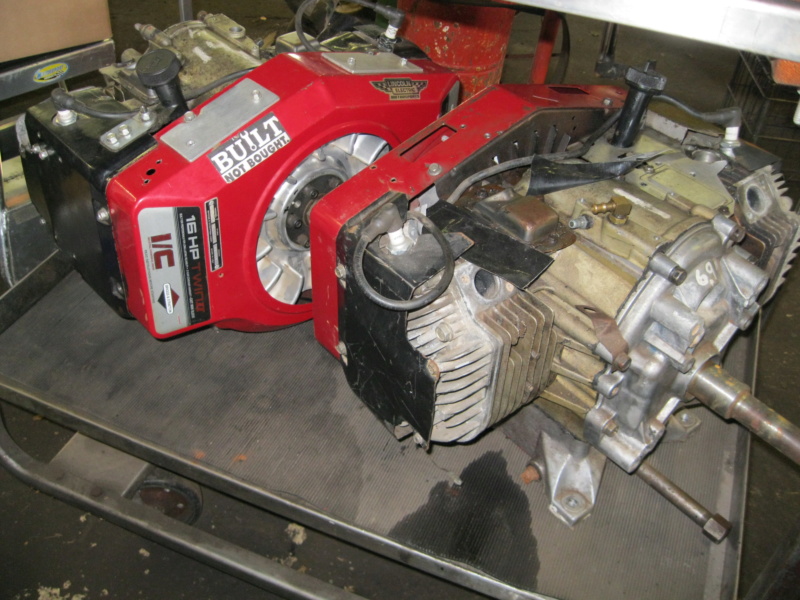

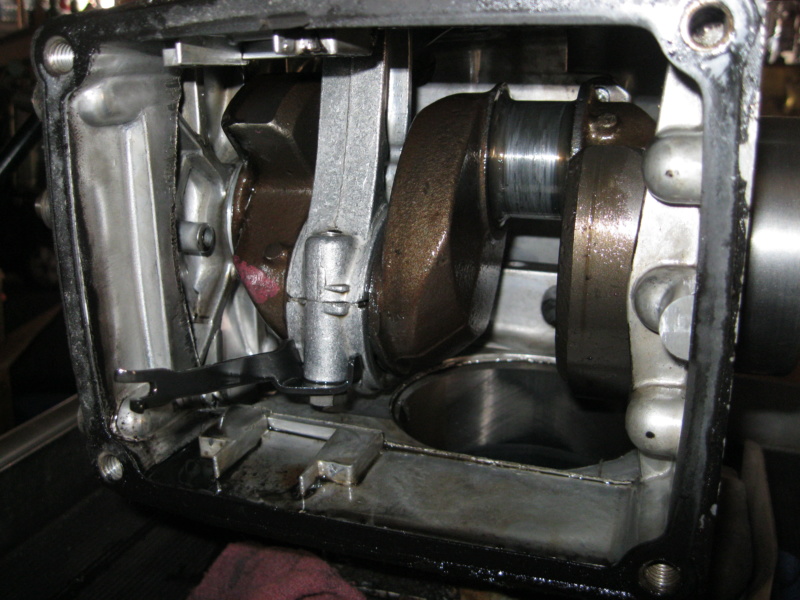

| The diff removed from the older transaxle for locking.  The case finally opened up on the newer trans. Much beefier 6 gear diff instead of only 4. Plus the plate holding it is a lot heavier. Also, many of the gears have thicker teeth (with less quantity, same diameter gear). I need to make sure they are all the same ratios and check them carefully so I can sort out my gearing with the tire sizes and all that later on.  | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Wed Nov 13, 2019 10:52 pm Wed Nov 13, 2019 10:52 pm | |

