| | Welding Table build |  |

|

+4MightyRaze Doug CraftsmanQuad19 muddstir 8 posters |

| Author | Message |

|---|

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Welding Table build Subject: Welding Table build  January 13th 2018, 10:26 pm January 13th 2018, 10:26 pm | |

| I been building a welding table for awhile now. The lower section is done and i'll be starting on the top once i go get more steel. I dont have a bunch of pics of what i got done so far but i got enough to make a build. I wanted a good sturdy welding table that had a sectional top that didnt need holes drilled in it for clamps. So i did a search online and came across one that used c-channel as a top surface. So thats what ill base my top off of. The other stipulations were lenght between 60 and 72in long, top 32in wide with 4in overhang on front and back side. Height had to work at a comfortable sitting position. So i went to the metal supplier and picked up the steel for the lower frame work. 2x4x.125wall rect tube 1.250 x 1.250 x .250 angle iron 1 x 2 x .125 rect tube 2.500 x .187 square tube 6In std weight c-channel .125 thick tread plate This is some of the metal from above list  Upper framework welded  Welding legs on  Setting in lower shelf (table is upside down on the cart)  Lower shelf in and sitting upright  Lower shelf covered and now your up to date.  | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5982

Posts : 2645

Location : Indiana

| |

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7783

Posts : 3047

Location : Lebanon County, PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 13th 2018, 10:51 pm January 13th 2018, 10:51 pm | |

| I like how the bottom shelf is angled in for foot space. I bought some Edsal table legs to make new benches, going to use 2x4s I got from work for free as a new wall length bench. THought of laying some 1/4" plate across the top so I can weld on it too. Cant wait to see how your channel top works out.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15677

Posts : 10988

Location : Oklahoma

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 13th 2018, 11:20 pm January 13th 2018, 11:20 pm | |

| That is super nice! Nice and sturdy looking. Bet it weighs a ton. Excellent! | |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 14th 2018, 7:33 pm January 14th 2018, 7:33 pm | |

| Nice deal. What do they use for a top piece? Do people use stainless or something so weld splatter doesn't stick? | |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 14th 2018, 8:37 pm January 14th 2018, 8:37 pm | |

| Thanks guys

Doug- I'd put a pc of plate steel on top of your work bench or i'd have a manageable pc laying around that you can throw up there when you need to weld something. You get that work bench built post some pics up, i enjoy looking at home built shop stuff.

Mightyraze- I'd guess around 300 lbs so far as it sits. When finished Im taking it to work and weighing it.

Mr.modified- they use anything flat for a top its really personal preference. I am going with steel c-channel. Weld splatter usually knocks right off with a scrapper and if it dosen't then a flap disk takes care of it.

I also picked a steel top over a aluminum or stainless top for these other reasons

1. I can weld to it if need be

2. Can use welding magnets on it

3. It can take more abuse (than alum). | |

|

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7783

Posts : 3047

Location : Lebanon County, PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 14th 2018, 10:20 pm January 14th 2018, 10:20 pm | |

| Stainless will also run a small fortune.

I definitely plan on taking pics or video when I construct mine. I should take my current welding table and weigh it. It probably weighs at least 500lb.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|

| |

mr.modified

Veteran Member

2015 Build-Off Top 3 Winner

2015 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2016 Build-Off Top 3 Winner

2018 Build-Off Finalist

2018 Build-Off Finalist

2022 Build-Off Entrant

2022 Build-Off Entrant

1st Place Build-Off 2014

1st Place Build-Off Winner 2014

2023 Build-Off Entrant

2023 Build-Off Entrant

Age : 34

Join date : 2013-11-02

Points : 7170

Posts : 2910

Location : New Jersey USA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 15th 2018, 11:23 am January 15th 2018, 11:23 am | |

| I didn't even think about welding magnets not sticking to stainless. Looks pretty neat though. I need to build one. Usually I'm kneeling on the floor bent over an old metal crate. | |

|

| |

biggasmowers

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 24

Join date : 2016-12-30

Points : 4931

Posts : 1944

Location : Kansas

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 15th 2018, 12:19 pm January 15th 2018, 12:19 pm | |

| Very nice table! I've been wanting to build a nice welding table for awhile but have not gotten going on plans yet. | |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 20th 2018, 9:03 pm January 20th 2018, 9:03 pm | |

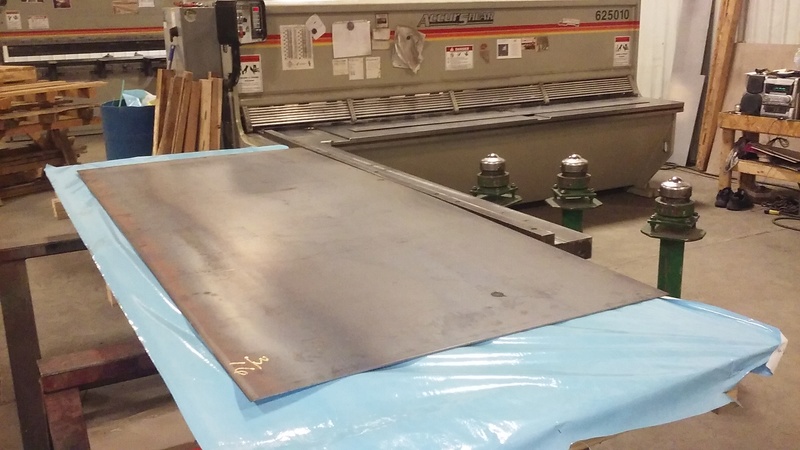

| Went today and bought a full sheet of 3/16 thick steel plate. Then took it to work and sheared some strips off for boxing in the c-channel on the bottom side.  Here is all the cut pcs at home with one placed on the c-channel ready for welding. I am going to cut the sides of the channel at a 45.  | |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 27th 2018, 7:19 pm January 27th 2018, 7:19 pm | |

