|

| | Hutch's Sears LT-10 Build |  |

| | | Author | Message |

|---|

hutch17

New Member

Join date : 2014-08-09

Points : 3775

Posts : 11

|  Subject: Hutch's Sears LT-10 Build Subject: Hutch's Sears LT-10 Build  May 31st 2016, 12:23 am May 31st 2016, 12:23 am | |

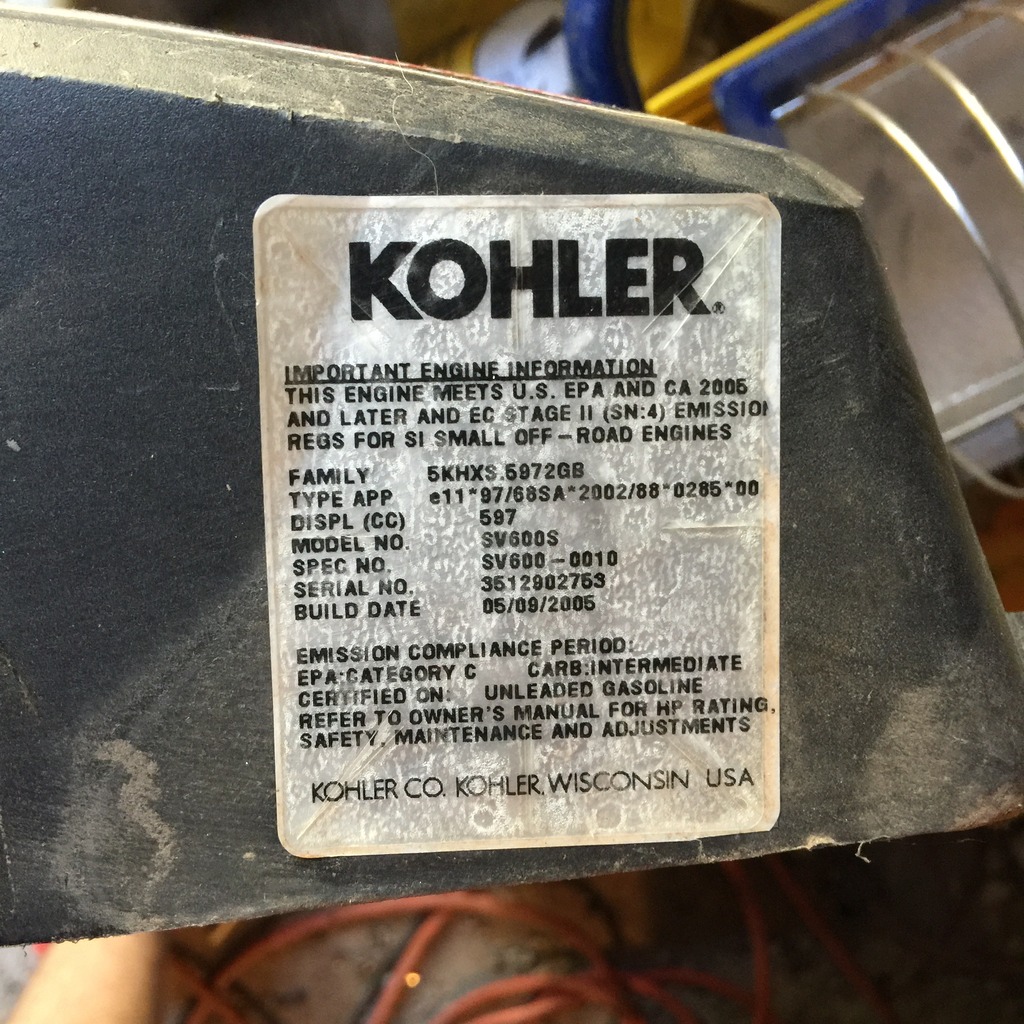

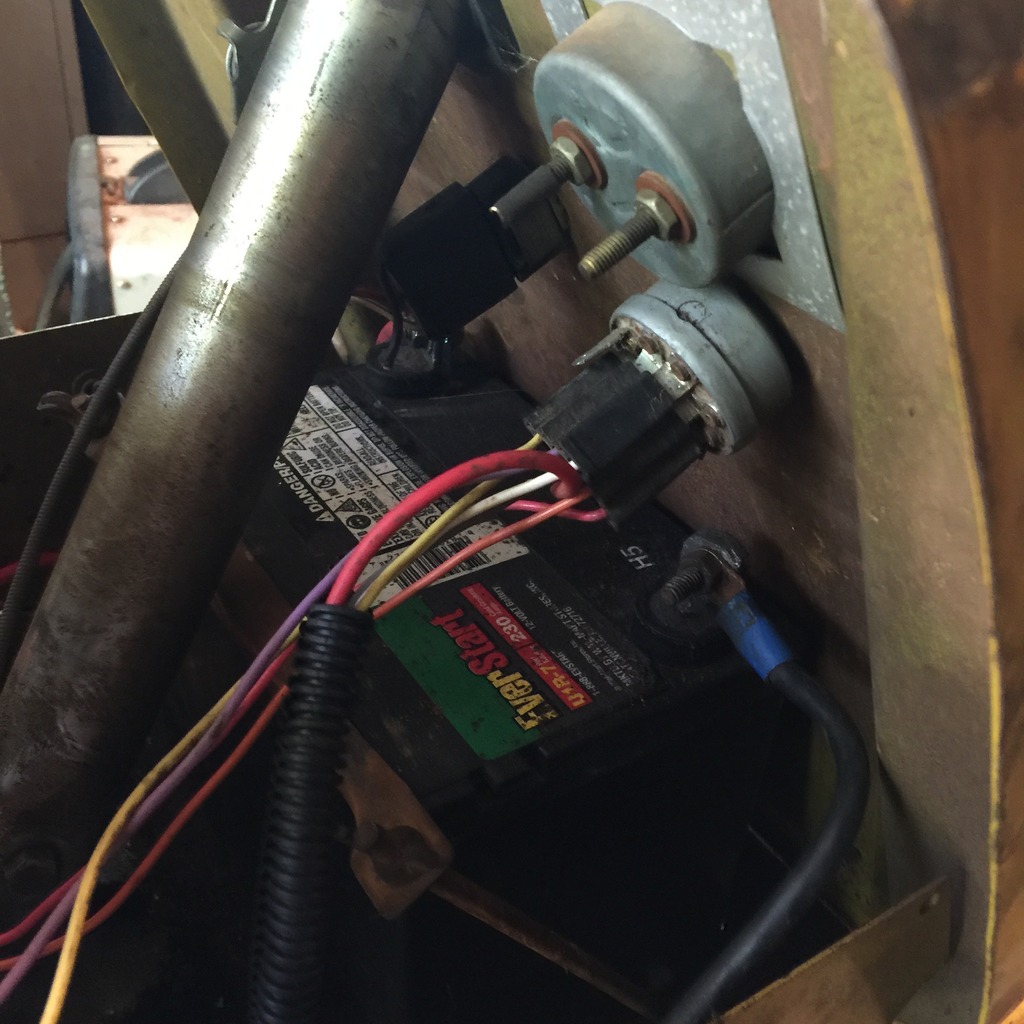

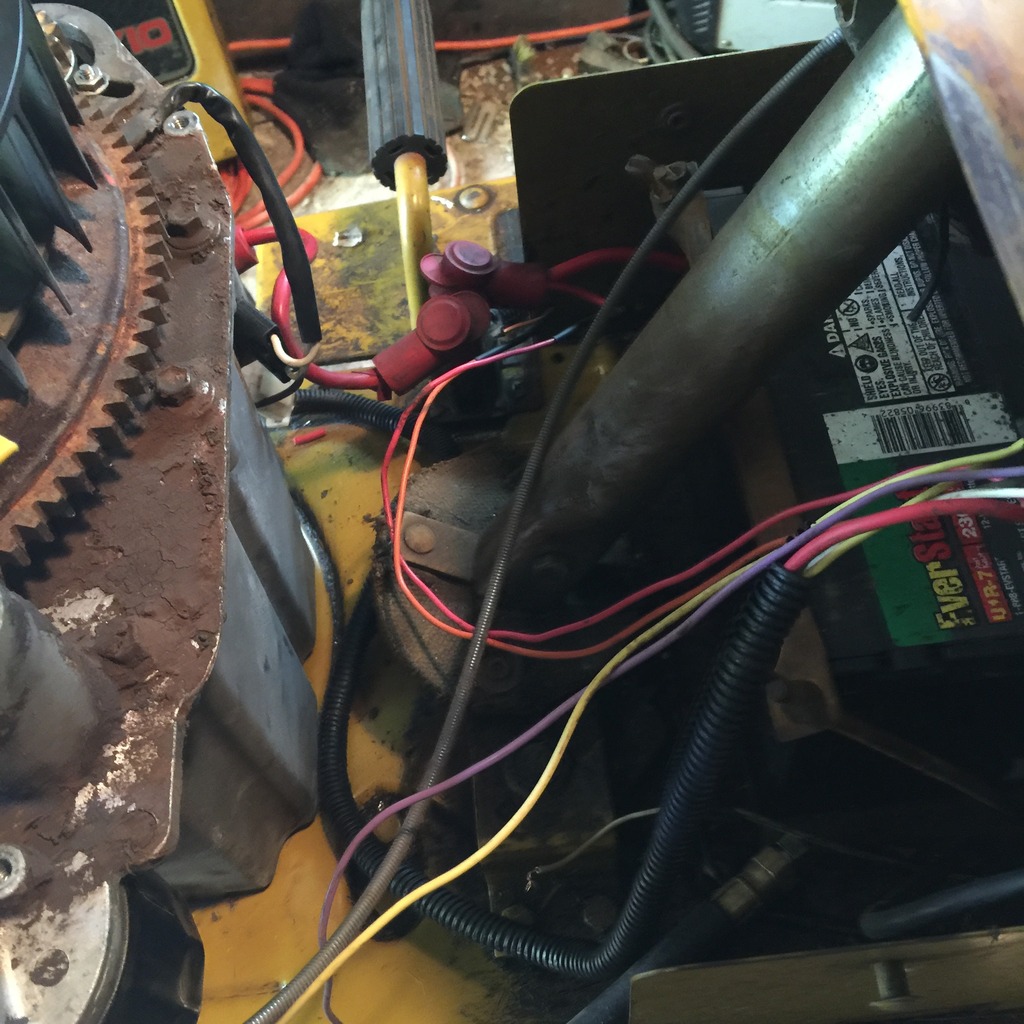

| Hello ladies and gents! Ive stalked this form for a while and have learned a lot and have enjoyed a lot of different builds. I thought it would be fitting to post up my most recent project. I picked up a Sears LT-10 from a friend for $20, it did not run, the tires were flat and the battery was shot. This is what it looked like when I got it home  I had picked up a murry lawn tractor a few weeks prior with hopes to fix it up but that project got put on hold when I locked the trans and broke the weld and have been unable to get the bolts out of the case. I have since cannibalized that tractor and have used a few different parts off of