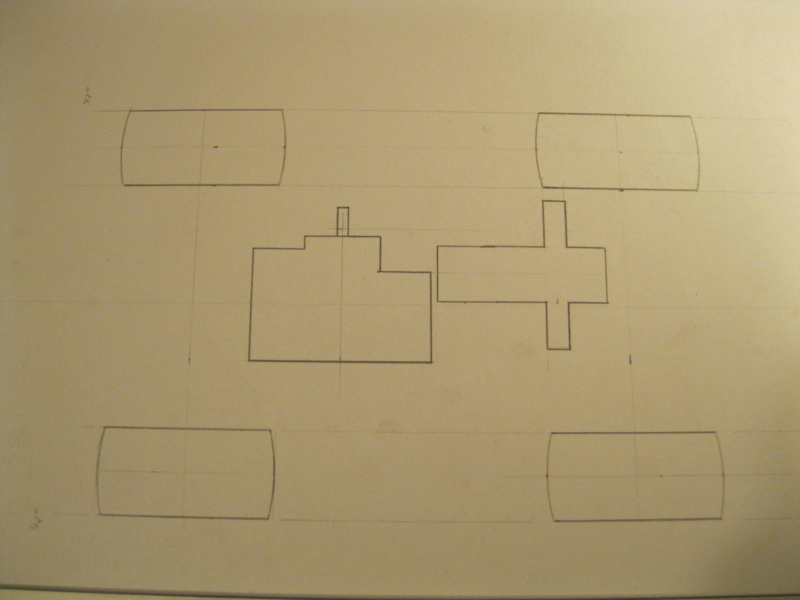

| Finally added wheels to the RS drawing. I was sorting out the distance between the front axle center line and the engine. Also I wasn't sure what wheel size I was going to use for sure, or how much room I needed between the live axle and the 633 axle. So for now here is what I came up with. 42" outside width. Front axle center line to front of engine: 6". 1" between rear of engine and front of 633 transaxle. And from the 633 axle to the live axle is 7". The rear swing arm will be fairly short with this setup but shouldn't be an issue for mild rear suspension. At the moment, I'm not 100% sure on steering placement. I figured 6" would be enough room to fit a golf cart rack and pinion between the engine and front axle line. One possibility is to put the rack in front of the wheels and then you might be able to move the engine and transmission forward a few more inches. But you've gotta keep it back far enough so that the drive pulley clears the front tire. To get more room in the rear, the 633 could be turned upwards at an angle and the 633 axle moved forward somewhat. But this would bring the center of gravity up and also create some possible lubrication issues. The shifter would be at an odd angle too if I went too far. But it shouldn't be necessary to tip it up more than stock. Front of tractor to the left. The 633 is staggered to the right of the machine to line up the pulleys, leaving room for a fuel tank or battery on the left. The opposed flywheel also counter balances the off set transaxle since it's at the far left of the frame. About 1.5" is left for the swing arm attachment on the right 633 axle (which will need to be cut down of course). Everything is going to be very snug, but (hopefully) easy to get at.  Current plan specs: -42" width -44" wheelbase -Wheels (front and rear) 18 x 8.5 x 10 | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Mon Nov 25, 2019 10:23 pm Mon Nov 25, 2019 10:23 pm | |

| Finally tried out the new welder on the older 633 trans. Still have another older style one to lock up that I just removed from a sears suburban. I've been talking to a guy that has some ex-racing opposed engines with ARC parts. Might buy a couple complete engines from him once he figures out what he has. Guess he's gotta dig some of it out of storage. Welded both sides of the gears. Should be pretty solid. On the RS, only one axle will be driving the rear wheels so it's gotta be heavy duty.  | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 5019

Posts : 731

Location : Logan Ohio

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Tue Nov 26, 2019 7:25 pm Tue Nov 26, 2019 7:25 pm | |

| Thanks. The new welder is quite a bit hotter than the old 110v machine I was using before. Works pretty good. And it's way better than all the slag I would get with the flux core stuff. Should be pretty nice for the frame welds and things when I get to that. | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Tue Dec 03, 2019 9:22 am Tue Dec 03, 2019 9:22 am | |

| In the process of searching around for opposed info online, I came across a guy out in pa who made me a deal on some ex drag racing equipment. Bought 3 opposed engines which all have ARC rods and flywheels. They also have some hotted up cams installed with dual valve springs. Not 100% sure what each one has in it as far as cams but I'll find out as I go. The first one I'm taking apart has a broken exhaust valve which beat on the seat a little. Also the cylinders aren't in the greatest shape, but most of the parts should be usable. Hopefully the other two blocks will be in a bit better shape.  Billet!  ARC flywheels don't have internal magnets for the charging system, so I'll need to run a tiny alternator if I want to run lights ect.  | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15675

