|

| | Somebody please!!!! |  |

|

+7TroyBilt Pony Stretch44875 TheRainbowBoxer Doug Doc Sprocket Moose T-Dub13 11 posters | |

| Author | Message |

|---|

kieranruffell

Member

2014 Build-Off Entrant

2014 Build-Off Entrant

Join date : 2014-01-22

Posts : 43

| |   | | Lawren Wimberly

Established Member

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 57

Join date : 2013-12-21

Points : 4807

Posts : 744

Location : Salem Illinois

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 2:48 am March 4th 2014, 2:48 am | |

| That pipe is 1/2 to 5 /8 thick... MUCH stiffer and stronger than the 16 gauge steel drums. I've worked with pvc of this nature... it is TOUGH. | |

|   | | T-Dub13

Established Member

Age : 55

Join date : 2013-12-06

Points : 4574

Posts : 540

Location : Central MA

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 9:54 am March 4th 2014, 9:54 am | |

| It's slippery too. Best bet IMHO. As long as you have the tooling to weld it. You could also buy Auger material right off the shelf for $3/foot. 1"x1" x 4'. Start welding and warm it up to conform to the shape and continue welding. 1 x 1 x 48 HDPE square rodI want to do this, but can only dream and scheme as of now. Too many other projects going on!  | |

|   | | Stretch44875

Administrator

Age : 49

Join date : 2012-04-05

Points : 5703

Posts : 959

Location : Mansfield, Ohio

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 10:57 am March 4th 2014, 10:57 am | |

| A plastic drum is okay, but using the plastic as an auger won't work. The augers are a high wear item on this build. Also, you don't want a knife edge auger, like a grain auger, it would wear and bend easy. We plan to use 3/4 in round stock steel, heated and bent to an auger profile, with about 2 in steel plates spacing it away from the drum.

Right now our tough spot is getting a drum. 100lb propane tanks may work, but don't provide enough flotation with just 2. They already have a taper at the front also.

55 gallon drums would be too weak. 35 gallon drums might work, but worried about them denting/bending also.

Plastic drums, and then bolt the auger to it, may work. But worried about sealing where the bolts are, and if they would wear a larger hole in the plastic.

Another thing, is the direction of the augers. They have to be opposite thread, one is counter clockwise, other is clockwise, to work against each other and propel you forward. Also the angle may be important. | |

|   | | T-Dub13

Established Member

Age : 55

Join date : 2013-12-06

Points : 4574

Posts : 540

Location : Central MA

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 11:18 am March 4th 2014, 11:18 am | |

| The pitch of the auger is a definite consideration. I'd imagine that a low pitch count would be best for high speed work while a high pitch count would require more drum RPM's but provide tractor like pulling power. Also, if designing for speed, I think a lower auger profile would work well, but for pulling a tall auger would get better grip. You bring up a good point: How would anyone "bullet point" the front of a HDPE pipe? I'd try setting it on rollers and turning it slowly. I'd apply heat and force (like metal spinning technique) and see if that works. Might, might not... Hmmmmm I'm not convinced that having the auger mounted off of the surface of the drum would be beneficial. If I wanted more traction, I'd design a tall thin fin type auger. And maybe weld pipe on the tip of it for wear. 2" standoffs would be weaker than surface mounted and also provide no propulsion... Maybe I'm not understanding your design...   | |

|   | | Moose

Established Member

Age : 35

Join date : 2014-01-12

Points : 4953

Posts : 919

Location : Defiance, Ohio

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 11:21 am March 4th 2014, 11:21 am | |

| I was thinking about doing a narrow V like they used on the russian zil seemed to work ok think there is a shop around here that can roll 1/4 plate into a drum too | |

|   | | frostypaws

Member

2014 Build-Off Entrant

2014 Build-Off Entrant

Age : 30

Join date : 2012-07-01

Points : 4691

Posts : 131

Location : iowaaaa

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 11:58 am March 4th 2014, 11:58 am | |

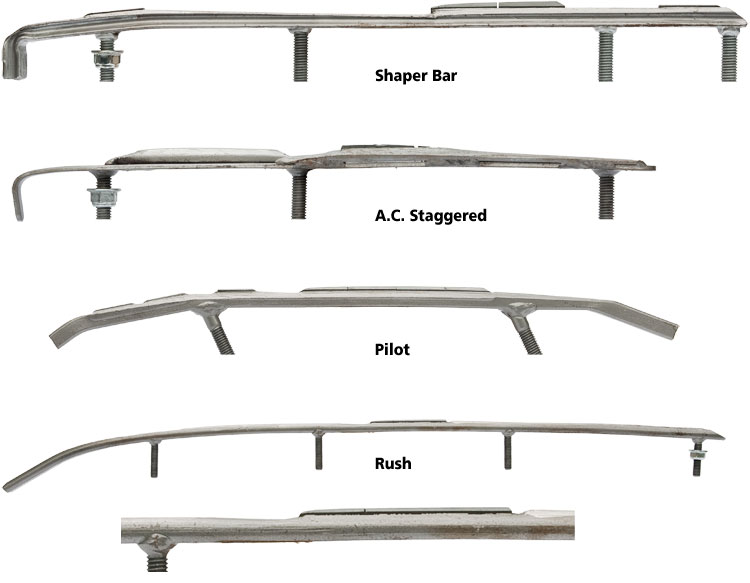

| Hey something I know about lol. Like Moose said the V-fin of the ZIL vehicles (both 2906 and 4904) should be adequate for softer soils, you will have to crab on hard pack :/. The ZIL 2906 has a helix angle of 39° with respect to the central axis of the screw and the ZIL 4904 has a helix angle of 34°. The fin depth on the 4904 is 150mm with a drum diameter of 1.2m. I think the higher the thread count the more at risk you are at shearing the soil behind the auger fin, especially in water logged soils. Here is an illustration of the 4904.  | |