| Did some corner notchin this past week. Measured in 2in on the one end and 2 3/8 on the other, then used an angle grinder with a cutoff wheel. There are 44 corners total and I've done 15. Might take awhile.   | |

|

| |

biggasmowers

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 24

Join date : 2016-12-30

Points : 4931

Posts : 1944

Location : Kansas

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  January 27th 2018, 8:37 pm January 27th 2018, 8:37 pm | |

| How much does a sheet of 3/16 cost? Iv'e never had the guts to ask at the metal yard lol | |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 15th 2018, 8:25 pm February 15th 2018, 8:25 pm | |

| The 3/16 plate ran me $135 and that was the cheapest i found it for. I got some more work done to this over the past week. Got all the top c-channel angle cut and got all the strips of plate ground/prepared for welding to the c-channel.  | |

|

| |

biggasmowers

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 24

Join date : 2016-12-30

Points : 4931

Posts : 1944

Location : Kansas

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 16th 2018, 11:00 am February 16th 2018, 11:00 am | |

| Ouch ! thats some pricey steel, but cheaper than stainless or aluminum i guess. Oooh a TIG machine!

| |

|

| |

muckmudd

Established Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Age : 22

Join date : 2017-07-11

Points : 3562

Posts : 825

Location : In the shop

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 16th 2018, 11:14 am February 16th 2018, 11:14 am | |

| That's so nice. My welding table is a school desk with a metal top attached to it.

| |

|

| |

biggasmowers

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 24

Join date : 2016-12-30

Points : 4931

Posts : 1944

Location : Kansas

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 16th 2018, 11:25 am February 16th 2018, 11:25 am | |

| My welding table is...... well i just use the concrete floor. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15677

Posts : 10988

Location : Oklahoma

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 16th 2018, 12:09 pm February 16th 2018, 12:09 pm | |

| - biggasmowers wrote:

- My welding table is...... well i just use the concrete floor.

Ditto. | |

|

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7783

Posts : 3047

Location : Lebanon County, PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 17th 2018, 2:04 am February 17th 2018, 2:04 am | |

| That gives me a good idea for my table, just frame a mold and pour a layer of concrete onto it. Brilliant!  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15677

Posts : 10988

Location : Oklahoma

| |

| |

biggasmowers

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 24

Join date : 2016-12-30

Points : 4931

Posts : 1944

Location : Kansas

| |

| |

TheBeal

Veteran Member

Age : 30

Join date : 2013-06-06

Points : 5718

Posts : 1402

Location : Central PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 17th 2018, 2:05 pm February 17th 2018, 2:05 pm | |

| I dont know about that, it would see some heat sure, but not really concentrated, or sustained long enough to make things asplode? I like the idea of using c channel. If one gets too buggard up knock it out and drop in a new one. Like to build one someday, I was thinking using angle iron sorta like /\ /\ /\ /\ /\ /\ /\ /\ then I could have a 1/4in plate that could be man handled on top if needed. But man, all those angled cuts??? Thats dedication right there.  {EDIT} Will you be making any sort of uprights to tack stuff to? At voteck the little tables we had in the booths had some uprights to tack stuff to for uphill, or overhead welding. Also, a chunk of bar stock off the side to hand the stinger on was nice. | |

|

| |

Doug

Site Owner

2014 Build-Off Entrant

2014 Build-Off Entrant

2017 Build-Off Entrant

2017 Build-Off Entrant

Age : 29

Join date : 2012-12-24

Points : 7783

Posts : 3047

Location : Lebanon County, PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 17th 2018, 5:41 pm February 17th 2018, 5:41 pm | |

| If I were to do it I would add mesh and steel reinforcement.

Ive seen tables where they have holes lazer cut for pegs or clamps to run through.  Head Forum Administrator ** Chat Moderator ** Facebook Page AdminATLTF Facebook Page ** Chatbox ** How To Upload Pictures

_X_ FORUM ANNOUNCEMENTS _X_Have a question? Ask me! Type in "@Doug" in your post!

Your ATLTF Staff:

Administrators: @Doug, @MightyRaze, @"Doc Sprocket", @Stretch44875

Moderators: @TheRainbowBoxer, @AllisKidD21, @Brianator, @RichieRichOverdrive

| |

|

| |

muddstir

Member

2018 Build-Off Entrant

2018 Build-Off Entrant

Join date : 2012-01-22

Points : 5038

Posts : 318

Location : Western,PA

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 17th 2018, 7:34 pm February 17th 2018, 7:34 pm | |

| With my c-channel top each pc will be removable. Each pc will have a toggle clamp on the bottom of it flip the handle and remove. So the top can have any arrangement at any given point a time, from solid top to open framework in a minute. | |

|

| |

biggasmowers

Veteran Member

2018 Build-Off Finalist

2018 Build-Off Finalist

Age : 24

Join date : 2016-12-30

Points : 4931

Posts : 1944

Location : Kansas

|  Subject: Re: Welding Table build Subject: Re: Welding Table build  February 18th 2018, 12:14 am February 18th 2018, 12:14 am | |

| Woah ! That's a very cool design . Not just your run of the mill welding bench. | |

|

| |

Sponsored content

| |

| |

| | Welding Table build |  |

|