| | Tour1 Transaxle issue |  |

|

|

| Author | Message |

|---|

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 15th 2019, 11:18 am June 15th 2019, 11:18 am | |

| My recently acquired tractor made a pop sound and stopped moving, free wheeled in every gear. During troubleshooting the left half shaft came out without using tools. The groove in the shaft looks ok to me, having no experience.

It's a craftsman 4 speed, probably a 1988. It had 18.5" tires and I just put new 20" on it (sale priced and they fit). All options are on the table. I have self-taught stick welded but don't have a welder now so parts are probably cheaper.

Last edited by Tour1 on June 16th 2019, 12:23 am; edited 1 time in total (Reason for editing : deleted picture link) | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5981

Posts : 2645

Location : Indiana

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 15th 2019, 2:20 pm June 15th 2019, 2:20 pm | |

| Looks like your spider gear let loose or the snap ring on the end of the axle shaft let go. Hard to say without taking it apart but that’s my guess | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 16th 2019, 2:09 am June 16th 2019, 2:09 am | |

| I'm sure it's the snap ring, everything works normal except the axle comes out.

I tried to open the case but forgot/missed the 2 screws in the middle.

Packing up for the night I thought of another option: My tractor doesn't use the outboard mounting holes so I could use a dremel to make a new groove in the axle just outside the seal. Then a standard wheel e-clip could be installed there and a pair of angle iron pieces with half a 3/4" hole in each could clamp outboard of the e-clip and be held by bolts passing through the unused mounting holes.

I would have to shorten the spacer and it would put a weak spot at the worst possible place.

A thrust bearing would fit too, but adds work etc. I made a sketch but can't get it posted at the moment.

The alternative is to keep going with the case split but the ID tag is long gone and I don't know what I'm trying to fix, maybe can't get parts either.

BTW, I bought a 5 speed on ebay, it should be here in 10 days. It could have the same problems though.

It has the same top half of the case. I expect there is little or no mod required for the extra gear. Maybe another lesson is coming soon.

| |

|

| |

prancstaman

Veteran Member

Join date : 2015-02-02

Points : 5096

Posts : 1412

Location : Cleveland,Ohio

|  Subject: Tour1 Transaxle issue Subject: Tour1 Transaxle issue  June 16th 2019, 12:07 pm June 16th 2019, 12:07 pm | |

| - Tour1 wrote:

- I'm sure it's the snap ring, everything works normal except the axle comes out.

I tried to open the case but forgot/missed the 2 screws in the middle.

Packing up for the night I thought of another option: My tractor doesn't use the outboard mounting holes so I could use a dremel to make a new groove in the axle just outside the seal. Then a standard wheel e-clip could be installed there and a pair of angle iron pieces with half a 3/4" hole in each could clamp outboard of the e-clip and be held by bolts passing through the unused mounting holes.

I would have to shorten the spacer and it would put a weak spot at the worst possible place.

A thrust bearing would fit too, but adds work etc. I made a sketch but can't get it posted at the moment.

The alternative is to keep going with the case split but the ID tag is long gone and I don't know what I'm trying to fix, maybe can't get parts either.

BTW, I bought a 5 speed on ebay, it should be here in 10 days. It could have the same problems though.

It has the same top half of the case. I expect there is little or no mod required for the extra gear. Maybe another lesson is coming soon.

Here's a few suggestions. To get to the center bolts for splitting the cases, assuming pulley won't come off, drill a big enough hole through the pulley where you think bolts are that is big enough for a socket to go through. For the e-clip idea, instead of an e-clip use a lock collar. If anything, should be long enough to where you won't need a spacer. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15675

Posts : 10987

Location : Oklahoma

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 16th 2019, 1:00 pm June 16th 2019, 1:00 pm | |

| - Spoiler:

Split this into it's own topic. Please do not hijack other's topics.