Posts : 10987

Location : Oklahoma

| |

| |

mrshaft696

Established Member

2018 Build-Off Finalist

2018 Build-Off Finalist

2019 Build-Off Finalist

2019 Build-Off Finalist

2020 Build-Off Entrant

2020 Build-Off Entrant

Join date : 2016-07-10

Points : 4059

Posts : 870

Location : Phillydelphia

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Tue Dec 03, 2019 1:20 pm Tue Dec 03, 2019 1:20 pm | |

| Thanks. And yeah the vertical shaft and horizontal shaft engines are basically the same block. The difference being the end cover and mounting base. On the Horizontal, the base bolts onto where the side cover is on the vertical. Where the vertical has the finned cover. Of course the stock manifolds are different to make the carb sit upright. And the horizontal engines use a dipper on the rod bolts instead of the slinger geared off the cam shaft. At least, that's what this guy has in them. I don't like how they are only hooked on one rod bolt. It's a pretty heavy dipper and I would think at high rpm, it would be hard on the bolt. But he said he never had an issue with it. Either I can build it like it was or find an oil pump like I originally intended.

The first engine seems to have some pressure lube parts in it, but none of the engines I bought are set up for pressure lube. I don't think I want to track down stock pressure lube parts to make it work that way. Just for the sake of simplicity.

Also, it's going to be a bit of a tight squeeze on time getting everything built. Not sure if I'm going to try the supercharger right away. It would require a more elaborate intake manifold and mounting bracket. Plus some tuning, swapping pulleys/drive ratio to get the pressure correct. As it is I have some cams to use and could build a decent naturally aspirated engine and then deal with a supercharger later on if I wanted to.

The plan is to build at least two engines. One for practice running and as a back up engine, this one will probably be de-tuned somewhat and using more worn parts. Then the best parts will be in the race engine which will be built a bit more on the edge of blowing up and saved for actual race conditions when I need it.

| |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Thu Dec 05, 2019 9:28 pm Thu Dec 05, 2019 9:28 pm | |

| Continuing disassembly of the first engine. One of the ARC rods has a bit of a spot near the crank bearing on the side. It may have been ground out for cam clearance. Either that or it made contact with the cam but I think material was removed there. Nothing that should weaken it. Some pretty fancy racing pistons in there too with pretty thin low drag rings. Unfortunately the pistons in this engine have quite a bit of wear on them. Even so, they're not so bad that I can't use them for a back up or practice engine. Time will tell how the other engines are.  Side by side with a stock piston and rod. Pics didn't come out great, had some bad lighting...  | |

|

| |

Creepycrawler

Established Member

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 37

Join date : 2013-07-02

Points : 5019

Posts : 731

Location : Logan Ohio

| |

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 5096

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Fri Dec 06, 2019 7:41 pm Fri Dec 06, 2019 7:41 pm | |

| Looks like the ARC rod is longer with a shorter piston, compared to the stock rod and piston. But same overall length from crank journal to top of piston. Cool. | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5981

Posts : 2645

Location : Indiana

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Fri Dec 06, 2019 8:00 pm Fri Dec 06, 2019 8:00 pm | |

| That’ll give it less connecting rod angle. Will hold together better at higher rpms and with a better cam will extrnd the power band drastically | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Fri Dec 06, 2019 11:19 pm Fri Dec 06, 2019 11:19 pm | |

| Thanks. Yeah I've got a decent stock pile of stuff now. I think those rods should be the same length, but there are different ones for the 3 different size engines. (Edit: it does look like the wrist pin is closer to the top on the race piston. Maybe that stock rod is from a 46CI though, I don't know)

From what I understand, all three opposed engines use the same block with different strokes. The early 40 cubic inch ones, the most common 42CI ones, and the 46CI ones made for a few years at the end of production. The difference being longer stroke cranks and slightly shorter rods as the stroke length increases. All use the same bore except there was supposedly a rare 46CI engine with a larger bore and same stroke as the 42CI engines. Possibly the 22hp 46CI engines were all that way.