the murry on the sears such as the wiring harness, rear wheels and tires, battery, and a few other parts that I cant think of off the top of my head. A friend of mine had a craftsman zero turn that blew both hydro motors so he stripped it for what was of value and scrapped the rest. It had a 20 hp kohler motor among other things on it that he saved. He had no use for the kohler motor so he passed it on to me as he knew it would be used for something. Prepping for the new power plant  the new motor   Its new resting place   Mocking up the grille and exhaust   The wiring harness off of the mury    I had to find a solution for a gas tank as the old motor was all one package so I stole the under seat one from the murry   After this point I ran it, broke it, fixed it and then broke the rubber disk that acted as a universal joint for the steering. After that I parked it in the garage and it sat there until about a month ago when I got bored and decided to dig it out. Since then I have fixed the universal in the steering by taking a 1/2 inch impact universal socket and welding it into the steering shaft and onto the bar at the bottom and vala bomb proof steering universal. After I got it driving I ran it around a bit and realized the tires suck in the mud so I looked up a few threads on cutting tread and got some ideas together. I ended up cutting every other line of treads and alternating on the other side of the tire it looks like this: IIIIIII IIIIIII IIIIIII IIIIIII IIIIIII IIIIIII Needless to say it helped tremendously in the traction department. I also added a set of work lights on a bar I welded to the existing plow frame and wired it to the existing aux light switch. I had a crappy work light on the rear of the tractor but backed into something and broke it off, its soon to be replaced with an led work light. I also messed with the exhaust some and made a custom muffler and exhaust stack which is ridiculously loud at this point almost hurts my ears to drive it lol. Here are some current pictures of it   Me with my future tool grabber  | |