Last edited by MightyRaze on June 25th 2019, 9:17 am; edited 1 time in total | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 17th 2019, 12:27 am June 17th 2019, 12:27 am | |

| Ok, next time I'll start a new thread. I used a steering wheel puller to get the pulley off by drilling & tapping 2 existing holes out to 3/8-16. I was following the Peerless manual which said to take out the set screw, spring, and ball that acts as the detente for each gear. There are 2 set screws on my trans, which says FooTe 3864 on the bottom of it and FooTe 3865 on the top. I couldn't get the set screws out & one is now mush, only drilling & tapping will fix it unless it comes out by magic. If the set screws need to be out for re-assembly it will be a tough job to re-assemble. This is a sketch of the in-wheel snap ring idea:  The locking collar is a better idea, especially if a thrust bearing can be had from the same source. It would require more "angle iron" material to get from the outer mounting bolts to the wheel side of the collar/thrust bearing. | |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5981

Posts : 2645

Location : Indiana

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 17th 2019, 6:03 am June 17th 2019, 6:03 am | |

| I definitely wouldn’t cut the axle right there for an e clip or snap ring. Collar sounds much better but I’m sure you can get this thing apart and fix it right. Might need a screw/bolt extractor for the Allen bolts | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 25th 2019, 12:56 am June 25th 2019, 12:56 am | |

| Been busy for 10 days but I bought the collar, didn't use it, installed a 5 speed FooTe transaxle that has the same exterior case. I'm very new to Lawn Tractors and I discovered that up to now I had no brakes due to seized pins. Cleaned them up and adjusted them from memory of a video seen the night before. Made them so tight they locked the wheels. So I un-tighted them and it seems to work normal, forward, N, reverse.

This morning they seem to be locked up again as I couldn't push the mower in any gear or with clutch depressed(which applies brakes, counter-productive)

The first time after the new axle I just reached under there & turned the adjuster out s half turn or so, then it was fine.

Today I didn't want to do that so I left it sitting where it is.

Does the brake commonly tighten itself as it runs or sits? Could somebody be playing a trick on me?

| |

|

| |

CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5981

Posts : 2645

Location : Indiana

| |

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15675

Posts : 10987

Location : Oklahoma

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 25th 2019, 9:13 am June 25th 2019, 9:13 am | |

| - Tour1 wrote:

- Ok, next time I'll start a new thread.

I used a steering wheel puller to get the pulley off by drilling & tapping 2 existing holes out to 3/8-16.

I was following the Peerless manual which said to take out the set screw, spring, and ball that acts as the detente for each gear. There are 2 set screws on my trans, which says FooTe 3864 on the bottom of it and FooTe 3865 on the top. I couldn't get the set screws out & one is now mush, only drilling & tapping will fix it unless it comes out by magic. If the set screws need to be out for re-assembly it will be a tough job to re-assemble.

This is a sketch of the in-wheel snap ring idea:

The locking collar is a better idea, especially if a thrust bearing can be had from the same source.

It would require more "angle iron" material to get from the outer mounting bolts to the wheel side of the collar/thrust bearing.

You are OK, it was another member that was posting their Transaxle issue on your topic. I removed their part of the conversation to his own topic. Carry on as you normally would!

Last edited by MightyRaze on June 25th 2019, 9:20 am; edited 1 time in total | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 25th 2019, 9:15 am June 25th 2019, 9:15 am | |

| I was trying to push it in neutral. It's still very loud (skipping the details to avoid another thread-jack warning) and I just wanted to push it into the shade. It rocked a little but 1 tire skidded until I lost patience. I was just brushing on some paint for 1/2 hour before work and I did it in the hot sun instead of an extended troubleshoot process. Today it's raining so more thought than action again. Sorry for the long & complex details.

I'm expecting the shifter cut-out for the 4 speed is working the same now that it's a 5 speed, but one change was that I have to push the shifter past the neutral point a little to get it into neutral, so without the engine running and clutch engaged I'm not sure it's neutral unless the tractor rolls freely.