I'm not sure if I have any 46CI engines here or not. I think the one I took apart was a 46CI block originally because it has some extra machining inside for rod clearance. (now with 42CI crank and rods)(Longer stroke needs more clearance in the block, otherwise the rods would hit)

This weekend I'm going to try to take apart the other engines to see what's in them and try to decide what block I'm going to use first. I've got the two stock engines from Doug (one might have been run low on oil) and the 3 I just bought with the race parts. | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Sun Dec 08, 2019 7:19 pm Sun Dec 08, 2019 7:19 pm | |

| Guess you guys are right about the pistons and rods being longer. I checked them a bit closer and these rods are longer than stock with the wrist pin a lot closer to the top of the piston. The rods are marked 42. So I have to check on arc's website and see what they're supposed to be. As far as I can tell, all 3 of the race engines have 42CI cranks in them. But I could be wrong. I guess the advantage of a longer rod and moving the wrist pin up would be less side pressure against the cylinder wall and therefore less drag. I would imagine less drag on the bearing too.  Here's one of doug's stock engines. In stock form the horizontals use a dipper on one rod instead of the plastic flipper that the verticals use. This engine has some wear on the cylinders and one rod was burned up. I think the crank is ruined also. Still did not get the other stock engine apart yet to see if that one is good.  Stock base from the engine with the burned up rod. The dipper fits down in that tin windage tray thing. Not sure what advantage that is with a splash system. Maybe it's meant to throw the oil up better. I'm still leaning towards a pump system on my build if I can find a good pump to use. Electric pumps are out there but very pricy. Mechanical driven pumps are out there too, but bulky, large, heavy, and you have to drive it off the crank or something with a chain. An electric pump you can mount anywhere, but if you lose power or your charging system, you've gotta stop or burn up the engine.  Pulled one head each off the other two race engines. Both of these look like they have better cylinders, so that's good news. The one on the left is slightly better than the other. If you look in the right of the picture, you notice the crank shaft has a big shoulder on it. I think all three of these race engines have vertical shaft cranks in them. The only difference being that shoulder. It may be a pain for me to use them that way because of the transaxle placement. I can either make a pulley system to fit over the shoulder or swap to a horizontal crank which has the keyed part closer to the block. Problem is I have only one of those cranks from the stock engine I didn't take apart yet. As long as that one is good. I might be able to find another crank on ebay if I need it.  Trying to keep things organized.... Once I check out the other two race engines a little closer and the stock engine I didn't take apart yet, then I can decide what will be the main race engine and which one will be the backup engine. I'm thinking build one supercharged and one naturally aspirated for practice running.  | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Sat Dec 21, 2019 12:10 pm Sat Dec 21, 2019 12:10 pm | |

| Trying to figure out what I need to order for the front suspension. Two options for using the golf cart front axle I have. --Option 1: Use the golf cart spindles (and the golf cart axle ends) connected solid to one pivot point, basically one control/A arm. Easier to make but more wheel tip with suspension movement and bump steer issues as we get into more travel. --Option 2: Ditch the golf cart axle entirely using only the spindle and hub. Get a longer bolt for the spindle and use heim joints top and bottom as ball joints. Then have upper and lower control arms for a "correct" front suspension. Bit more work but would be less or no bump steer and little wheel tip. Leaning towards this option. The spindle bolts are 5/8" so I would need 4 5/8" Heims and 8 1/2" Heims for the control arm pivots.  In other news, my wheels and super light weight seat came in the mail over the past week or so. | |

|

| |

RichieRichOverdrive

Moderator

2018 Build-Off Entrant

2018 Build-Off Entrant

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 22

Join date : 2016-10-29

Points : 7221

Posts : 4020

Location : Lewisburg, KY

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Sat Dec 21, 2019 10:59 pm Sat Dec 21, 2019 10:59 pm | |

| Yeah, those are vertical cranks. Wonder why they went with them rather than horizontal ones. Bet it has something to do with the aftermarket parts.