|   | | hutch17

New Member

Join date : 2014-08-09

Points : 3775

Posts : 11

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  May 31st 2016, 12:34 am May 31st 2016, 12:34 am | |

| Question, does anyone know how to quiet this thing down some? Its very very loud and annoying haha | |

|   | | 1997 Murray

Veteran Member

2014 Build-Off Finalist

2014 Build-Off Finalist

2015 Build-Off Finalist

2015 Build-Off Finalist

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 26

Join date : 2013-11-13

Points : 5447

Posts : 1311

Location : NW USA

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  May 31st 2016, 11:51 am May 31st 2016, 11:51 am | |

| Those kohlers are extremely loud for some reason. Maybe you could get another muffler to put in before the stack and you would have dual mufflers to quiet it down. | |

|   | | CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5982

Posts : 2645

Location : Indiana

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  May 31st 2016, 12:36 pm May 31st 2016, 12:36 pm | |

| Those Kohler Courage engines aren't known to be built very well. I like the idea of a twin cam single cylinder, but the cams are plastic and the crankcase casting is a little on the thin side. *If it were me* I would leave the governor on and gear it high for the speed you want. Obviously, it's your machine and you can do what you want. But I like the look of the build and I think it'll perform just fine.  | |

|   | | hutch17

New Member

Join date : 2014-08-09

Points : 3775

Posts : 11

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  May 31st 2016, 5:32 pm May 31st 2016, 5:32 pm | |

| at this point the pulleys are stock sized. I wont be messing with the governor at all. What pulley sizes would you recommend to get some more speed out of it. Not looking for anything crazy fast. | |

|   | | CraftsmanQuad19

Veteran Member

2018 Build-Off Entrant

2018 Build-Off Entrant

2019 Build-Off Finalist

2019 Build-Off Finalist

Age : 24

Join date : 2016-04-12

Points : 5982

Posts : 2645

Location : Indiana

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  May 31st 2016, 8:53 pm May 31st 2016, 8:53 pm | |

| The best ratio to run is about 1:1. i use 4.75 up front and a 4 inch in the rear. For me, this is about 17-19 mph. Your 20 horse should to that easily.

Fearless runs a 5 front and 4 rear last I checked, with a 14.5 briggs. | |

|   | | Rockinator

Member

2016 Build-Off Entrant

2016 Build-Off Entrant

Age : 23

Join date : 2016-01-16

Points : 3410

Posts : 164

Location : Canada

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  June 1st 2016, 9:16 pm June 1st 2016, 9:16 pm | |

| Thats a neat look to the grille! Love those machines! I own two myself, the frames are awesome for building a mower on, and could you post pics of the steering? I need to fix mine, and need some ideas. (Going to be used for racing) | |

|   | | hutch17

New Member

Join date : 2014-08-09

Points : 3775

Posts : 11

|  Subject: Re: Hutch's Sears LT-10 Build Subject: Re: Hutch's Sears LT-10 Build  June 5th 2016, 10:45 pm June 5th 2016, 10:45 pm | |

| - Rockinator wrote:

- Thats a neat look to the grille! Love those machines! I own two myself, the frames are awesome for building a mower on, and could you post pics of the steering? I need to fix mine, and need some ideas. (Going to be used for racing)

Ill try to get some pictures my phone is messed up and take ***** pics. Basically, the larger diameter part of the universal socket is inserted into the steering shaft the steering wheel attaches to. And the part that would go into a standard socket is welded to the piece that has the gear on it. if you follow my, kinda hard to describe | |

|   | | Sponsored content

| |   | | | | Hutch's Sears LT-10 Build |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| | Who is online? | In total there are 37 users online :: 0 Registered, 0 Hidden and 37 Guests

None

Most users ever online was 412 on January 7th 2023, 7:59 am

|

|