Before I parked it it ran ok, all gears, reverse, & neutral worked as far as I could tell.

| |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15675

Posts : 10987

Location : Oklahoma

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  June 25th 2019, 9:19 am June 25th 2019, 9:19 am | |

| - Tour1 wrote:

- I was trying to push it in neutral. It's still very loud (skipping the details to avoid another thread-jack warning)

Be as detailed as you like. It is your topic. I'm sure you haven't seen my previous post as it was posted soon before yours. | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  July 1st 2019, 3:31 am July 1st 2019, 3:31 am | |

| Just to finish this off, I took another 1/2 turnoff the brake adjuster and now it rolls good (again).

The gears feel normal, neutral is at the zig-zag where it's supposed to be, haven't had the time to try all gears.

| |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  November 24th 2019, 12:00 am November 24th 2019, 12:00 am | |

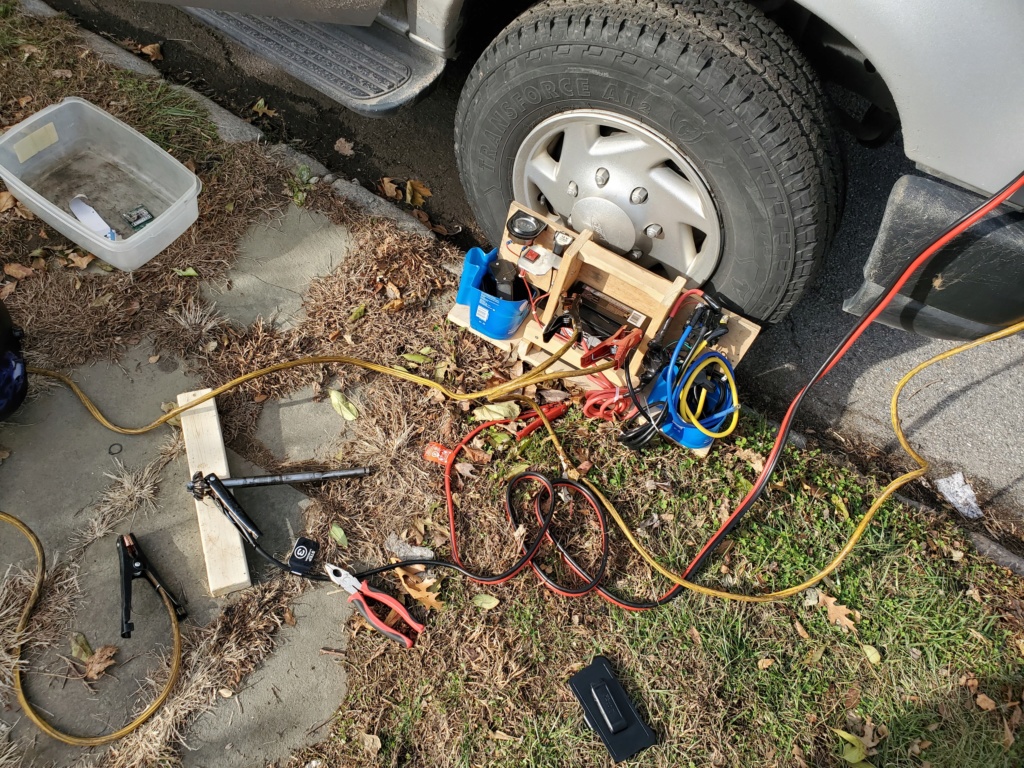

| I got the thing open by drilling out one of the screws in the middle of the case. The others came out ok and once it was open I took the remainder of the screw out with vise-grips. I found the snap ring in the bottom of the case, intact but unraveled. I think the shaft was worn enough so the groove didn't hold. The snap ring was more like a key ring but flattened so it looks like a piston ring. I figure I couldn't get one easy so I put some tack welds where the snap ring should be. I posted elsewhere about making welds using 12 volt batteries in series and that was my option today. I had bought a helmet and 1/16" rods so I could try it again. I used my van battery and a powersports glass mat battery that I use for my winch, so the wood box and some cables are for the winch, not being used to weld.  Apologies if the pics are out of order. The middle one should be the tack welded bevel gear on the shaft.  The tack welds were bigger than the snap ring so I had to grind them down. I took some off the end of the shaft because I might have welded the gear too far from the end and it wouldn't fit in the case when all the parts were present.  The transaxle is assembled and seems to work but I'm afraid I might have left out a thrust washer on the middle shaft assembly that drives the sun gear on the final. I took it out briefly when fitting the axles and differential and I later found a washer where I had put the assembly. It fits the brake shaft and not the wheel axles. | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  November 26th 2019, 10:09 am November 26th 2019, 10:09 am | |

| PS: I popped it open again and couldn't find anyplace missing a washer in there, I think it must be from the brake or drive pulley.