I'd pull apart my pressure lube horizontal and get some pics for you if I trusted myself to put it back together.

Wonder what it'll be like messing with the ignition timing on those flywheels. | |

|

| |

redlinemotorsportts

Moderator

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 27

Join date : 2013-03-18

Points : 7483

Posts : 3131

Location : raleigh nc

| |

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7169

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Thu Jan 09, 2020 8:31 am Thu Jan 09, 2020 8:31 am | |

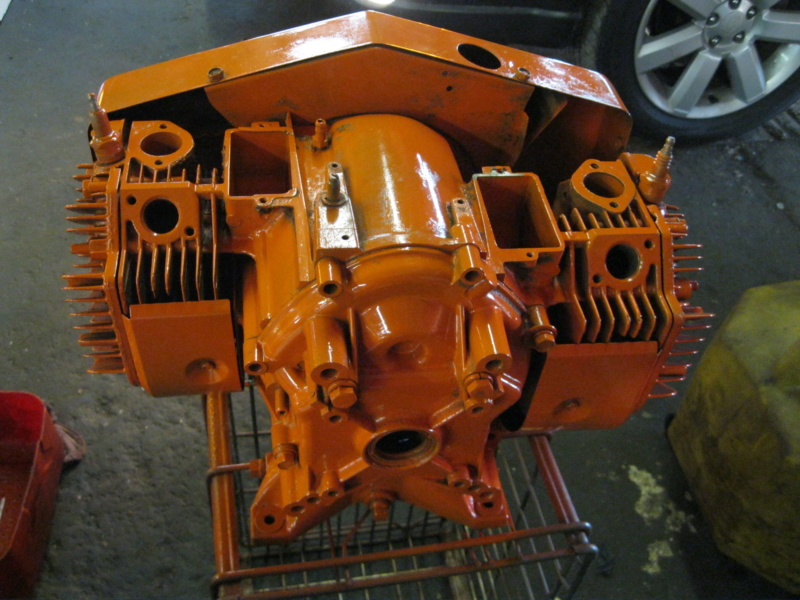

| The ARC flywheels have some fancy marks on them so you can see where it's set. Sort of an odd setup but it seems rugged enough. Those uniball things have the spindle bolt go all the way through same as the heim joints? They do look pretty heavy duty. Haven't had any updates in a little while but still working on things. Ordered a golf cart rack and pinion which came in.  I should have pretty much everything needed to start working on the front suspension and forward part of the frame.  Also assembled a dummy block with no crank or flywheel. When I'm building the frame, this will be easier to lift and move around when I need to mock things up.   | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15675

Posts : 10987

Location : Oklahoma

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Thu Jan 09, 2020 8:55 am Thu Jan 09, 2020 8:55 am | |

| Nice idea. I have a couple opposed blocks hanging out myself.

You know how you are going to negotiate the input going to the outside instead inside? I have a similar and z bends with universals seemed to bind up for me. | |

|

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8587

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Thu Jan 09, 2020 10:08 am Thu Jan 09, 2020 10:08 am | |

| The rack I put in my GT6000 was like that as well, but offsetting the rack on the front axle and using a couple different universal joints worked pretty well. Of course I only had the rack going to one steering arm and used a tie rod, if you wanted the rack and pinion to steer both wheels it'd be a little bit trickier to mount it offset.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5981

Posts : 2645

Location : Indiana

|  Subject: Re: Simplicity Broadmoor R/S Project Subject: Re: Simplicity Broadmoor R/S Project  Thu Jan 09, 2020 5:43 pm Thu Jan 09, 2020 5:43 pm | |

| That was the biggest challenge for me. Finding a rack narrow enough with a center input that’s straight. Pretty tough to do really | |

|

| |

Sponsored content

| |

| |

| | Simplicity Broadmoor R/S Project |  |

|