|   | | T-Dub13

Established Member

Age : 55

Join date : 2013-12-06

Points : 4574

Posts : 540

Location : Central MA

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 12:04 pm March 4th 2014, 12:04 pm | |

| Take a look at the skis on a snowmobile. High wear item. They used to be steel until everyone figured out that they suck, stick, rust, wear, spark and bend. Plastic is the way to go with a high wear item that will be subject to snow and water. Plus, I'd bet that if you made an auger out of steel, I could ruin it with a 5lb handheld sledge. I'd also bet that you wouldn't do much damage to an HDPE auger drum with the same sledge. You might get the sledge bounce back at your face though...   I guess if you were to design augers for mud and dirt the design would be different, more like that russian monster above. But I'm thinking snow and water, sometimes mud leaves, pine needles etc. HDPE will survive an EMERGENCY road crossing without getting ruined. Good to know about the pitch angle! I was thinking 45* from the axis. That's a pretty agressive angle though. It actually looks more like the pitch angle is measured from the perpendicular line though. Strange... Optical illustion maybe? Also, I take back the statement about using an open diff and steering with L&R brakes. Even thought it world work, it would be a waste of available energy, and brake shoes. Now I'm thinking hydraulics with a proportioning valve for steering.

Last edited by T-Dub13 on March 4th 2014, 3:10 pm; edited 1 time in total | |

|   | | Moose

Established Member

Age : 35

Join date : 2014-01-12

Points : 4953

Posts : 919

Location : Defiance, Ohio

| |   | | T-Dub13

Established Member

Age : 55

Join date : 2013-12-06

Points : 4574

Posts : 540

Location : Central MA

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 4th 2014, 3:11 pm March 4th 2014, 3:11 pm | |

| - Moose wrote:

- Humble they use it for skid plates on crawlers

Huh? I don't get it.  What do they use?  | |

|   | | Stretch44875

Administrator

Age : 49

Join date : 2012-04-05

Points : 5703

Posts : 959

Location : Mansfield, Ohio

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 5th 2014, 6:34 am March 5th 2014, 6:34 am | |

| In our case, we would be running on rock and dirt, and snow/water. Could crab walk it, maybe make the seat and controls swivel.

The reason for a stand off is propulsion in water.

Very nice frosty! I will be taking a closer look at that for sure. | |

|   | | T-Dub13

Established Member

Age : 55

Join date : 2013-12-06

Points : 4574

Posts : 540

Location : Central MA

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 5th 2014, 8:52 am March 5th 2014, 8:52 am | |

| WOW, Rocks and dirt too? That's some pretty abrasive stuff there. I can see your choice of material and construction now. I'm dreaming up a snow and water only machine, hence the plastic, more like a pontoon tractor lol. Lots of floatation. I never want to get stuck again in 3' of snow on my tractor!!!   Crab walking OMG! You effin solved it buddy!!!  Would be easy with hydraulics. Roll right across the street sideways... Like a boss lol!!! I wonder if the parts from a commercial walk-behind would make a good driveline. A zero turn mower driveline would be kickass.   I would consider eliminating the steering wheel and replacing them with two joystick controllers for the hydros. It would allow crab walking and zeroturn capabilities too. SO many options!  | |

|   | | Stretch44875

Administrator

Age : 49

Join date : 2012-04-05

Points : 5703

Posts : 959

Location : Mansfield, Ohio

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 5th 2014, 9:34 am March 5th 2014, 9:34 am | |

| Thinking we may need to replace the fin's every couple of years, depending on use. As far as the build, it's going to be a balancing act between angles, use for water/snow vs rock dirt, and trying to maintain a low CG for hill use.

Looking at the print, I see they use a v shape for the fin. May need to add that to our thinking. I could collapse the angle on some 2" angle iron, and curve it to match the drums.

For a water/snow machine, I think the plastic would be ideal.

The main reason we want to tackle this project is I have a zero turn with dual hydrostatic transmissions. It uses dual levers, and I think would be ideal to power a tracked machine, or a screw drive. | |

|   | | Moose

Established Member

Age : 35

Join date : 2014-01-12

Points : 4953

Posts : 919

Location : Defiance, Ohio

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 5th 2014, 10:24 am March 5th 2014, 10:24 am | |

| lol thats why I dont like auto correct was supposed to say UHMWPE its pretty wear resistant a lot of cutting boards are made from it but it isnt cheap... | |

|   | | T-Dub13

Established Member

Age : 55

Join date : 2013-12-06

Points : 4574

Posts : 540

Location : Central MA

|  Subject: Re: Somebody please!!!! Subject: Re: Somebody please!!!!  March 5th 2014, 10:39 am March 5th 2014, 10:39 am | |

| @Moose lmao Auto co-wrecked haha. @ Stretch, the collapsed angle is a great idea. A continuous "standoff" and a triangle is strongest. Add a 1/4" wear rod on top like the skegs on a snowmobile and make them replaceable. You could even do carbides like snowmobile skegs at the beginning of the auger to cut through the tough stuff.... Bet you could find a used set of skegs easy enough.  | |

|   | | Sponsored content

| |   | | | | Somebody please!!!! |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 15 users online :: 0 Registered, 0 Hidden and 15 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|