I noticed there are pockets in the casting near the wheels where roller bearings might fit. I expect they leave them out for the 4 speed.

Do you think that adding the right bearings there could make the transaxle suitable for "ground engaging implements"? My tractor also uses the inner set of mounting holes, using the ones closer to the wheels would also make it stronger. | |

|

| |

MightyRaze

Administrator

2017 Build-Off Finalist

2017 Build-Off Finalist

2018 Build-Off Top 3 Winner

2018 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2019 Build-Off Top 3 Winner

2021 Winner of Winners

2021 Winner of Winners

1st Place Build-Off 2022

1st Place Build-Off Winner 2022

10,000 POSTS!

10,000 POSTS!

2024 Build-Off Entrant

2024 Build-Off Entrant

Age : 49

Join date : 2016-09-06

Points : 15675

Posts : 10987

Location : Oklahoma

| |

| |

AllisKidD21

Moderator

2020 Build-Off Entrant

2020 Build-Off Entrant

1st Place Build-Off 2019

1st Place Build-Off Winner 2019

Age : 25

Join date : 2016-07-10

Points : 8587

Posts : 5190

Location : Ontario Canada

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  November 26th 2019, 1:26 pm November 26th 2019, 1:26 pm | |

| Nice job on the spider gear fix, I had to do that to a trans once when the little steel wraps kept popping off and the axle would slide out. What a pain. Held up fine after I welded them on though.

About the ball bearing upgrade, I'm not sure I'd say it would make it useable for ground engaging equipment, but it would definitely help the strength and reliability some. What were you planning on using if for? Some light work like pulling a harrow or a little cultivator would probably be okay, but I wouldn't go putting a 10" moldboard behind it, haha.  "This'll either wake you up or put you to sleep forever!"- Red Green "Whatever you do you should do right, even if it's something wrong." - Hank Hill - MTD Off-Road Build

- Ford LT 110 Off-Road Build

- Craftsman GT 6000 Off-Road Build

- Sears LT11 Rat Rod Build *2019 Build-Off Winner!* Garden Tractor Collection: Allis B-110 x2, 710, 716, & 410 - Wheel Horse 655, 953 & 500 Special - Case 444 - Bolens Versamatic, G10 & 1668 Diesel Swapped - Cub 106, 124 & 1000/149 Frankentractor - Ford 120, LGT 125 & 145 - White 1650 Yard Boss - Moto Mower 710-100 | |

|

| |

Biggkidd

New Member

Join date : 2019-11-11

Points : 1860

Posts : 15

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  November 26th 2019, 4:23 pm November 26th 2019, 4:23 pm | |

| Those axle retainers usually come out after someone beats on the inside of the wheel trying to get it off. Just an fyi. | |

|

| |

Tour1

Member

Join date : 2019-03-15

Points : 2195

Posts : 81

Location : Nassau and Sullivan counties, NY

|  Subject: Re: Tour1 Transaxle issue Subject: Re: Tour1 Transaxle issue  November 27th 2019, 10:53 am November 27th 2019, 10:53 am | |

| I beat the heck out if the other one getting the wheel off, the one that failed was done by a previous owner.

My plans are to have a grown-up tonka toy that can do some work on steep rocky land. I am moving towards a "build" of a self-propelled generator using the 5-speed if I put the 4 speed back in the tractor. If that works maybe the tractor will only cut grass and move snow downstate. | |

|

| |

Sponsored content

| |

| |

| | Tour1 Transaxle issue |  |

|